Integrated treatment method of chemical flooding produced emulsion

A treatment method and emulsion technology, applied in chemical instruments and methods, mining wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problem of difficult to meet the standards of crude oil transportation and sewage geological injection and aggregation, thermogravity settlement Efficiency reduction, aging oil circulation increase, etc., to avoid the generation of aging oil and the generation of oily sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

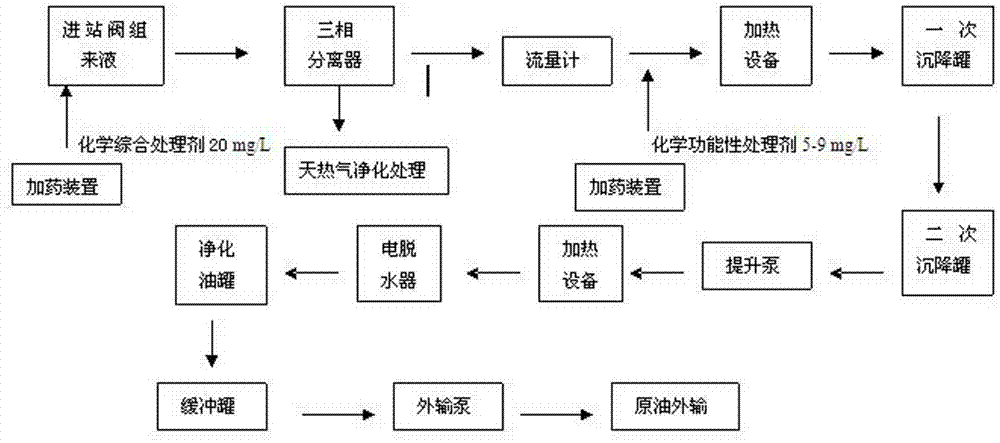

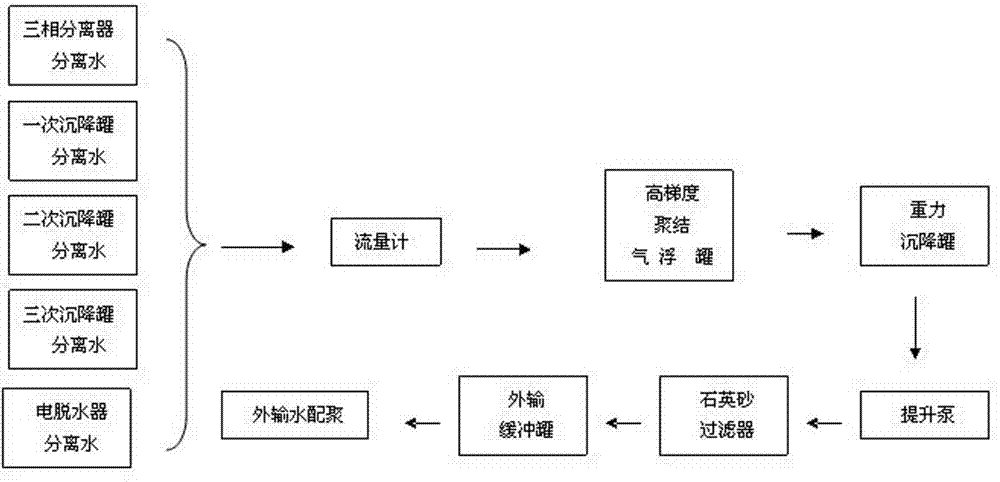

[0016] In order to further disclose the technical solution of the present invention, the following will be described in detail in conjunction with the accompanying drawings in the description:

[0017] The present invention integrates the crude oil treatment process with the sewage treatment process, optimizes the oil-water treatment equipment, selects suitable demulsifiers and water treatment agents, and rationally arranges dosing positions, so that the emulsion produced by chemical flooding is transported in the oil-water integrated treatment process. Transfer and treatment, so that the water content of the exported crude oil reaches 0.6%, the oil content of the exported sewage is 9.3mg / L, the suspended solid content is 8.0mg / L, the polymer content is 242mg / L, and the polymer retention rate of the polymer-containing sewage is above 95%. Reduced the production of aged oil and oily sludge.

[0018] The present invention has carried out on-the-spot test on the integrated pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com