Aluminum plastic film

A technology of aluminum-plastic film and outer layer, which is applied in the field of aluminum-plastic film, can solve problems such as inability to join, decrease in efficiency, and inability to meet the speed of bonding projects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

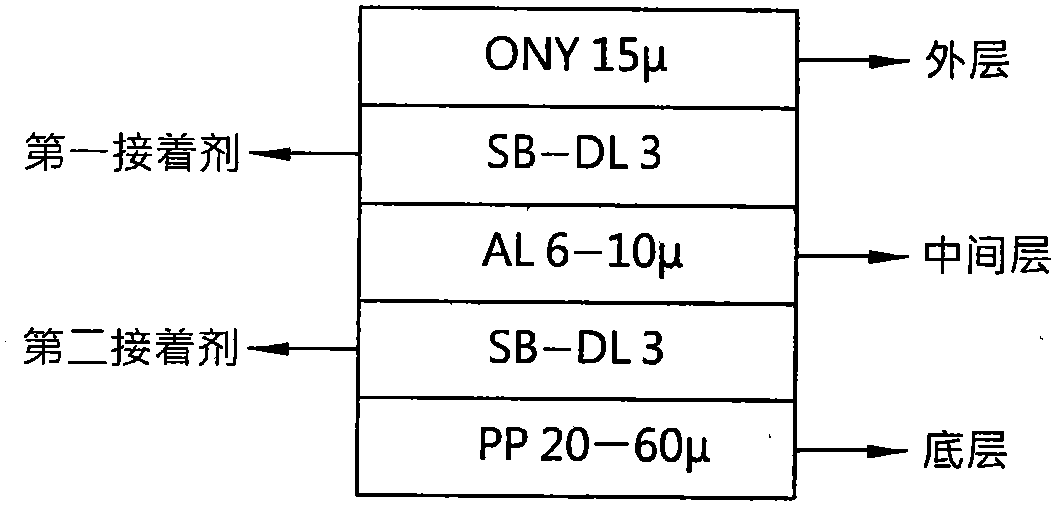

[0070] First, an aluminum-plastic film of the present invention, the first embodiment, as Figure 4 As shown, it includes an outer layer, a first bonding layer, a first primer layer, an intermediate layer, a second primer layer, a second bonding layer and a bottom layer, and the outer layer is nylon film (ONY) , as the main material, the thickness is about 15μ to 25μ, with friction resistance, elongation and tensile strength. The outer substrate can be printed without printing or printed on the inner surface or surface. The printing is based on water-based ink-WB-Ink ( Water Base Ink) is printed on the outer layer. The first adhesive layer is an adhesive, which combines the inner surface of the outer layer with an intermediate layer. The first adhesive layer is a solvent-free adhesive-NSB (NON-Solvent Base) , the first adhesive layer may be an organic solvent-based adhesive-SB (Solvent Base), the first primer layer is a functional treatment layer, which has the structural char...

no. 2 example

[0073] Second embodiment, such as Figure 5 As shown, it includes an outer layer, a first adhesive layer, a first primer layer, an intermediate layer, a second primer layer, a second adhesive layer and a bottom layer, and the outer layer is a polyester film (PET ) 12μ plus nylon (ONY) 15μ, as the main material, has friction resistance, elongation and tensile strength. The outer substrate can be unprinted or printed on the inner surface or surface. The printing is based on water-based ink-WB-Ink (Water Base Ink) is printed on the outer layer. The first adhesive layer is an adhesive, which combines the inner surface of the outer layer with an intermediate layer. The first adhesive layer is a solvent-free adhesive-NSB (NON-Solvent Base Ink) ), or it can be an organic solvent-based adhesive-SB (Solvent Base), the first primer layer is a functional treatment layer with a structure of high moisture resistance and high gas barrier, the first primer layer is a modified acrylic PMMA, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com