Highly dispersed carbon nanotube carried catalyst and preparation method of precursor thereof

A technology of carbon nanotubes and catalysts, applied in the field of preparation of highly dispersed carbon nanotube-supported catalysts and their precursors, can solve the problems of catalyst loss, reducing the stability of carbon nanotubes, and destroying the structural integrity of carbon nanotubes , to achieve the effect of simple operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the precursor of the carbon nanotube-carried catalyst according to an embodiment of the present invention comprises:

[0028] - dissolving the noble metal salt and / or the transition metal salt in a volatile non-protonated polar solvent such as furan, tetrahydrofuran or a mixture thereof to obtain a homogeneous solution,

[0029] -then, adding a designed amount of carbon nanotubes into the above solution,

[0030] - Ultrasonic dispersion of carbon nanotubes uniformly added to the above solution,

[0031] -Alternately heating, stirring, concentrating and ultrasonically dispersing the above-mentioned solution added with carbon nanotubes until a paste carbon mud is obtained,

[0032] - place the above paste carbon mud for 12 hours, so that the metal salt can be fully adsorbed on the surface of the carrier,

[0033] - Then, put the above paste carbon mud in an oven and bake, so as to obtain the precursor of carbon nanotube-supported metal or alloy...

Embodiment 1

[0052] - 0.33g PdCl 2 dissolved in 10 mL of furan,

[0053] - adding 0.8 g of multi-walled carbon nanotubes to the above solution,

[0054] - homogeneous dispersion by ultrasound,

[0055] -Repeatedly heat, stir, concentrate and ultrasonically disperse until a paste carbon mud is obtained,

[0056] -Stand for 12 hours

[0057] -Put it in an oven at 60°C to bake and dry,

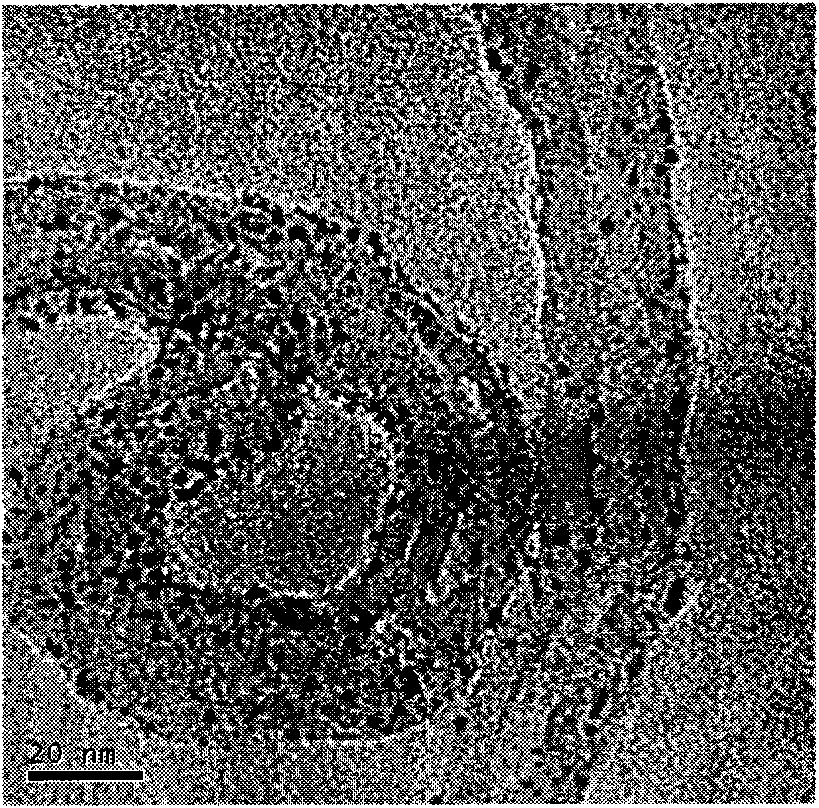

[0058]- Grind the dried precursor and place it in a porcelain boat in a tube furnace, at 150°C in H 2 Reduction in the atmosphere for 2h, and then cooled to room temperature to obtain 20wt% highly dispersed Pt / MWCNTs catalyst. Figure 1A It is the transmission electron micrograph of the catalyst obtained in this example. From Figure 1A Middle view to see that Pd metal nanoparticles are uniformly dispersed on the surface of carbon nanotubes.

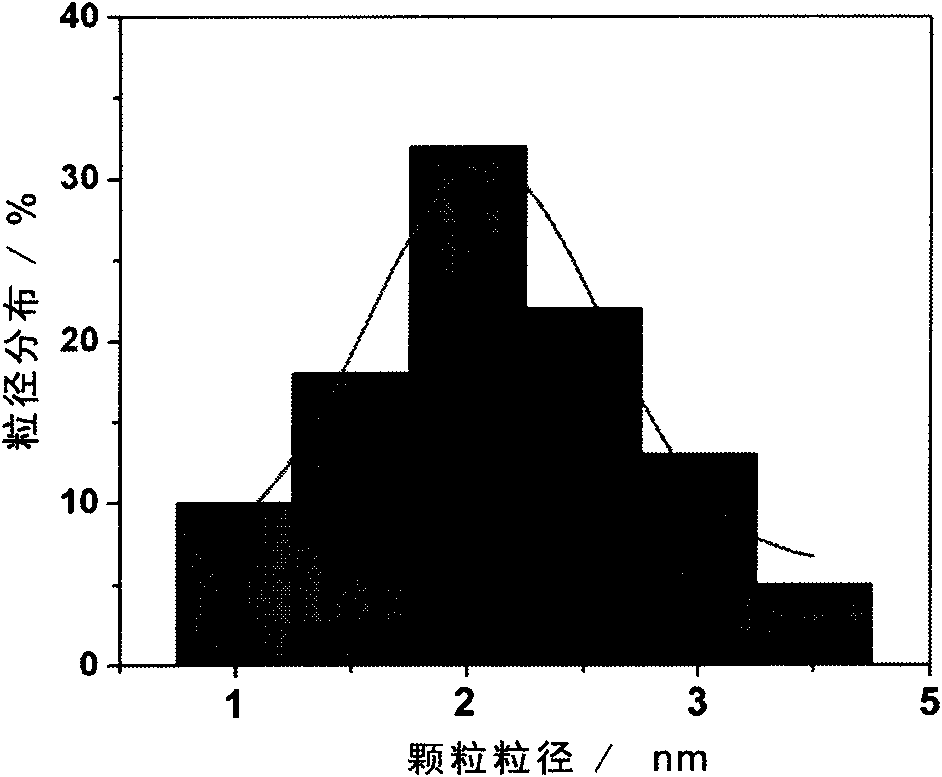

[0059] From Figure 1A The particle size of nearly 300 nanoparticles is randomly counted, and the statistical results of particle size distribution can be found i...

Embodiment 2

[0061] - 0.627g HAuCl 4 4H 2 O was dissolved in 10 mL THF,

[0062] - adding 0.7 g of multi-walled carbon nanotubes to the above solution,

[0063] - homogeneous dispersion by ultrasound,

[0064] -Repeatedly heat, stir, concentrate and ultrasonically disperse until a paste carbon mud is obtained,

[0065] -Stand for 12 hours, then bake and dry in an oven at 60°C,

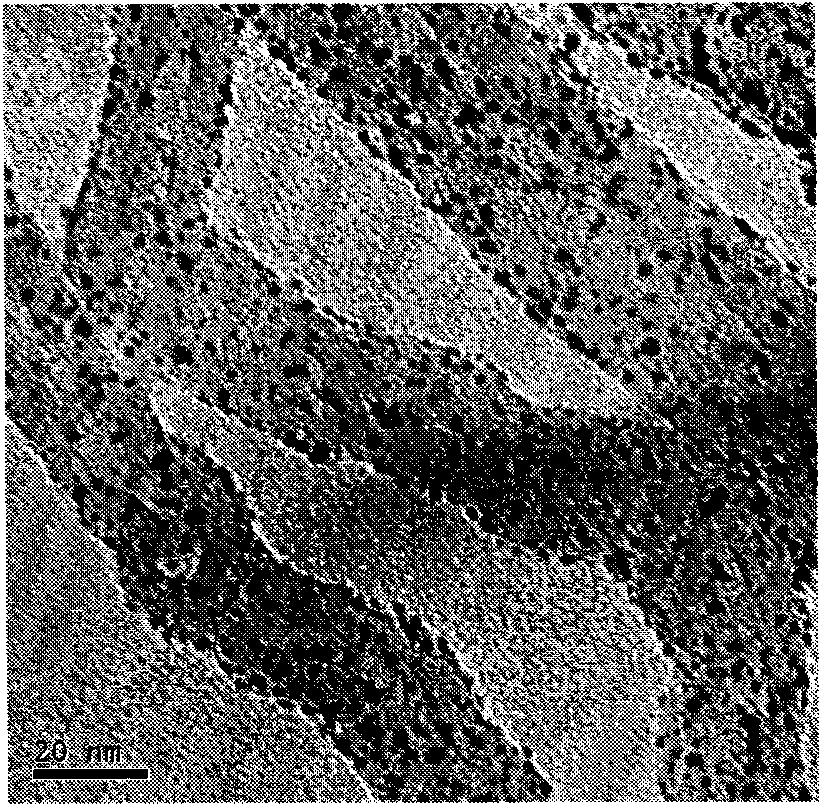

[0066] - Grind the dried precursor and place it in a porcelain boat, in a tube furnace at 120°C under H 2 Reduction in the atmosphere for 2h, and then cooled to room temperature, 30wt% highly dispersed Au / MWCNTs catalyst was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com