Adsorbent for treating hexavalent chromium in neutral wastewater and preparation method of adsorbent

An adsorbent, hexavalent chromium technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., to achieve low cost, good regeneration performance, simple and convenient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

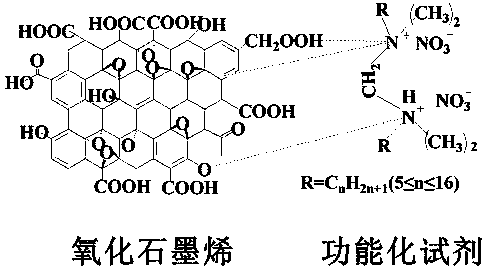

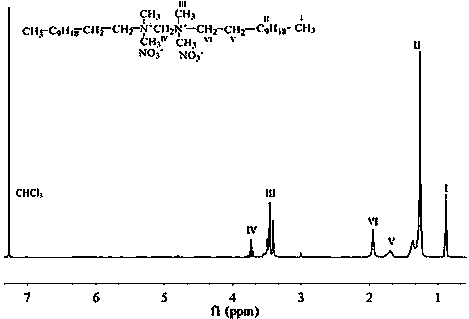

[0032] The quality of tetramethylmethanediamine is 1 g, the quality of bromododecane is 5.5 g, dimethylformamide is used as solvent 3 mL, and the reaction temperature is 80 o C, reaction time 12 h; recrystallize three times with ethanol-ethyl acetate to obtain product I; dissolve product I in ethyl acetate and 20 mL, react with 3mol / L NaOH solution, wash with deionized water several times until neutral; continue and 20 mL, 4mol / L of HNO 3 reaction, washed with deionized water several times to neutrality, and obtained functionalized reagent I with a mass of 5.1 g; the desired structure was detected by NMR (see attached figure 1 ).

Embodiment 2

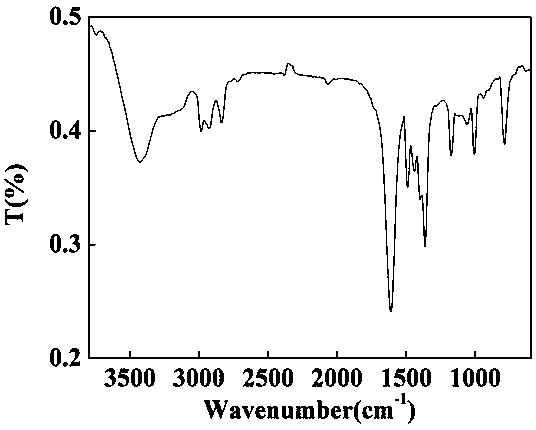

[0034] 0.5 g of functionalization reagent I was dissolved in acetone, 1 g of GO was ultrasonically dispersed in it, 25 o C stirred for 10 h, centrifuged, washed with deionized water, 60 o C vacuum drying for 12 h to obtain the functionalized graphene oxide I adsorbent, which was successfully loaded by infrared detection (see attached image 3 ), calculated according to the above method, the adsorption rate of Cr(VI) at pH=2-9 is greater than 96%, as shown in the following table:

[0035] pH

Embodiment 3

[0037] The quality of tetramethylmethanediamine is 1 g, the quality of bromoheptane is 4.3 g, 4 mL of acetonitrile is used as solvent, and the reaction temperature is 75 o C, reaction time 10 h; recrystallize three times with ethanol-ethyl acetate to obtain product II; dissolve product II in ethyl acetate and react with 20 mL, 3mol / L NaOH solution, wash with deionized water several times until neutral; continue and 20 mL, 4mol / L of HNO 3reaction, washed with deionized water several times until neutral, and obtained functionalized reagent II with a mass of 3.2 g; 0.5 g functionalized reagent II was dissolved in acetone, 1.0 g of GO was ultrasonically dispersed in it, and 30 o C stirred for 12 h, centrifuged, washed with deionized water, 60 o C was vacuum dried for 12 h to obtain functionalized graphene oxide II adsorbent, and the adsorption rate of Cr(VI) was calculated as 97.2% according to the above method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com