Plasma surface treatment equipment for granular and powdery materials

A technology of plasma and powder materials, which is applied in the field of plasma technology, can solve the problems that powder or metal powder cannot be processed, gas cannot be excited, and the processing capacity is small. good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

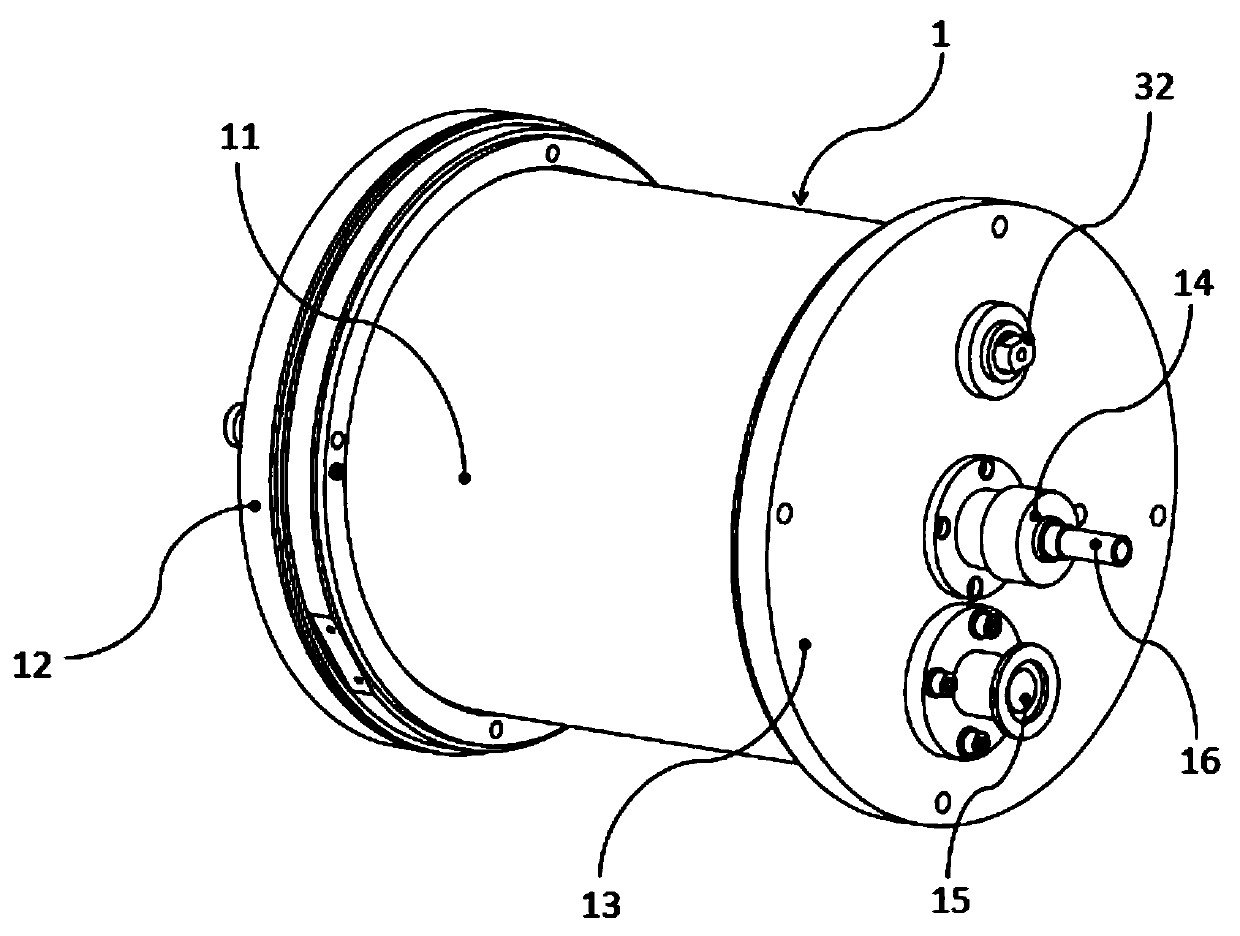

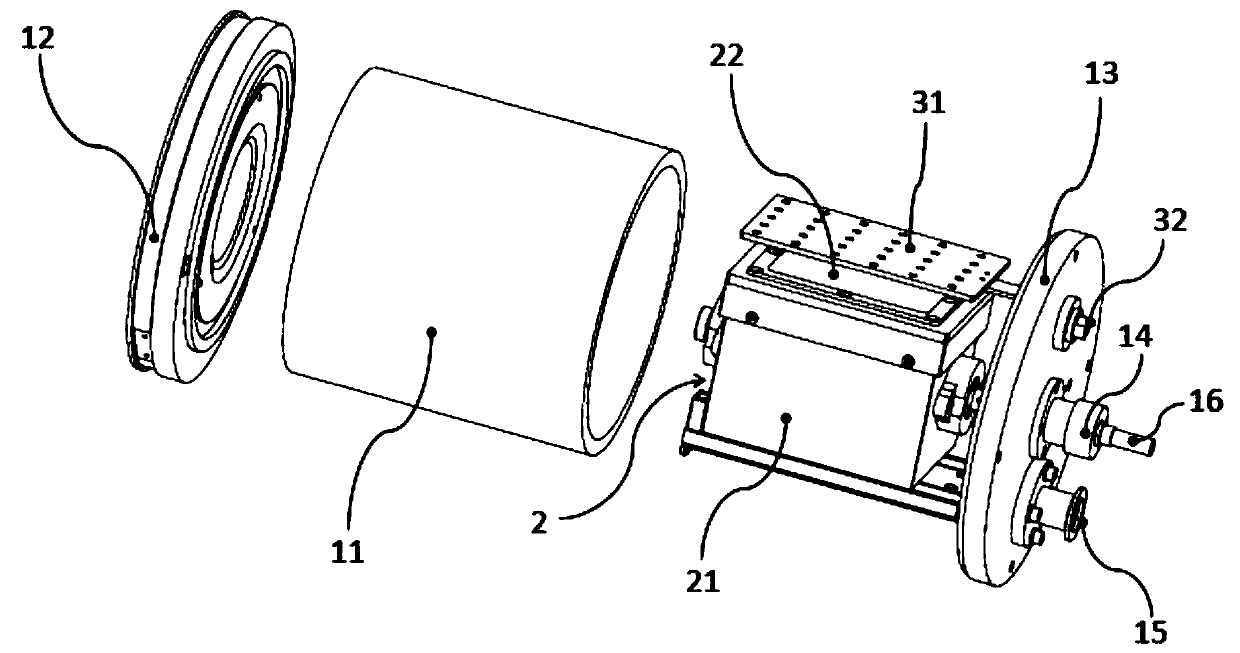

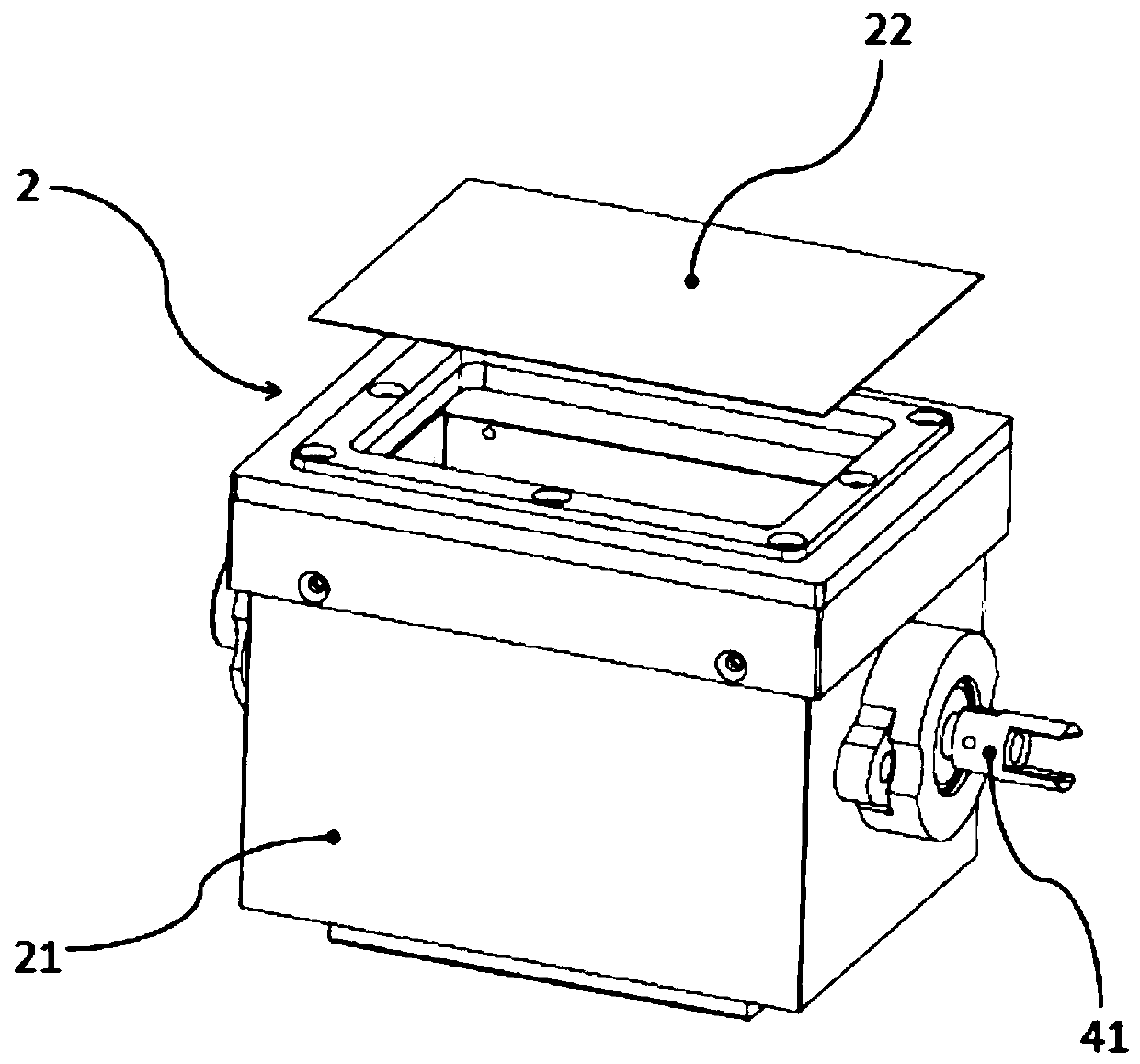

[0025] as 1- Figure 4 As shown, a plasma surface treatment equipment for particles and powder materials includes a vacuum outer chamber 1, a vacuum inner chamber 2, a particle stirring mechanism 4 and a plasma generator, and the vacuum inner chamber 2 is set in the vacuum outer chamber 1 , the particle stirring mechanism 4 is located in the vacuum inner cavity 2, and the plasma generator is located on the particle stirring mechanism 4; the right side of the vacuum outer cavity 1 is provided with a vacuum suction port 15 and an air inlet 14, and the The vacuum inner chamber 2 comprises a reaction chamber 21 and a filter screen 22, the top of the reaction chamber 21 is open, the filter screen 22 is arranged on the top of the reaction chamber 21, and the air inlet 13 communicates with the right side of the vacuum inner chamber 2; The plasma generator includes an electrode set 31 and a plasma generating power source, and the electrode set 31 is arranged above the filter plate 22 ...

Embodiment 2

[0032] as 1- Figure 4 As shown, a plasma surface treatment equipment for particles and powder materials includes a vacuum outer chamber 1, a vacuum inner chamber 2, a particle stirring mechanism 4 and a plasma generator, and the vacuum inner chamber 2 is set in the vacuum outer chamber 1 , the particle stirring mechanism 4 is located in the vacuum inner cavity 2, and the plasma generator is located on the particle stirring mechanism 4; the right side of the vacuum outer cavity 1 is provided with a vacuum suction port 15 and an air inlet 14, and the The vacuum inner chamber 2 comprises a reaction chamber 21 and a filter screen 22, the top of the reaction chamber 21 is open, the filter screen 22 is arranged on the top of the reaction chamber 21, and the air inlet 13 communicates with the right side of the vacuum inner chamber 2; The plasma generator includes an electrode set 31 and a plasma generating power source, and the electrode set 31 is arranged above the filter plate 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com