Solid-liquid two-phase mixed working medium suitable for electric discharge surface treatment

A surface treatment and working medium technology, which is applied in the field of solid-liquid two-phase mixed working medium for discharge surface treatment, can solve the problems of easy microcracks in the reinforced layer, uneven thickness and component distribution of the reinforced layer, and achieve good dispersion stability , good self-dispersion, and the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

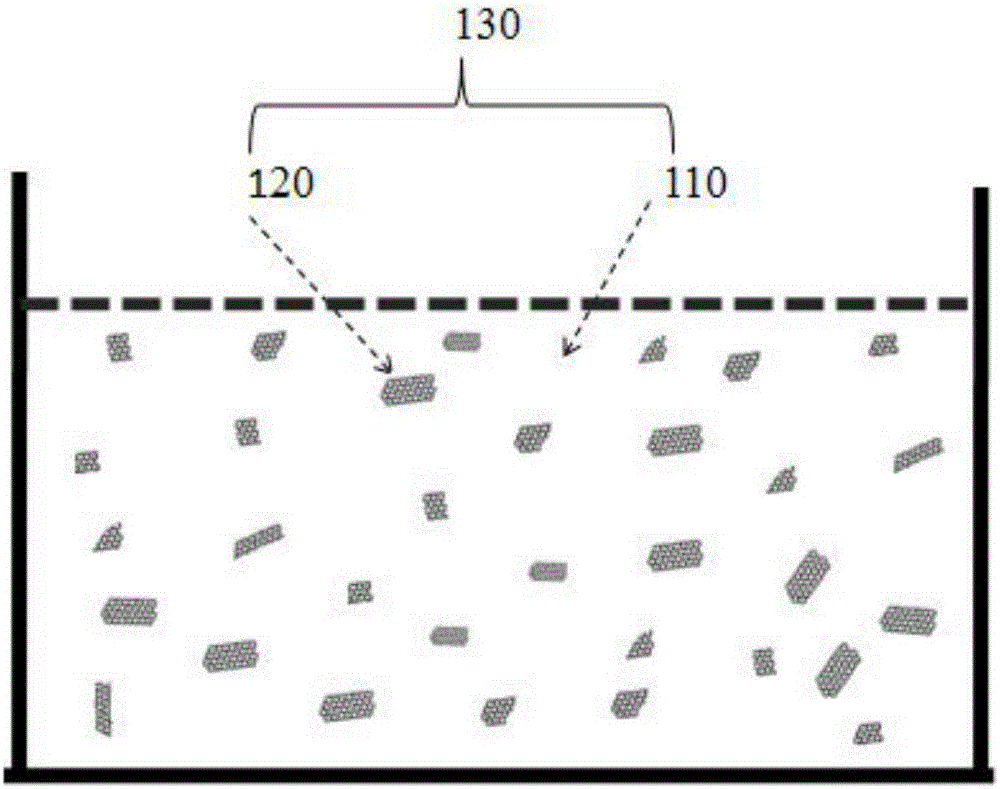

[0027] figure 1 It is a schematic diagram of the solid-liquid two-phase mixed working medium for discharge surface treatment of the present invention. Among them, 110 is an insulating liquid, 120 is a solid additive, and 130 is a solid-liquid two-phase mixed working medium for discharge surface treatment. The working medium 130 of the present invention includes an insulating liquid 110 and a solid additive 120 . The insulating liquid is kerosene, and the solid additive is one or more of graphene, two-dimensional boron nitride and two-dimensional titanium carbide.

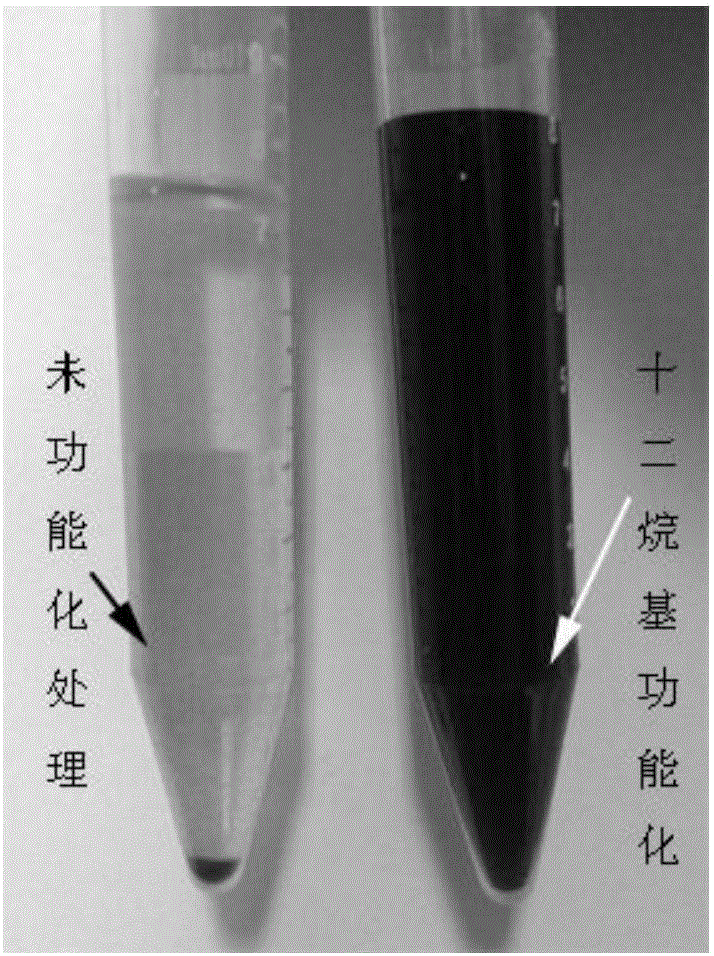

[0028] The solid additive in this example is graphene, which is modified by alkyl functionalization before mixing graphene with kerosene. It is a two-step method of acylation activation and amide reaction to graft an alkane with a carbon chain length of C12 to C18 on the surface of graphene. base functional group.

[0029] The steps of graphene alkyl functional modification are as follows: take 1 g of graphene co...

Embodiment 2

[0033] Unlike Example 1, in the step of graphene alkyl functional modification, the alkylamine liquid used is octadecylamine, thus obtaining octadecyl functionalized graphene. Octalkyl functionalized graphene is mixed with 1L kerosene, and ultrasonically dispersed for 30 minutes to obtain a concentration of 0.01gL -1 Octadecyl functionalized graphene / kerosene solid-liquid two-phase mixed working medium.

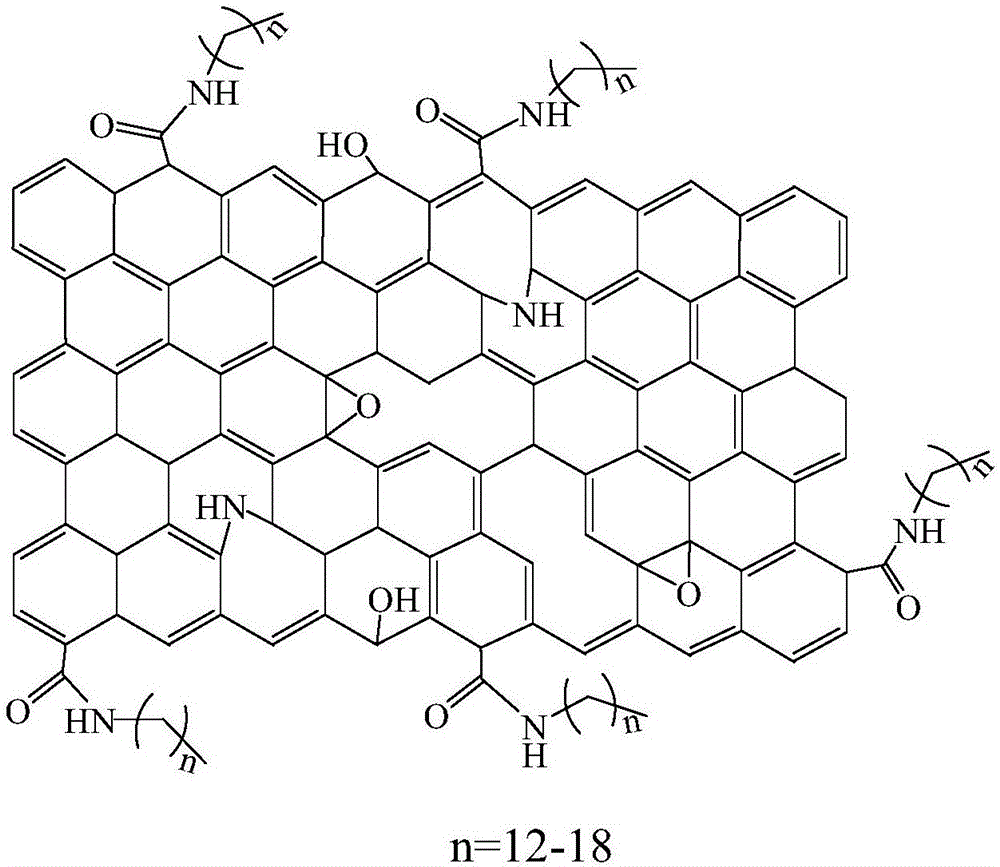

[0034] figure 2 It is a schematic diagram of the molecular structure of alkyl functionalized graphene in embodiment 1 and embodiment 2. Wherein, embodiment 1 is dodecyl functionalized graphene, and embodiment 2 is octadecyl functionalized graphene. Depend on figure 2 It can be seen that the -COOH functional group on the surface of graphene is replaced by -CO-NH(CH 2 )n-CH 3 (n=11 or n=17) functional groups are substituted, thereby realizing the dodecyl functional modification or octadecyl functional modification of graphene.

Embodiment 3

[0036] The difference from Example 1 is that the solid additive is two-dimensional boron nitride. Two-dimensional boron nitride is modified by alkyl functionalization before mixing with kerosene. In this example, an alkyl functional group with a carbon chain length of C12-C18 is grafted on the surface of two-dimensional boron nitride through acid chloride reaction.

[0037] The steps of two-dimensional boron nitride alkyl functional modification are as follows: take 1g surface containing -NH 2 Two-dimensional boron nitride powder with functional groups, ultrasonically dispersed in 1L dimethylformamide and dodecanoyl chloride mixture (volume ratio 3:7), under nitrogen protection atmosphere, reflux at 120°C for 48 hours, filter and vacuum at 100°C After drying, dodecyl functionalized two-dimensional boron nitride is obtained.

[0038] Take 0.5g of the above-mentioned dodecyl functionalized two-dimensional boron nitride and mix it with 1L of kerosene, and disperse it ultrasonica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com