Preparation method of novel Kevlar fiber enhanced multipurpose paper based on ultralong hydroxyapatite nanometer lines

A hydroxyapatite and Kevlar fiber technology, applied in the directions of synthetic cellulose/non-cellulose material pulp/paper, non-fibrous pulp addition, fiber raw material treatment, etc. pollution and other problems, to achieve the effect of simple preparation process, good flexibility and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

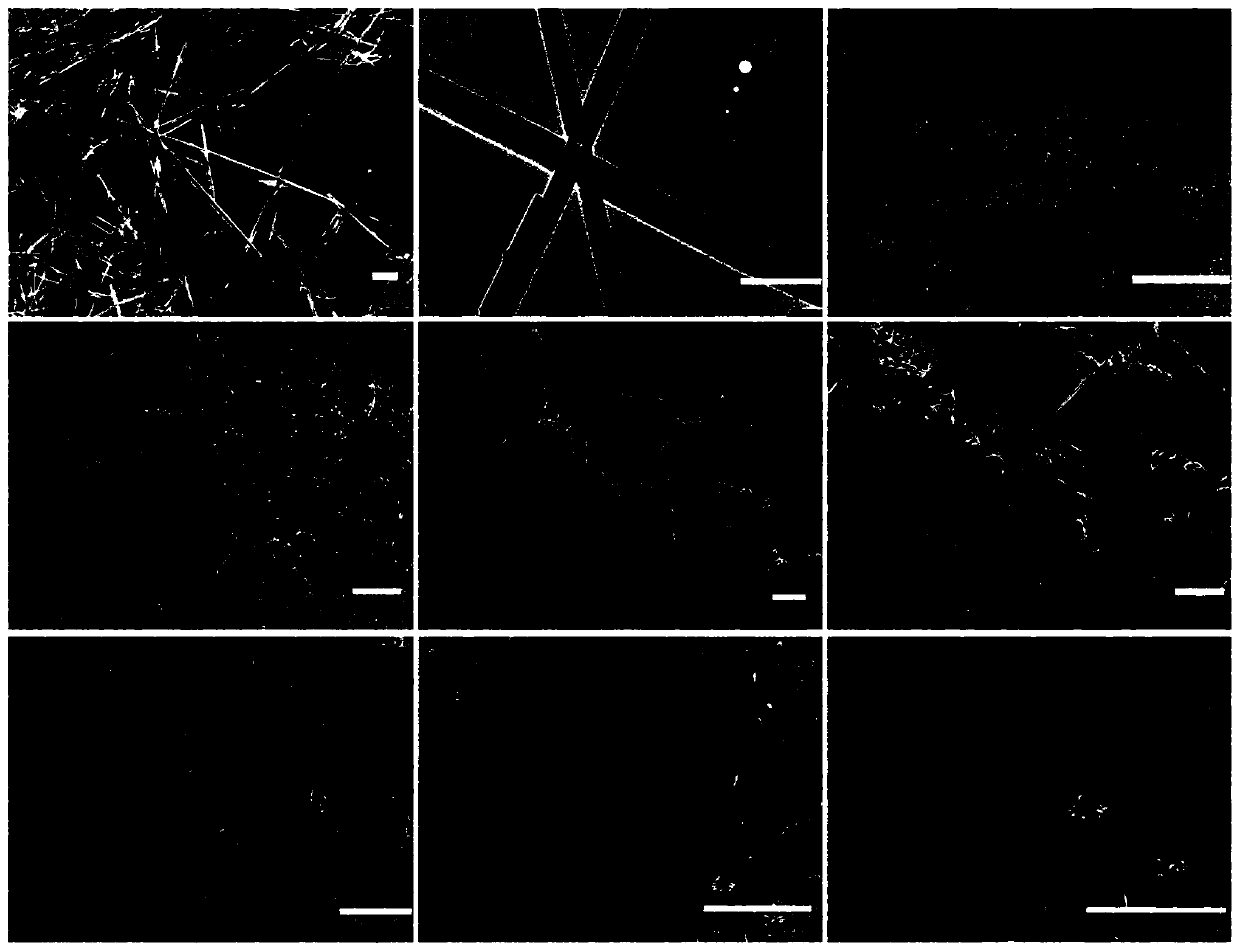

[0030] 1. Preparation of ultra-long hydroxyapatite nanowires: Add calcium chloride (0.22, 10ml) and sodium hydroxide solution (0.7, 10ml) to a mixed solution of oleic acid (7ml) and ethanol (7ml) to react for a period of time Then add a certain amount of sodium dihydrogen phosphate solution (0.29g, 10ml). Then transfer the obtained milky white reaction precursor into a high-temperature reaction kettle at 200° C. to react for 20 hours to obtain ultra-long hydroxyapatite nanowires.

[0031] 2. Preparation of nano-titanium dioxide: Mix 2ml of tetrabutyl titanate, 30ml of ethanol and 10ml of glycerin, stir at room temperature for 15min, then transfer to a high-temperature reactor at 175°C for 20h. The titanium dioxide nanoparticles obtained by the reaction are washed with ethanol and dried, and then baked at a high temperature of 400° C. for 2 hours to obtain flower-shaped titanium dioxide nanoparticles.

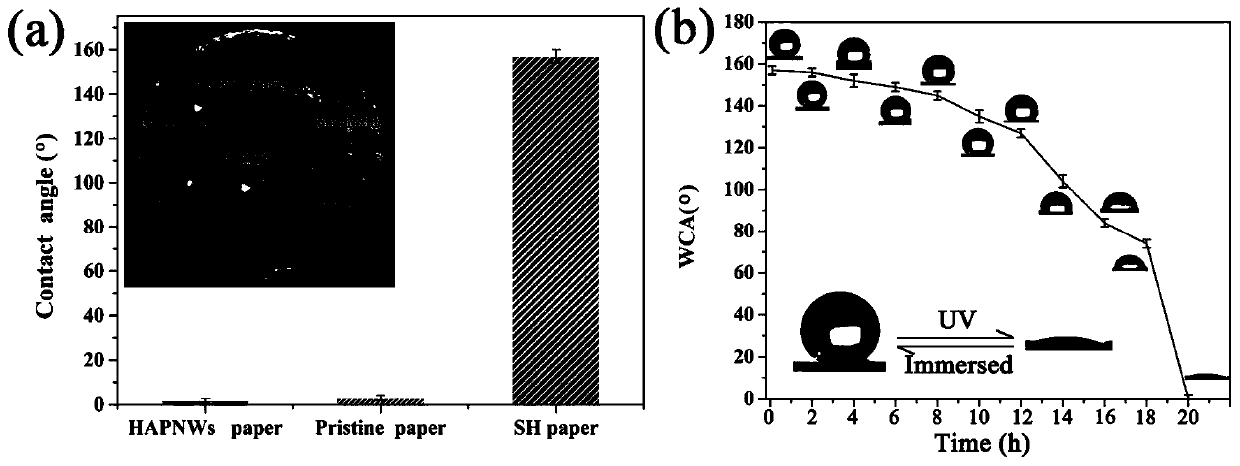

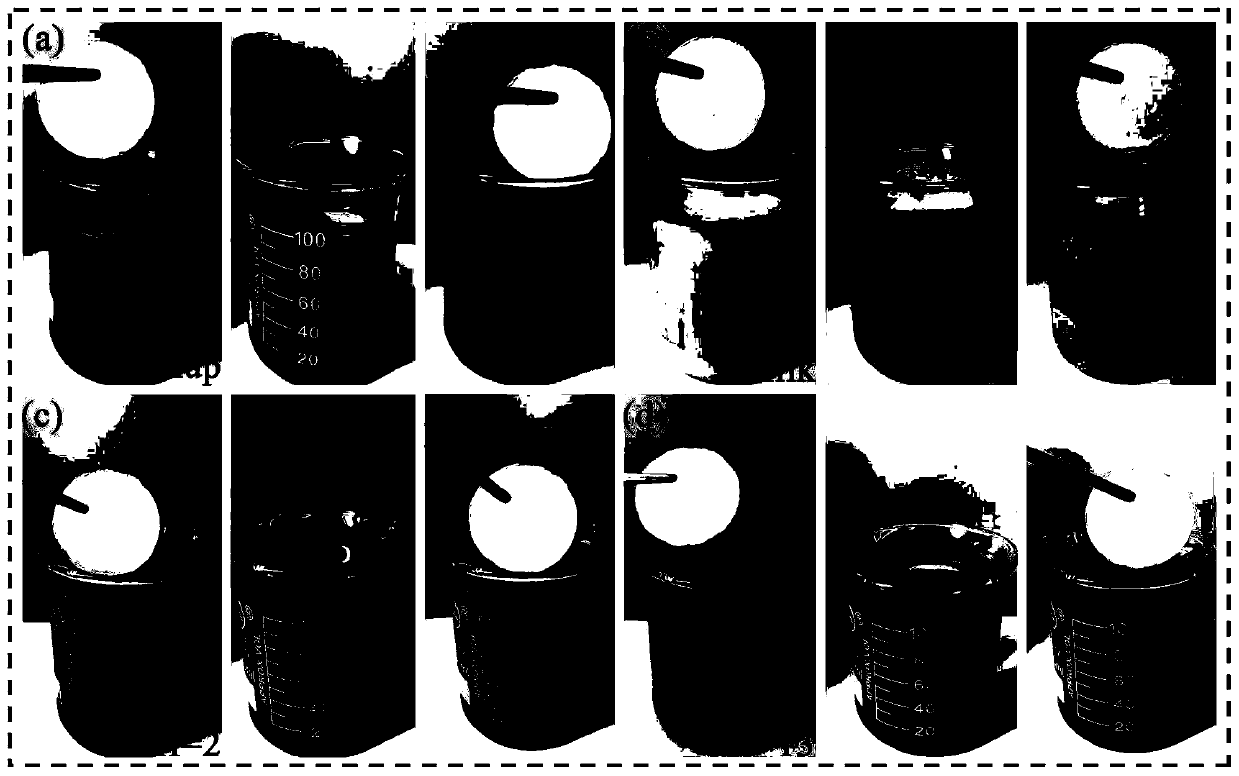

[0032] 3. Preparation of superhydrophobic paper sheet: 0.1 g of Kevlar fib...

Embodiment 2

[0035] 1. Preparation of ultra-long hydroxyapatite nanowires: Add calcium chloride (0.22, 10ml) and sodium hydroxide solution (0.7, 10ml) to a mixed solution of oleic acid (14ml), ethanol (14ml), and react for a period of time A certain amount of sodium dihydrogen phosphate solution (0.29g, 10ml) was added after a certain amount of time. Then transfer the obtained milky white reaction precursor into a high-temperature reaction kettle at 185° C. for 18 hours to obtain ultra-long hydroxyapatite nanowires.

[0036] 2. Preparation of nano-titanium dioxide: Mix 2ml of tetrabutyl titanate, 30ml of ethanol and 10ml of glycerin, stir at room temperature for 15min, then transfer to a high-temperature reactor at 190°C for 24h. The titanium dioxide nanoparticles obtained by the reaction are washed with ethanol and dried, and then baked at a high temperature of 435° C. for 2.5 hours to obtain flower-shaped titanium dioxide nanoparticles.

[0037] 3. Preparation of superhydrophobic paper ...

Embodiment 3

[0040]1. Preparation of ultra-long hydroxyapatite nanowires: adding calcium chloride (0.22, 10ml) and sodium hydroxide solution (0.7, 10ml) to a mixed solution of oleic acid (20ml) and ethanol (20ml) to react for a period of time Then add a certain amount of sodium dihydrogen phosphate solution (0.29g, 10ml). Then transfer the obtained milky white reaction precursor into a high-temperature reactor at 190° C. for 20 h to obtain ultra-long hydroxyapatite nanowires.

[0041] 2. Preparation of nano-titanium dioxide: Mix 2ml of tetrabutyl titanate, 30ml of ethanol and 10ml of glycerin, stir at room temperature for 15min, then transfer to a high-temperature reactor at 180°C for 22h. The titanium dioxide nanoparticles obtained by the reaction are washed with ethanol and dried, and then baked at a high temperature of 450° C. for 3 hours to obtain flower-shaped titanium dioxide nanoparticles.

[0042] 3. Preparation of superhydrophobic paper sheet: 0.1 g of Kevlar fiber washed with ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com