Aseptic filling apparatus for facial masks and mask production method thereof

A filling surface and equipment technology, applied in skin care preparations, medical preparations containing active ingredients, packaging, etc., can solve problems such as rupture, deformation and expansion of mask bags, eliminate hidden dangers, prolong shelf life, and improve safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

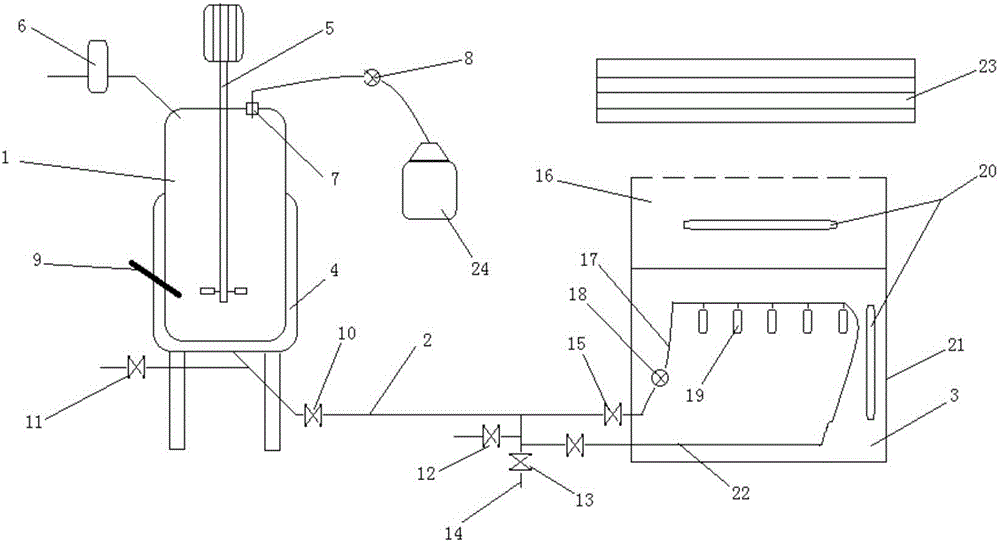

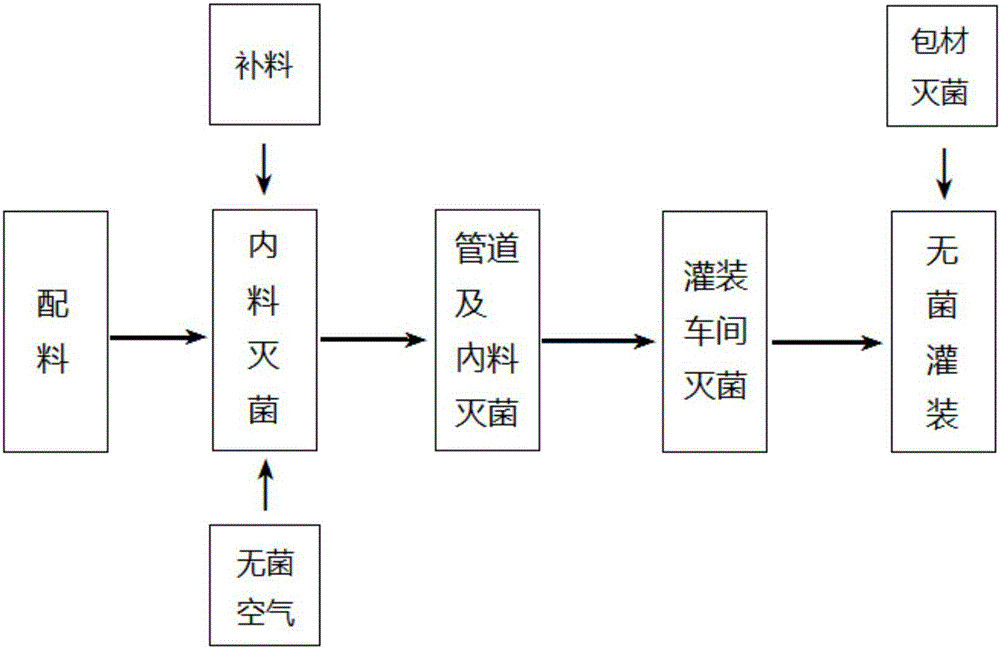

Method used

Image

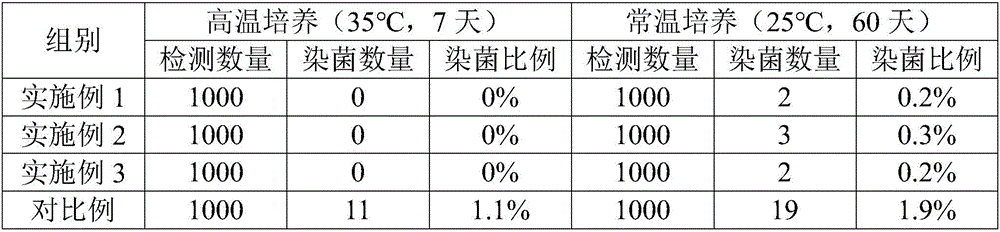

Examples

Embodiment 1

[0031] The mask prescription is: coenzyme Q10 0.01kg, olive oil 5kg, lipoic acid 0.1kg, nicotinamide 0.1kg, β-glucan 0.1kg, vitamin B6 0.1kg, vitamin C 1.0kg, vitamin B2 0.1kg, dipotassium glycyrrhizinate 0.1kg, citric acid 0.1kg, vitamin E 0.5kg, 1,2-propanediol 5.0kg, 1,3-butanediol 1.0kg, polyglutamic acid 3.0kg, hydroxyethyl cellulose 0.1kg, glycerol polymethyl Acrylate / 1,2-propanediol / PVM / MA copolymer 4.0kg, triethanolamine 0.1kg, sodium lactate 1.0kg, ethylhexylglycerin 0.1kg, add deionized water to 100kg.

[0032] The preparation method of the mask raw materials is as follows: take coenzyme Q10, add it to olive oil, and shake it for 30 minutes at 35°C to fully dissolve coenzyme Q10 in olive oil for later use; mix deionized water, 1,3-butanediol, Mix amino acid and hydroxyethyl cellulose, heat to 85°C, add coenzyme Q10 and olive oil after dissolving completely, then add triethanolamine, glycerol polymethacrylate / 1,2-propanediol / PVM / MA at 50°C Copolymer, sodium lactate, ...

Embodiment 2

[0034] The mask prescription is: Coenzyme Q10 0.05kg, olive oil 7.5kg, lipoic acid 0.25kg, nicotinamide 0.25kg, β-glucan 0.25kg, vitamin B 6 0.25kg, vitamin C 2kg, vitamin B 2 0.25kg, dipotassium glycyrrhizinate 0.25kg, citric acid 0.25kg, vitamin E 1.5kg, 1,2-propanediol 7.5kg, 1,3-butanediol 2.5kg, polyglutamic acid 4kg, hydroxyethyl cellulose 0.2kg, glycerol polymethacrylate / 1,2-propylene glycol / PVM / MA copolymer 6kg, triethanolamine 0.25kg, sodium lactate 2.5kg, ethylhexylglycerin 0.2kg, add deionized water to 100kg.

[0035] The preparation method of mask raw materials is as follows: take coenzyme Q10, add it to olive oil, and shake it for 30 minutes at 35°C to fully dissolve coenzyme Q10 in olive oil for later use; mix deionized water, 1,3-butanediol, Mix amino acid and hydroxyethyl cellulose, heat to 85°C, add coenzyme Q10 and olive oil after dissolving completely, then add triethanolamine, glycerol polymethacrylate / 1,2-propanediol / PVM / MA at 50°C Copolymer, sodium la...

Embodiment 3

[0037] Coenzyme Q10 0.1kg, olive oil 10kg, lipoic acid 0.5kg, niacinamide 0.5kg, β-glucan 0.5kg, vitamin B 6 0.5kg, vitamin C 3kg, vitamin B 2 0.5kg, dipotassium glycyrrhizinate 0.5kg, citric acid 0.5kg, vitamin E 2kg, 1,2-propanediol 10kg, 1,3-butanediol 5kg, polyglutamic acid 5kg, hydroxyethyl cellulose 0.3kg, Glycerin polymethacrylate / 1,2-propylene glycol / PVM / MA copolymer 8kg, triethanolamine 0.5kg, sodium lactate 3.5kg, ethylhexylglycerin 0.3kg, add deionized water to 100kg.

[0038] The preparation method of mask raw materials is as follows: take coenzyme Q10, add it to olive oil, and shake it for 30 minutes at 35°C to fully dissolve coenzyme Q10 in olive oil for later use; mix deionized water, 1,3-butanediol, Mix amino acid and hydroxyethyl cellulose, heat to 85°C, add coenzyme Q10, total olive oil after dissolving completely, then add triethanolamine, glycerol polymethacrylate / 1,2-propanediol / PVM / MA at 50°C Copolymer, sodium lactate, niacinamide, β-glucan, lipoic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com