A kind of inorganic superhydrophobic coating and its application

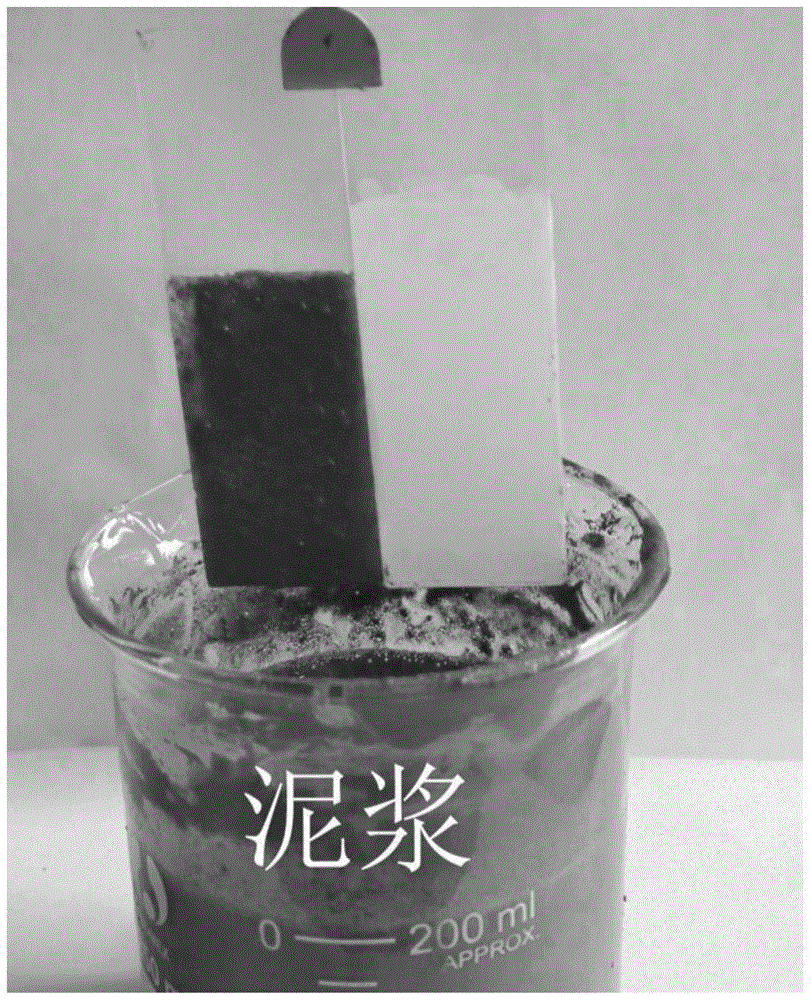

A super-hydrophobic coating and inorganic technology, applied in anti-fouling/underwater coatings, coatings, layered products, etc., can solve the problems of limited use and high cost, and achieve widened application range, excellent stability, and coatings. Efficient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of superhydrophobic coatings

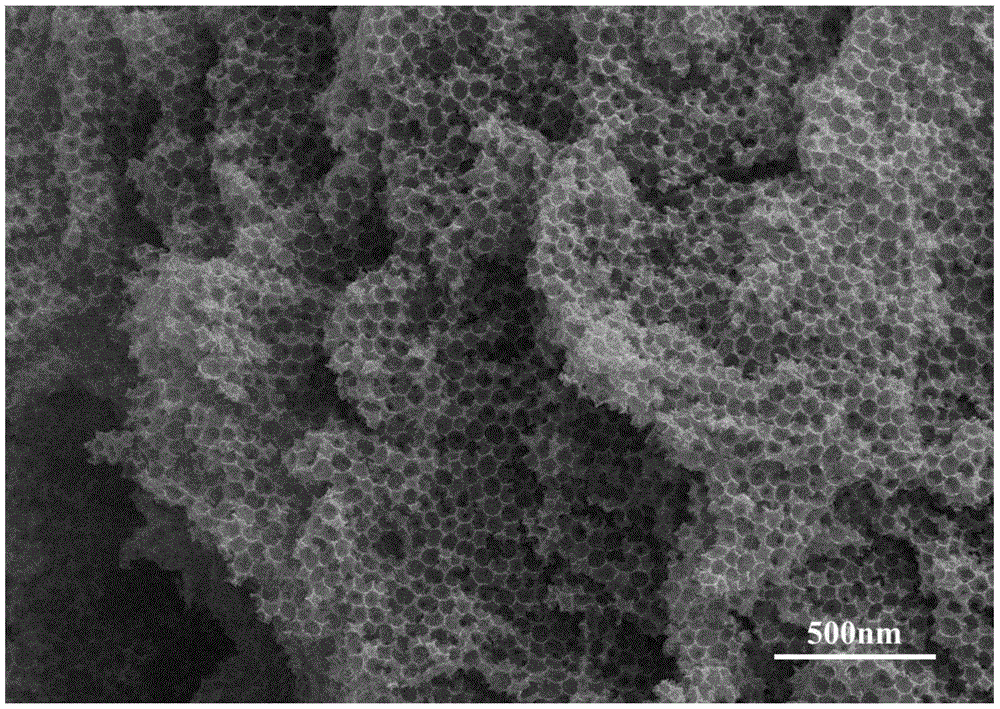

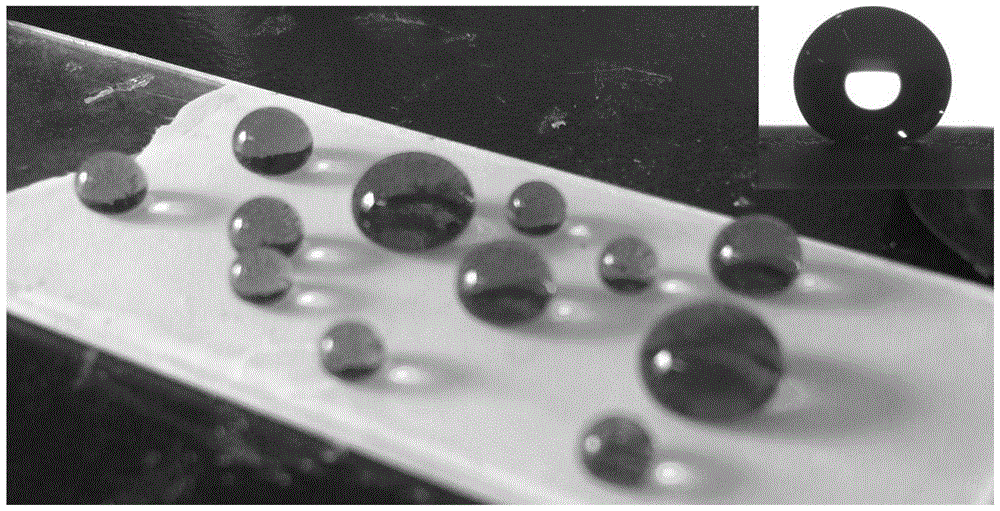

[0040] The silica sol was injected into the reactor equipped with 80nm polystyrene (PS) nanospheres prepared according to method three under negative pressure conditions, and the template was immersed for 2 hours, then the reactor was sealed and placed in a constant temperature box, and reacted at 60 ° C for 12 hours. 570°C temperature program removes the template to obtain a solid block micro-nano composite polyhedron, and the obtained block micro-nano composite polyhedron is fully ground to powder, and the particle size distribution range of the powder is 100nm-5000nm (Nano particle size and potential analyzer of British Malvern company Nano-ZS90 test, the following steps and implementation cases are the same); take 0.1g of micro-nano composite polyhedron powder into the reactor, then add 10.0mL (7.88g) of dispersion acetone, and add 20.6μL (0.30 g) Perfluorooctyltrimethoxysilane, the modification reaction was carried out...

Embodiment 2

[0049] (1) Preparation of superhydrophobic coatings

[0050] The silica sol was injected into the reactor equipped with 200nm polystyrene (PS) nanospheres prepared by method three under negative pressure conditions, and the template was immersed for 2 hours, then the reactor was sealed and placed in a constant temperature box, and reacted at 60°C for 12 hours. 570 ° C temperature program removed the template to obtain a solid block micro-nano composite polyhedron, the resulting block micro-nano composite polyhedron is fully ground to powder, take 0.1g of the micro-nano composite polyhedron powder into the reactor, and then add 10.0mL (7.88g ) dispersion liquid acetone, when the temperature of the system reaches 25°C, add 36.9 μL (0.57 g) of perfluorodecyltrimethoxysilane, and carry out the modification reaction for 12 hours. After the reaction, the mass fraction of the micro-nano composite polyhedron is controlled to be 2.7% by volatilization. That is, the superhydrophobic coa...

Embodiment 3

[0056] (1) Preparation of superhydrophobic coatings

[0057] The silica sol was injected into the reactor equipped with 300nm polyacrylamide (PAM) nanospheres prepared by method 1 under negative pressure conditions, and the template was immersed for 2 hours, then the reactor was sealed and placed in an incubator, and reacted at 60°C for 12 hours. Soak in water to remove the template to obtain a solid block micro-nano composite polyhedron, fully grind the obtained block micro-nano composite polyhedron to powder, take 0.1g of the micro-nano composite polyhedron powder into the reactor, and then add 10.0mL (7.88g) to disperse Liquid acetone, when the temperature of the system reaches 25°C, add 19.1 μL (0.22 g) trifluoropropane trimethoxysilane, carry out the modification reaction for 12 hours, and control the mass fraction of the micro-nano composite polyhedron to 5.0% by volatilization after the reaction is completed, which is prepared Superhydrophobic coatings;

[0058] The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com