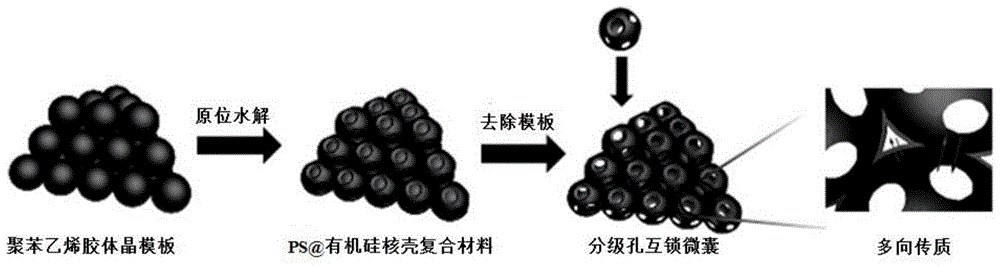

A kind of preparation method of organosilicon material graded pore structure interlocking microcapsules

A technology of organosilicon and graded pores, applied in the fields of inorganic, organic and polymer materials, can solve the problems of complex preparation process, and achieve the effect of simple and easy preparation process, mild reaction conditions and good industrial development prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Surface functionalization of polystyrene colloidal crystal templates

[0039] Submerge 1g of the dried 500nm polystyrene colloidal crystal template prepared according to method 2 in 40mL concentrated sulfuric acid (98% by mass fraction, the same as the concentrated sulfuric acid in the following steps and embodiments), and react at a constant temperature of 40°C for 4h. After the reaction, Discard the liquid, wash with water until the pH value of the supernatant is constant, and freeze-dry the resulting product (the freeze-drying temperature is below -50°C and the steps are the same as the freeze-drying in the embodiments) to obtain the sulfonic acid group on the surface. Polystyrene colloidal crystal template;

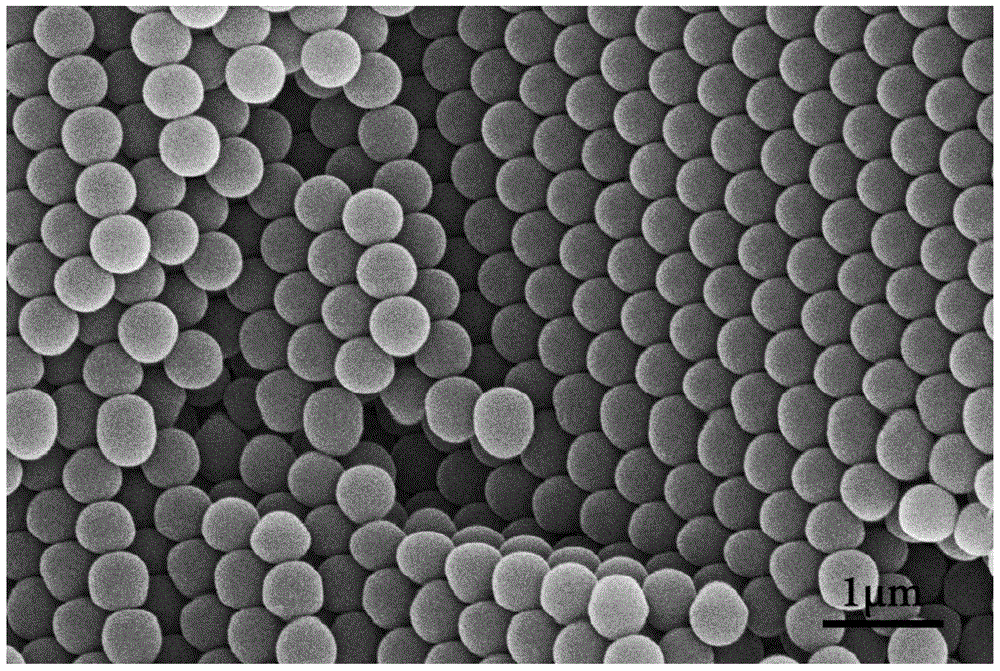

[0040] attached figure 2 It was obtained by scanning the polystyrene colloidal crystal template (according to method 2) with a FEI Nano SEM 450 electron scanning electron microscope. It can be seen from the figure that the structure of the polystyrene col...

Embodiment 2

[0047] (1) Surface functionalization of polystyrene (PS) colloidal crystal templates

[0048] Immerse 1 g of the dried polystyrene colloidal crystal template with a particle size of 200 nm prepared according to method 1 in 40 mL of concentrated sulfuric acid, and react at a constant temperature of 40 ° C for 3 h. After the reaction, discard the liquid and wash with water until the pH of the supernatant is lower After transformation, the resulting product is freeze-dried to obtain a polystyrene colloidal crystal template with sulfonic acid groups on the surface;

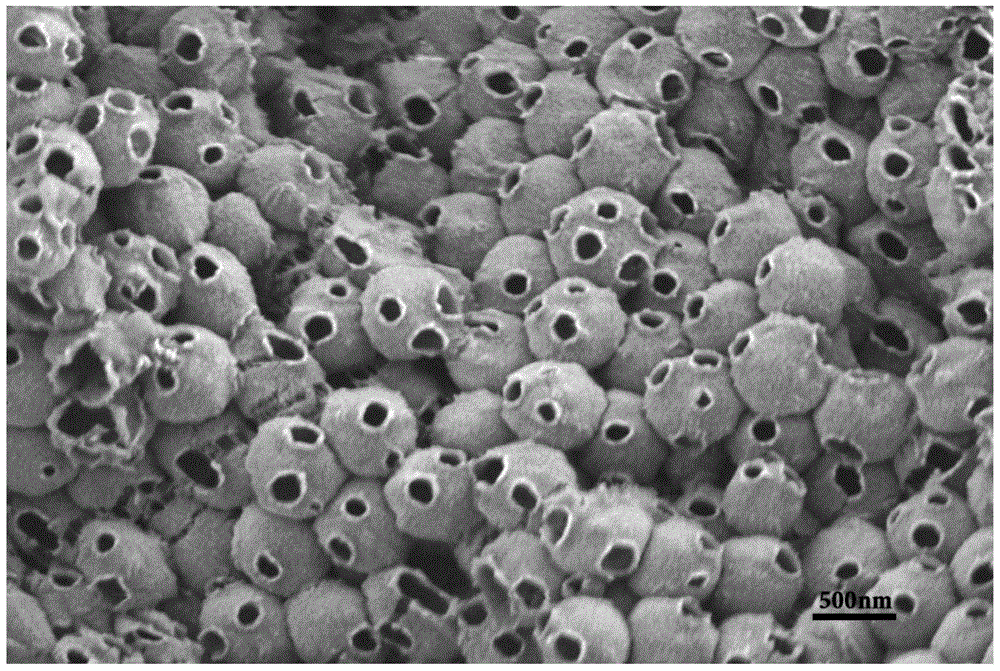

[0049] (2) Preparation of PS@organosilicon core-shell composites

[0050] 1 g of dry polystyrene colloidal crystal templates with sulfonic acid groups on the surface were placed in the reactor, and then 10 mL of absolute ethanol and 3 mL of 3-aminopropyltriethoxysilane (APTES ), soaked at room temperature (25°C) for 5h, added 10mL of water to the reaction system, reacted at room temperature for 24h, washed the obtain...

Embodiment 3

[0053] (1) Surface functionalization of polystyrene (PS) colloidal crystal templates

[0054] Submerge 1 g of the dried polystyrene colloidal crystal template with a particle size of 700 nm prepared according to method 3 in 40 mL of concentrated sulfuric acid, and react at a constant temperature of 50 ° C for 8 h. After the reaction, discard the liquid and wash with water until the pH of the supernatant is lower After transformation, the resulting product is freeze-dried to obtain a polystyrene colloidal crystal template with sulfonic acid groups on the surface;

[0055] (2) Preparation of PS@organosilicon core-shell composites

[0056] A dry 1g polystyrene colloidal crystal template with sulfonic acid groups on the surface was placed in the reactor, and then 10mL of absolute ethanol and 5.5mL of 3-aminopropyltriethoxysilane ( APTES), after soaking at room temperature (25°C) for 5h, adding 10mL of water to the reaction system, reacting at room temperature for 24h, washing the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com