A kind of preparation method and application of potassium octatitanate whisker

A technology of potassium octatitanate and whiskers, which is applied in the field of adsorbing heavy metal ions with potassium octatitanate, can solve the problems of complex production process of potassium octatitanate, restricted development and high cost, achieve good industrial development prospects and reduce production costs , the effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of potassium octatitanate reaction precursor

[0028] Using metatitanic acid and potassium carbonate as raw materials, potassium carbonate and metatitanic acid (containing TiO 2 , 40wt%) molar ratio [n(K 2 CO 3 ) / n(TiO 2 )] at a ratio of 1:4.5 and mix evenly at room temperature, put it in a drying oven at 150°C, stir regularly, dry for 24 hours to obtain a reaction precursor, and grind it finely for later use.

[0029] (2) Preparation of potassium octatitanate whiskers

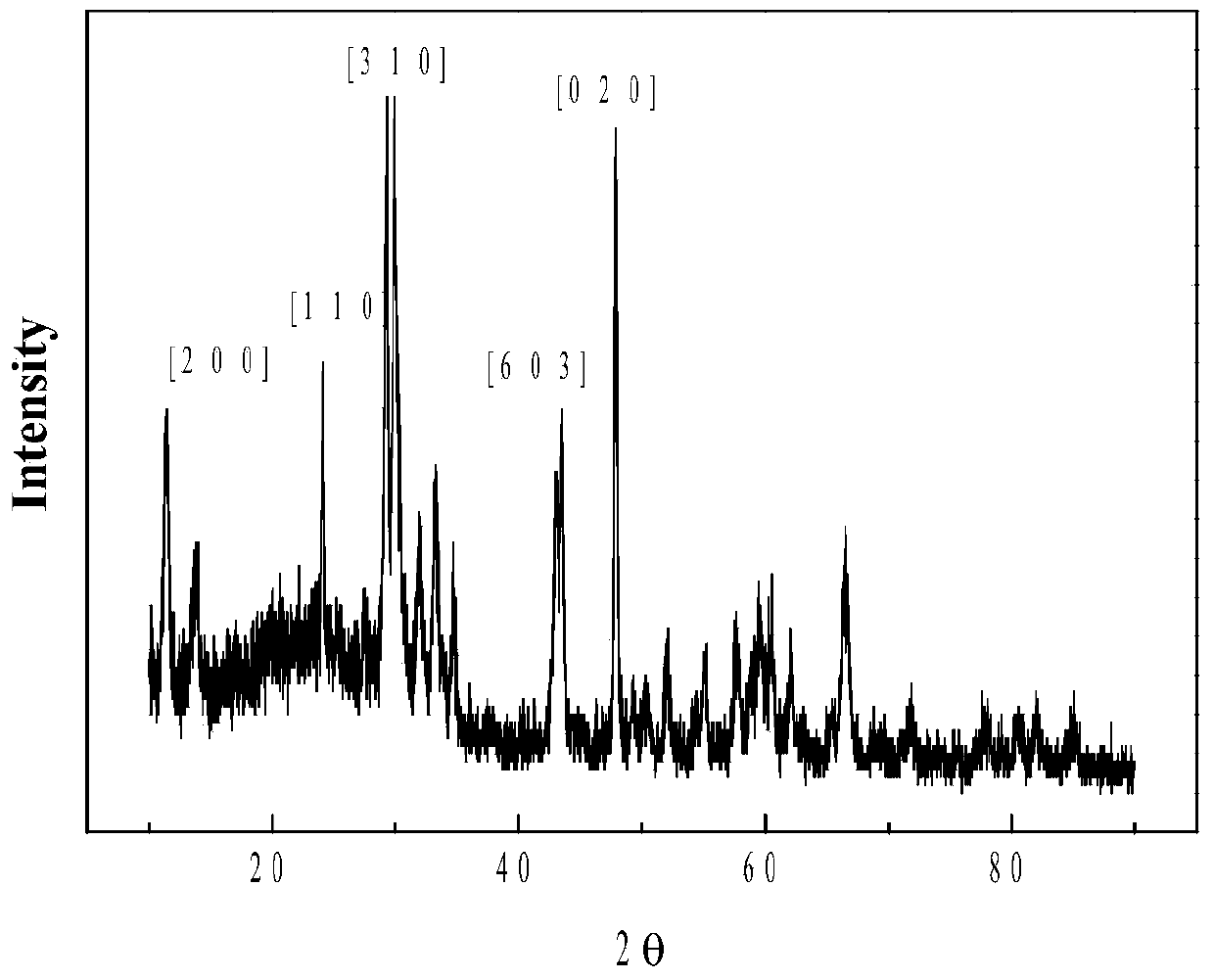

[0030] Take 100g of the obtained reaction precursor and put it into a 250ml crucible, put it in a muffle furnace, and use the method of gradient heating to roast (the heating program is: 200°C 1h+300°C 1h+400°C 1h+500°C 1h+600°C 8h ). Put the sample obtained after roasting into an azeotropic water bath and boil for 10 hours. After the product is leached in water, it is filtered, washed and dried to obtain potassium octatitanate whiskers. figure 1 TiO in potassium carbonate and meta...

Embodiment 2

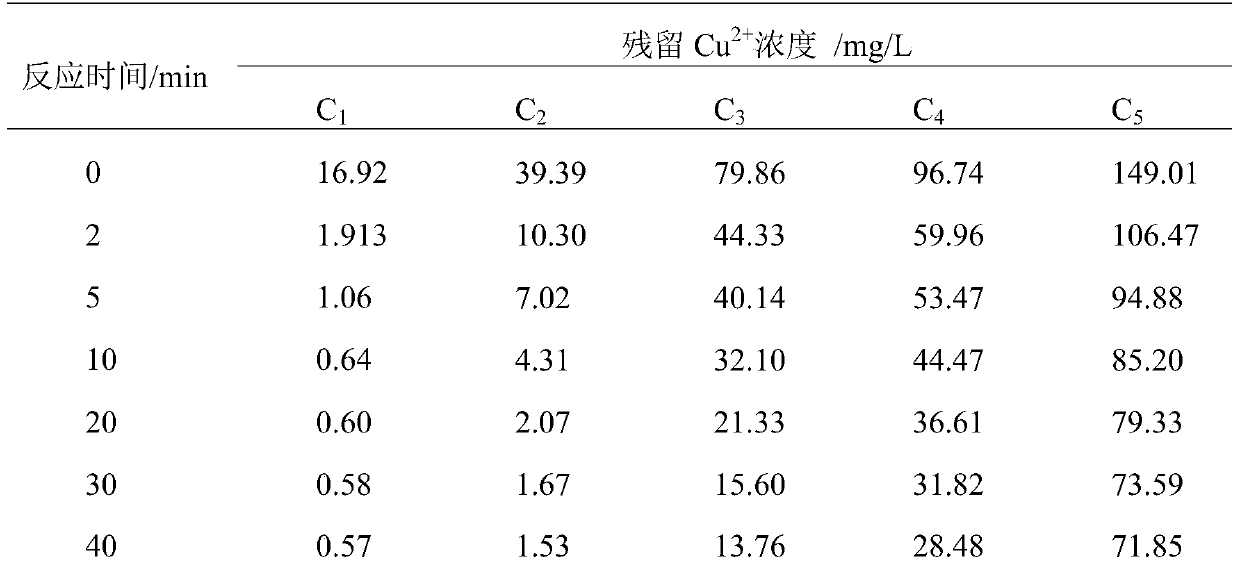

[0044] Potassium octatitanate whiskers are prepared by the same method as in Implementation 1, and the experimental steps for the absorption of heavy metal ions by potassium octatitanate whiskers are the same as in Example 1, changing the ion solution to 80, 120, 160, 200, 300 mg / L of Pb 2+ solution, potassium octatitanate whiskers can be obtained for different concentrations of Pb 2+ Adsorption effect, as shown in Table 3:

[0045] Table 3 Potassium octatitanate whiskers to different concentrations of Pb 2+ Adsorption

[0046]

[0047]

[0048] Note: C 1 Indicates Pb 2+ The initial concentration is 80mg / L; C 2 Indicates Pb 2+ The initial concentration is 120mg / L; C 3 Indicates Pb 2+ The initial concentration is 160mg / L; C 4 Indicates Pb 2+ The initial concentration is 200mg / L; C 5 Indicates Pb 2+ The initial concentration is 300mg / L.

[0049] After 120min of reaction, potassium octatitanate whiskers reacted with different concentrations of Pb 2+ The adsorpt...

Embodiment 3

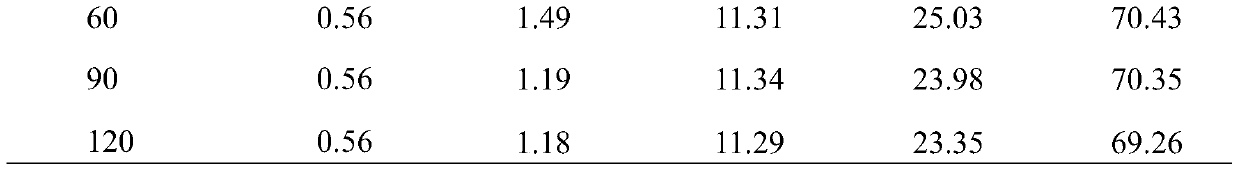

[0055] Potassium octatitanate whiskers were prepared by the same method as in Implementation 1. The experimental procedure for the adsorption of heavy metal ions by potassium octatitanate whiskers was the same as that in Example 1. The amount of potassium octatitanate whiskers was changed to 1.0 g, and the ion solution was changed to 40, 80, 120, 160, 200mg / L Ni 2+ solution, potassium octatitanate whiskers can be obtained for different concentrations of Ni 2+ Adsorption effect, as shown in Table 5:

[0056] Table 5 Potassium octatitanate whiskers to different concentrations of Ni 2+ Adsorption

[0057]

[0058]

[0059] Note: C 1 means Ni 2+ The initial concentration is 40mg / L; C 2 means Ni 2+ The initial concentration is 80mg / L; C 3 means Ni 2+ The initial concentration is 120mg / L; C 4 means Ni 2+ The initial concentration is 160mg / L; C 5 means Ni 2+ The initial concentration is 200mg / L.

[0060] After 120min of reaction, potassium octatitanate whiskers rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com