Method for preparing SAPO-35 molecular sieve with N-methyl piperidine being template agent

A technology of SAPO-35 and methylpiperidine, which is applied in the field of preparing SAPO-35 molecular sieves, can solve the problems of long crystallization time and narrow silicon content of SAPO-35, and achieve good crystallinity, good thermal stability and hydrothermal The effect of stability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

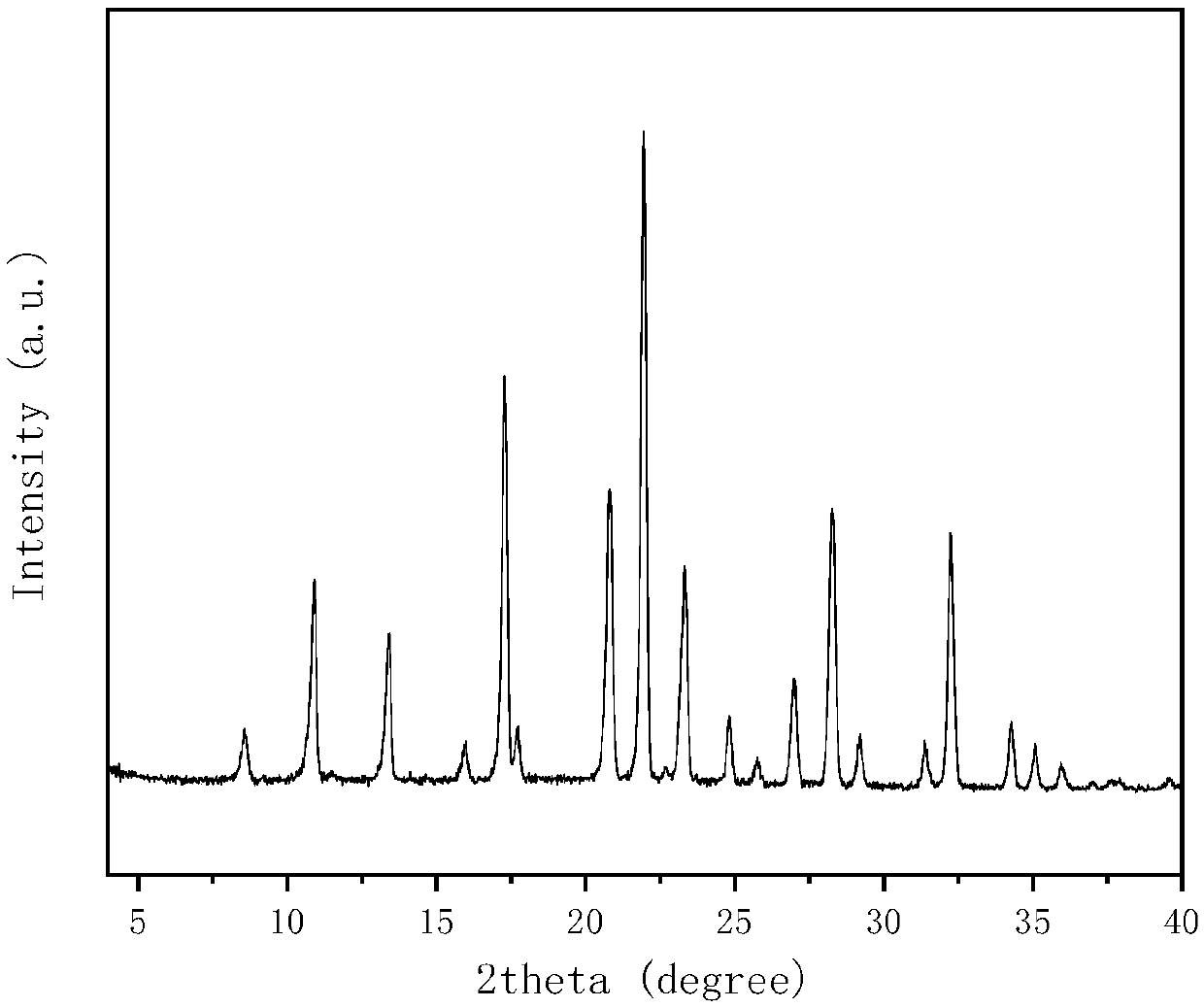

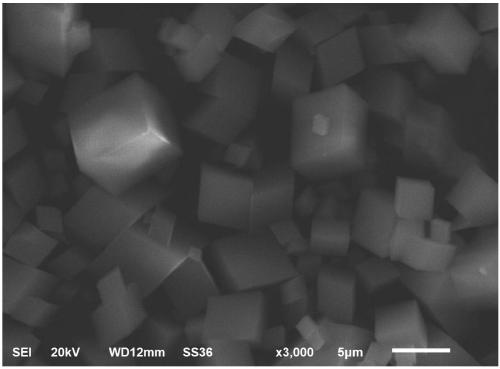

Embodiment 1

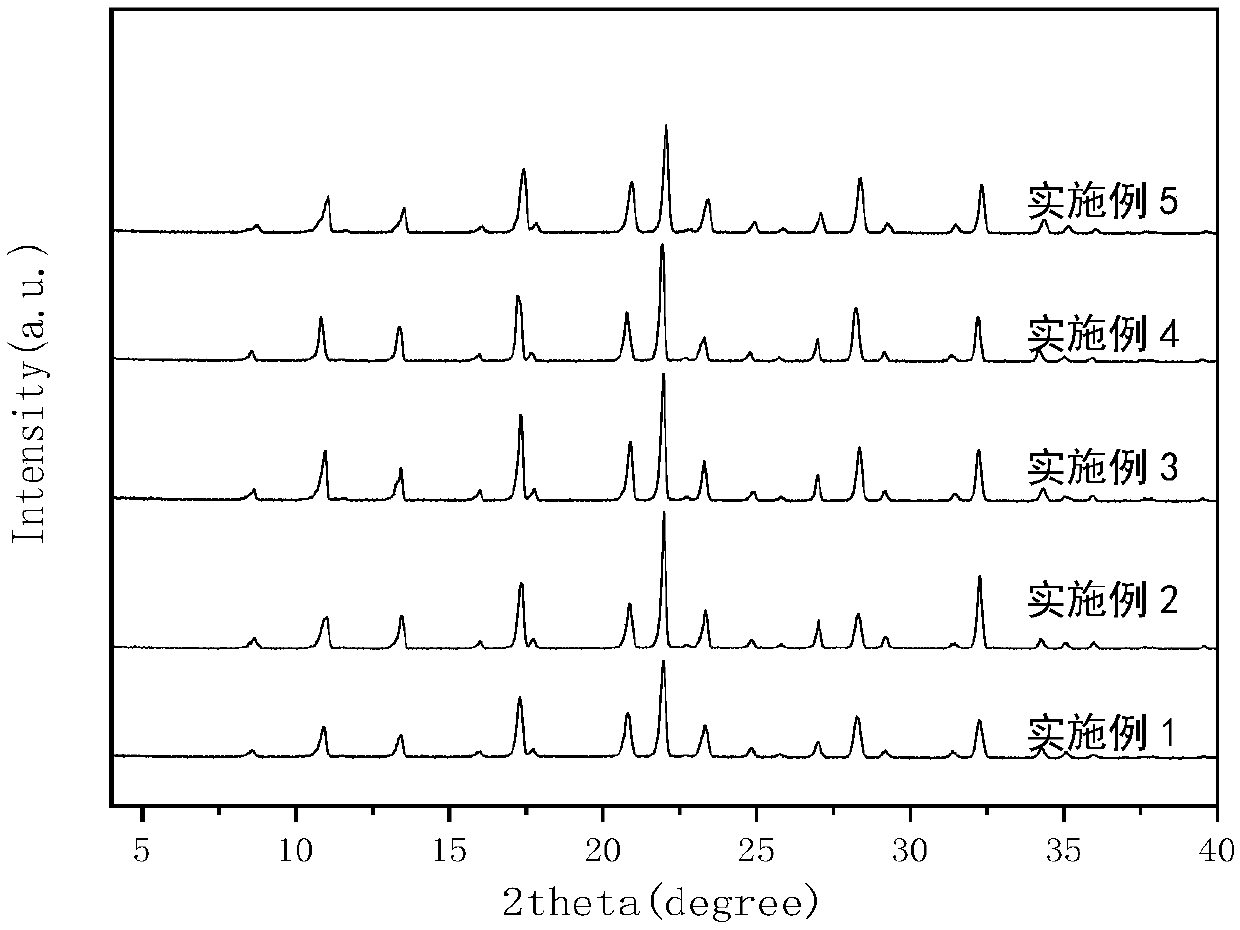

[0025] At 25°C, dissolve 1g of pseudo-boehmite with 16mL of deionized water, then dropwise add 3.3g of phosphoric acid (85% by mass) and continue stirring evenly, then add 0.31g of tetraethyl orthosilicate, 5.4mL of N -Methyl piperidine, stir evenly, transfer to a stainless steel reaction kettle, put it in an oven at 180°C for 3 days to crystallize, then cool the reaction kettle, collect the product, wash with deionized water until neutral, centrifuge, and dry at 75°C , the acquired product SAPO-35 molecular sieve, the product quality is 0.65g. In this example, the molar ratio of the synthesized gel is 6.15R:0.2SiO 2 :Al 2 o 3 : 2.0P 2 o 5 : 124H 2 O.

Embodiment 2

[0027] At 25°C, dissolve 1g of pseudo-boehmite with 16mL of deionized water, then dropwise add 3.3g of phosphoric acid (85% mass fraction) and continue to stir evenly, then add 0.62g of tetraethyl orthosilicate, 5.4mL of N -Methyl piperidine, stir evenly, transfer to a stainless steel reaction kettle, put it in an oven at 180°C for 3 days to crystallize, then cool the reaction kettle, collect the product, wash with deionized water until neutral, centrifuge, and dry at 75°C , the obtained product SAPO-35 molecular sieve, the product quality is 1.4g. In this example, the molar ratio of the synthesized gel is 6.15R:0.4SiO 2 :Al 2 o 3 : 2.0P 2 o 5 : 124H 2 O.

Embodiment 3

[0029] At 25°C, dissolve 1g of pseudo-boehmite with 16mL of deionized water, then dropwise add 3.3g of phosphoric acid (mass fraction 85%) and continue stirring evenly, then add 0.93g of tetraethyl orthosilicate, 5.4mL of N -Methyl piperidine, stir evenly, transfer to a stainless steel reaction kettle, put it in an oven at 180°C for 3 days to crystallize, then cool the reaction kettle, collect the product, wash with deionized water until neutral, centrifuge, and dry at 75°C , the obtained product SAPO-35 molecular sieve, the product quality is 1.4g. In this example, the molar ratio of the synthesized gel is 6.15R:0.6SiO 2 :Al 2 o 3 : 2.0P 2 o 5 : 124H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com