Bioreactor based on enzymatic-photocatalytic synergistic effect as well as preparation method and application of bioreactor in degradation of organic dye

A bioreactor, synergistic effect technology, applied in the application field of degrading organic dyes, can solve the problems of limited catalytic efficiency and narrow response range, and achieve the effect of improving catalytic efficiency, strong environmental adaptability and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

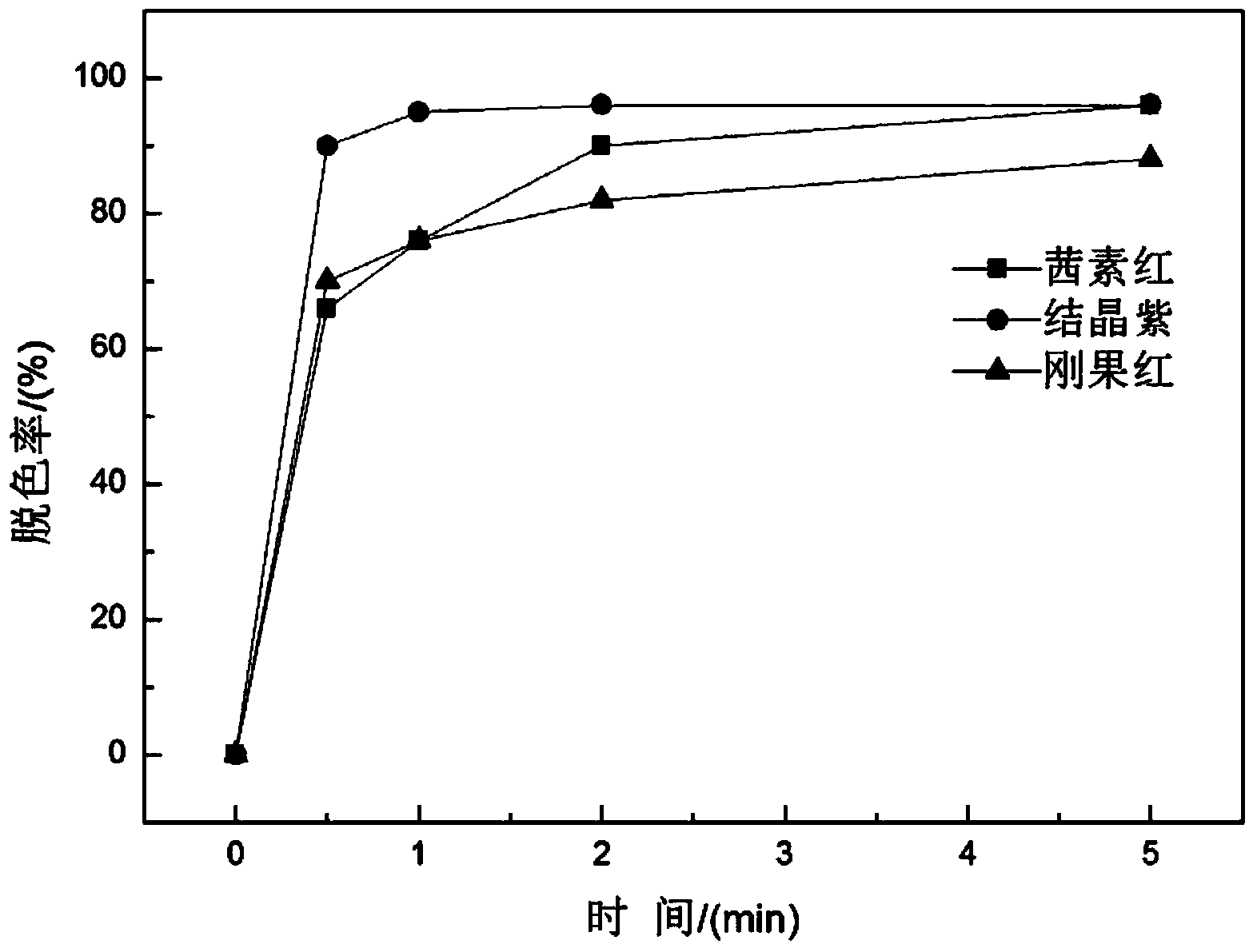

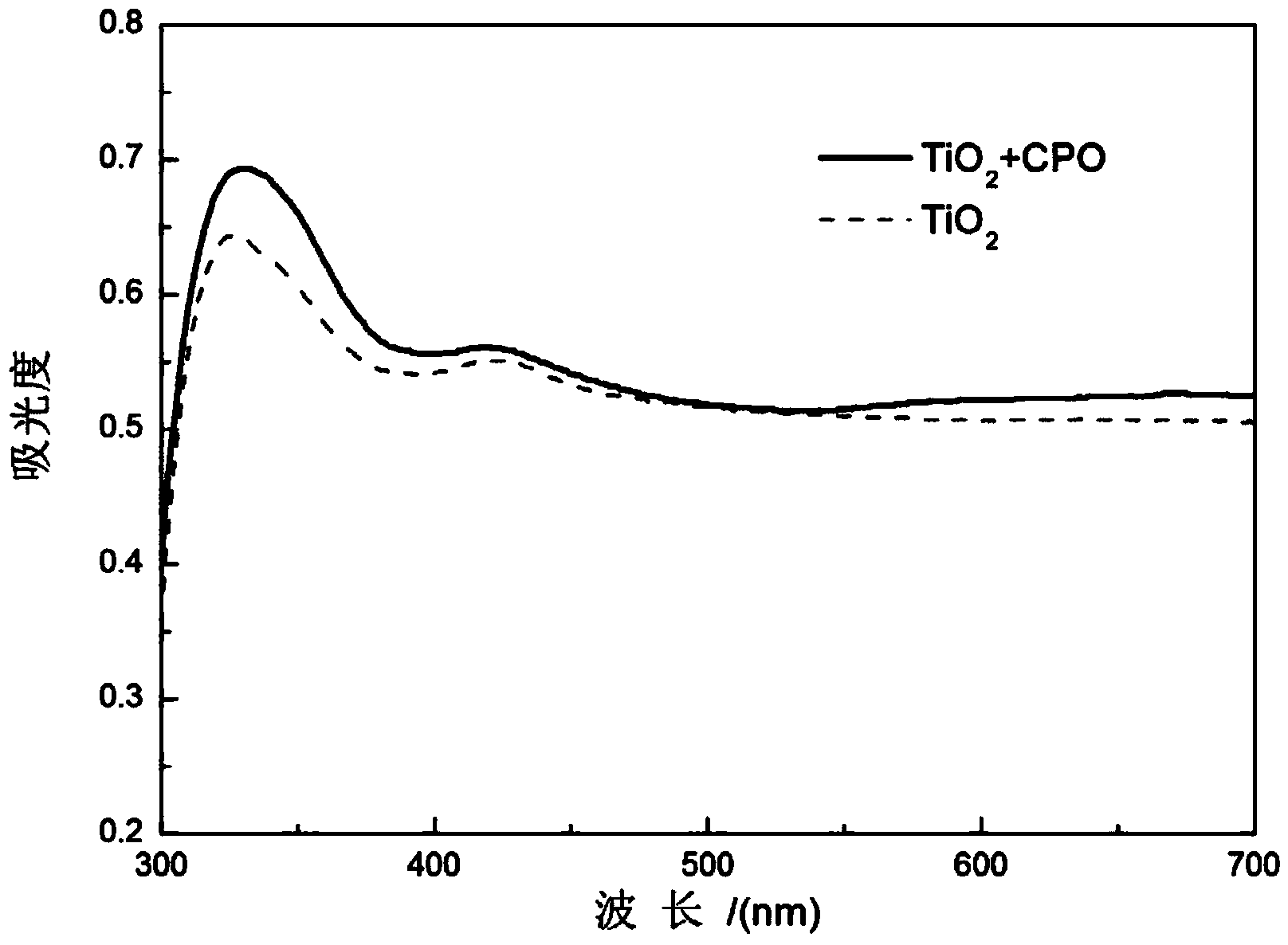

[0025] The organic dye degradation bioreactor of the present invention is based on the enzymatic-photocatalytic synergistic effect of chloroperoxidase-loaded TiO 2 Thin film, its preparation method and the method for organic dye degradation comprise the following steps:

[0026] (1) Analytical pure butyl titanate Ti(OC 4 h 9 ) 4 with ethanol C 2 h 5 OH is fully mixed according to the volume ratio of 1: (1~5), slowly add 1mol / L dilute HCl dropwise, adjust the pH value of the mixed solution to 2.0~8.0, stir magnetically at room temperature for 1~4h, and obtain a light yellow transparent sol A. Sol A was aged at room temperature for 12-24 hours to obtain gel B, namely TiO 2 Gel; aging makes the macromolecular structure in gel B more uniform, which is conducive to subsequent film formation;

[0027](2) Take the glass substrate and immerse it in analytically pure anhydrous ethanol and ultrasonically clean it for 10-15 minutes, then immerse it in analytically pure acetone and ...

Embodiment 1

[0037] (1) Analytical pure butyl titanate Ti(OC 4 h 9 ) 4 with ethanol C 2 h 5 OH was fully mixed according to the volume ratio of 1:1, and 1mol / L dilute HCl was slowly added dropwise to adjust the pH value of the mixed solution to 2.0, and magnetically stirred at room temperature for 2 hours to obtain light yellow transparent sol A, which was left to stand at room temperature After 24h, gel B was obtained;

[0038] (2) Take the glass substrate and immerse it in analytically pure absolute ethanol and ultrasonically clean it for 10 minutes, then immerse it in analytically pure acetone and ultrasonically clean it for 15 minutes, finally rinse it with deionized water, and dry it with nitrogen gas for later use;

[0039] (3) Coating by dipping-pulling method, immersing the cleaned glass substrate in gel B and standing for 10s, pulling the coating vertically and uniformly at a pulling speed of 2cm / min, and immediately putting it in an oven at 40°C dried to obtain TiO on a glas...

Embodiment 2

[0044] (1) Analytical pure butyl titanate Ti(OC 4 h 9 ) 4 with ethanol C 2 h 5 OH was fully mixed according to the volume ratio of 1:3, and 1mol / L dilute HCl was slowly added dropwise to adjust the pH value of the mixed solution to 4.0, and magnetically stirred at room temperature for 4 hours to obtain light yellow transparent sol A, which was left to stand at room temperature After 12h, gel B was obtained;

[0045] (2) Take the glass substrate and immerse it in analytically pure absolute ethanol and ultrasonically clean it for 10 minutes, then immerse it in analytically pure acetone and ultrasonically clean it for 15 minutes, finally rinse it with deionized water, and dry it with nitrogen gas for later use;

[0046] (3) Coating by dipping-pulling method, immersing the cleaned glass substrate in gel B and standing for 10s, pulling the coating vertically and uniformly at a pulling speed of 2cm / min, and immediately putting it in an oven at 25°C dried to obtain TiO on a glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com