Recombinant expression vector, genetically engineered bacterium, and culture method and application of genetically engineered bacterium

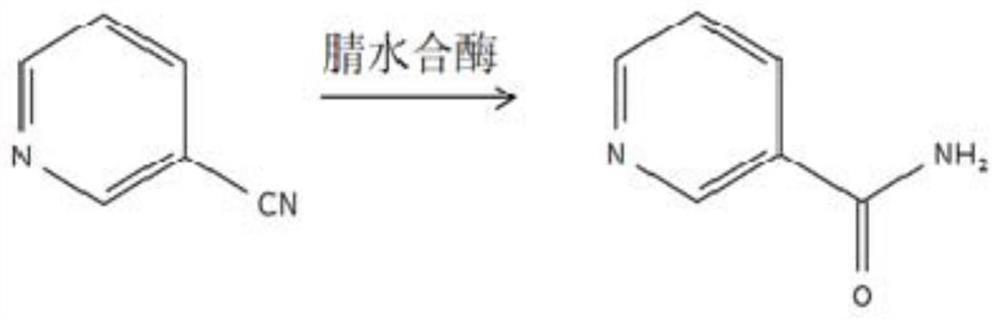

A technology of genetically engineered bacteria and expression vectors, which is applied in the field of genetically engineered bacteria and bacterial cultivation, and recombinant expression vectors, can solve the problems of low substrate tolerance, poor stability, and poor practicability, and achieve low production costs and excellent preparation conditions. Mild, pollution-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

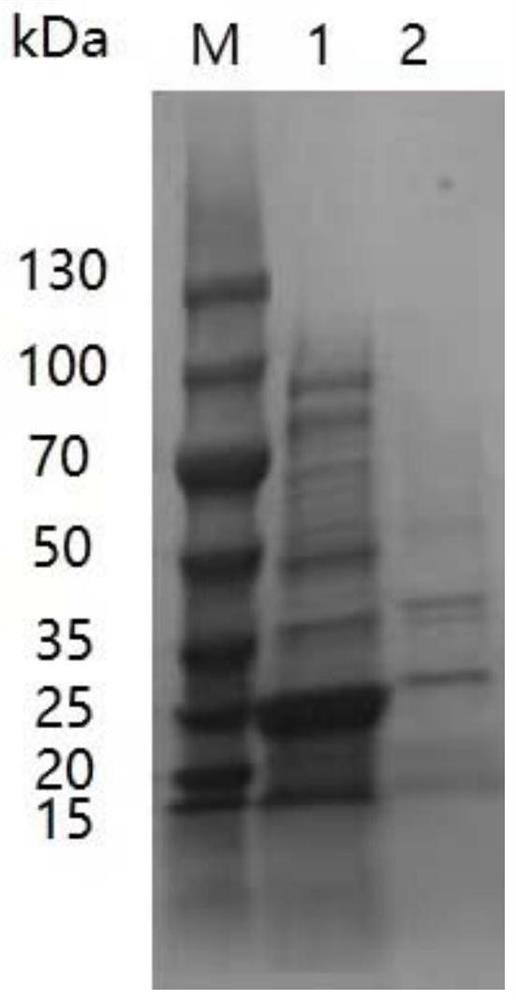

[0040] The recombinant plasmid pET24A (+) - NHTABC was synthesized from all gene, then converted to E. coli DH5α, selecting a positive clone, and obtain a large number of recombinant plasmid PETs 44A (+) - NHTABC, which contains a nitrile hydrated enzyme. Gene, the nitrile hydr enzyme gene sequence is SEQ ID NO.1.

[0041] 100 μl of E.Coli BL21 (DE3) perfosure cells were placed in a pre-cooled sterilized EP tube, and the ice is opened, and the cells are evenly suspended. Add 10 μL recombinant plasmid PET24A (+) - NHTABC, gently mix, ice bath for 30 min, and open the thermostat preheating. The EP tube was transferred to a dry thermostat of 42 ° C and then transferred to an ice bath and allowed cells to cool for 15 min. 900 μl of LB liquid medium containing non-antibiotics was added, and oscillated at 37 ° C, 250 rpm was oscillated for 1 h. Then, the 400ul bacteria was applied to the antibiotic LB agar plate. When there was no liquid flow in the surface of the gel, it was inverted i...

Embodiment 2

[0043] Seed Liquid Culture: Seeds from the transformed single bacteria in the plate inoculated to a shake flask containing 30 ml of seed liquid medium (containing kanamycin 50 μg / mL), TB medium, oscillated at 37 ° C, 200 rpm, 12h . The seed liquid medium formulation is: trypsin 10g / L, yeast extract 10 g / L and NaCl 5 g / L, the initial pH is 7.0.

[0044] Shake flask fermentation: The cultured seed fluid was inoculated into fermentation medium containing kanamycin (50 μg / ml) in a fermentation medium containing 1%, and added a final concentration of 0.6 mm. IPTG was added after 37 ° C, 200 rpm The final concentration was 0.1 g / L Cobalt chloride, and then induced at 22 ° C for 12 h, and the final OD was determined. 600 . The culture solution was centrifted and the cell precipitate was washed twice with physiological saline to give a wet bacterium. The formulation of fermentation medium is: trypsin 16 g / L, yeast extract 10 g / l, NaCl 5 g / L, lactose 10 g / L, the initial...

Embodiment 3

[0049] Seed Liquid Culture: Seeds from the transformed single bacteria in the plate inoculated to a shake flask containing 30 ml of seed liquid medium (containing kanamycin 50 μg / mL), TB medium, oscillated at 37 ° C, 200 rpm, 12h . The seed liquid medium formulation is: trypsin 10g / L, yeast extract 10 g / L, NaCl 5g / L, initial pH of 7.0.

[0050] Shake flask fermentation: The cultured seed fluid was inoculated into fermentation medium containing kanamycin (50 μg / ml) in a fermentation medium containing 1%, and added a final concentration of 0.6 mm. IPTG was added after 37 ° C, 200 rpm The final concentration was 0.1 g / L Cobalt chloride, and then induced at 28 ° C for 12 h, and the final OD was measured. 600 . The culture solution was centrifted and the cell precipitate was washed twice with physiological saline to give a wet bacterium. The formulation of fermentation medium is: trypsin 16 g / L, yeast extract 10 g / l, NaCl 5 g / L, lactose 10 g / L, the initial pH of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com