Method for testing particle packing density of concrete used powder

A technology of particle accumulation and testing method, applied in the field of particle accumulation density test, can solve the problems of inappropriate particle gradation, large accumulation volume of dry powder, disorderly arrangement, etc., and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

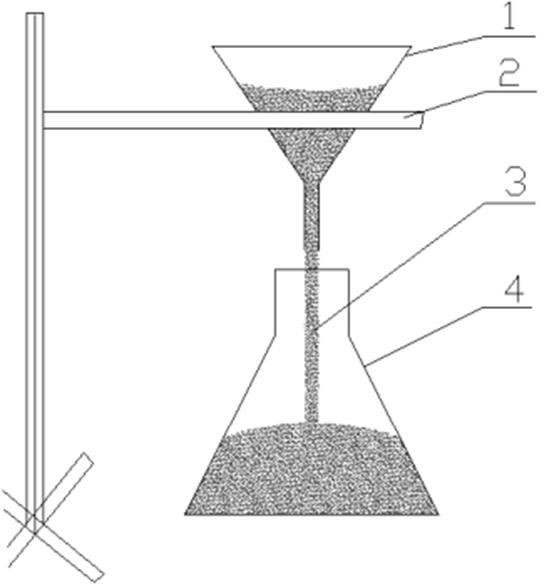

Image

Examples

Embodiment 1

[0041] Weigh the powder with a total mass of 1200g according to the following ratio (mass ratio), mix it evenly, and prepare cement paste:

[0042] a cement : microbeads : limestone powder : silica fume = 3 : 3 : 3.5 : 0.5

[0043] b cement : microbeads : limestone powder : silica fume = 7 : 1 : 1.5 : 0.5

[0044] The water-to-cement ratio σ is 0.15, and the superplasticizer is polycarboxylate high-efficiency superplasticizer (solid content 20.2%), with a dosage of 20g; defoamer (siloxane) 0.016g; retarder (sodium gluconate ) 0.6g; the test ambient temperature is 20°C. It can be calculated that the ratio of the dry powder mass in the slurry a and b to the total mass of the slurry is:

[0045] λ=1200 / (1200+1200×0.15+20+0.016+0.6)= 0.856766.

[0046] A large number of tests have shown that when the above additives are added, the initial setting time of the slurry is greater than 18 hours.

[0047] According to the national standard GB / T 208-94, the measured density of each pow...

Embodiment 2

[0063] Following test is carried out according to the method in embodiment 1:

[0064] Weigh the powder with a total mass of 1200g according to the following ratio, mix it evenly, and prepare cement paste:

[0065] A cement : fly ash = 5 : 5

[0066] B cement : mineral powder : fly ash = 5 : 2 : 3

[0067] C cement : microbeads : silica fume = 5 : 4 : 1

[0068] D cement : microbeads : limestone powder : silica fume = 3 : 3 : 3.5 : 0.5

[0069] E cement : microbeads : limestone powder : silica fume = 7 : 1 : 1.5 : 0.5

[0070] The water-to-cement ratio σ is 0.20, the superplasticizer is polycarboxylate high-efficiency superplasticizer (20.2% solid content), and the dosage is 16g; defoamer (siloxane) 0.016g; retarder (sodium gluconate ) 0.48g; the test environment temperature is 20°C. A large number of tests have shown that when the above additives are added, the initial setting time of the slurry is greater than 18 hours.

[0071] Table 2 lists the V of components from A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com