A magnetic surface-enhanced Raman spectroscopy substrate and a preparing method thereof

A surface-enhanced Raman and substrate technology, which is applied in the field of analysis and detection, can solve problems such as cumbersome operation, waste of energy, and impact on detection results, and achieve the effects of good dispersion, simple method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

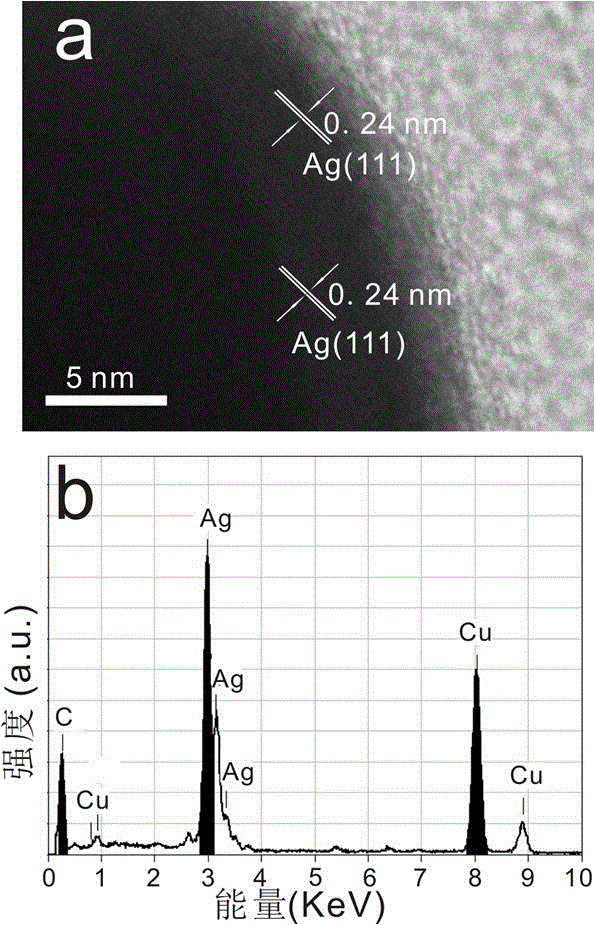

[0022] A magnetic surface-enhanced Raman spectroscopy substrate, the substrate is made of Fe 3 o 4 Core-shell structure Fe as the core and Ag as the shell 3 o 4 / Ag particles are piled up. The preparation method of the surface-enhanced Raman spectrum substrate with magnetic properties is as follows: Fe 3 o 4 Disperse the microspheres in water and ultrasonically disperse for 10-20 minutes to make a dispersion liquid; add ascorbic acid to the dispersion liquid, and the concentration of ascorbic acid in the dispersion liquid is 0.04-1.1g / L; then add AgNO to the dispersion liquid 3 , AgNO 3 The concentration in the dispersion liquid is 0.017-0.34g / L, react at 0-65°C for 20-120min, collect the product with a magnet after the reaction, wash with water and ethanol to obtain Fe 3 o 4 Surface-enhanced Raman spectroscopy substrate formed by stacking Ag particles.

Embodiment 2

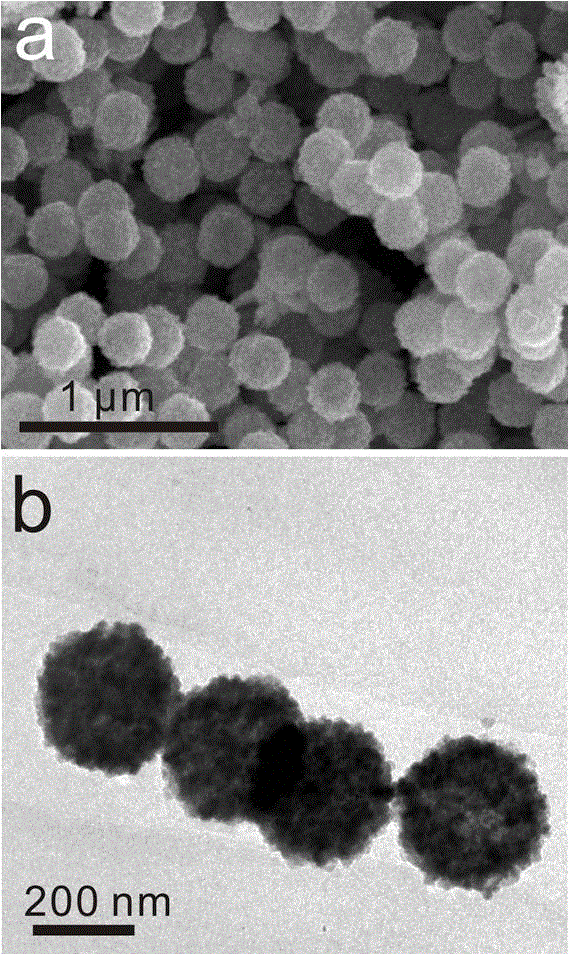

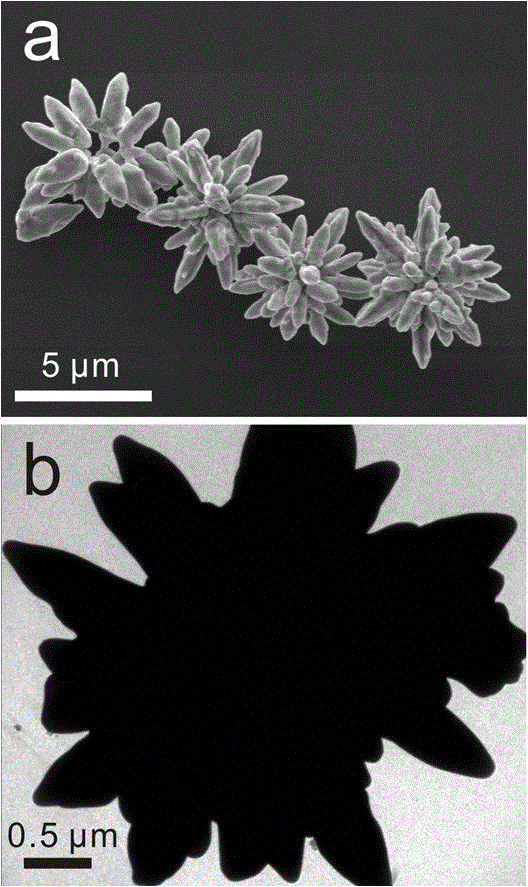

[0024] Dissolve 0.54g of ferric chloride hexahydrate, 1.176g of sodium citrate dihydrate, and 0.36g of urea in 40ml of distilled water, then add 0.3g of polyacrylamide and stir until completely dissolved; Put it in a 50mL reaction kettle of tetrafluoroethylene, seal it and place it in a blast drying oven, and react at 200°C for 7 to 10 hours; after the reaction is completed, cool it down to room temperature naturally, collect the black precipitate with a magnet, wash it with distilled water for 3 times, and then Washed three times with absolute ethanol, dried in a vacuum oven at 60° C. for 8 hours to obtain a black powder. Then take a small amount of black powder, add distilled water and ultrasonically disperse it, drop the dispersion onto a silicon wafer, and test it after natural drying to obtain the following: figure 1 The SEM picture shown in a shows that the obtained black powder is Fe with a diameter of about 200 nm 3 o 4 spherical particles. Fe 3 o 4 The dispersion...

Embodiment 3

[0028] The preparation method of the SERS substrate is the same as in Example 2, but the amount of the dispersion liquid added to 160 mL of distilled water is changed to 200 μL, and other conditions are the same as in Example 2. Such as Figure 4 As shown in a, when the amount of dispersion A added is 200 μL, Fe 3 o 4 / Ag particles are dispersed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com