Graphene-carbon graphite composite isostatic pressing material and preparation method thereof

A technology of graphene and carbon graphite, which is applied in the field of static pressure materials and its preparation, can solve the problems of low mechanical strength, physical and chemical properties that cannot meet high-end products, and low volume density of composite materials, and achieve high mechanical strength, excellent physical and chemical indicators, The effect of high volume density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

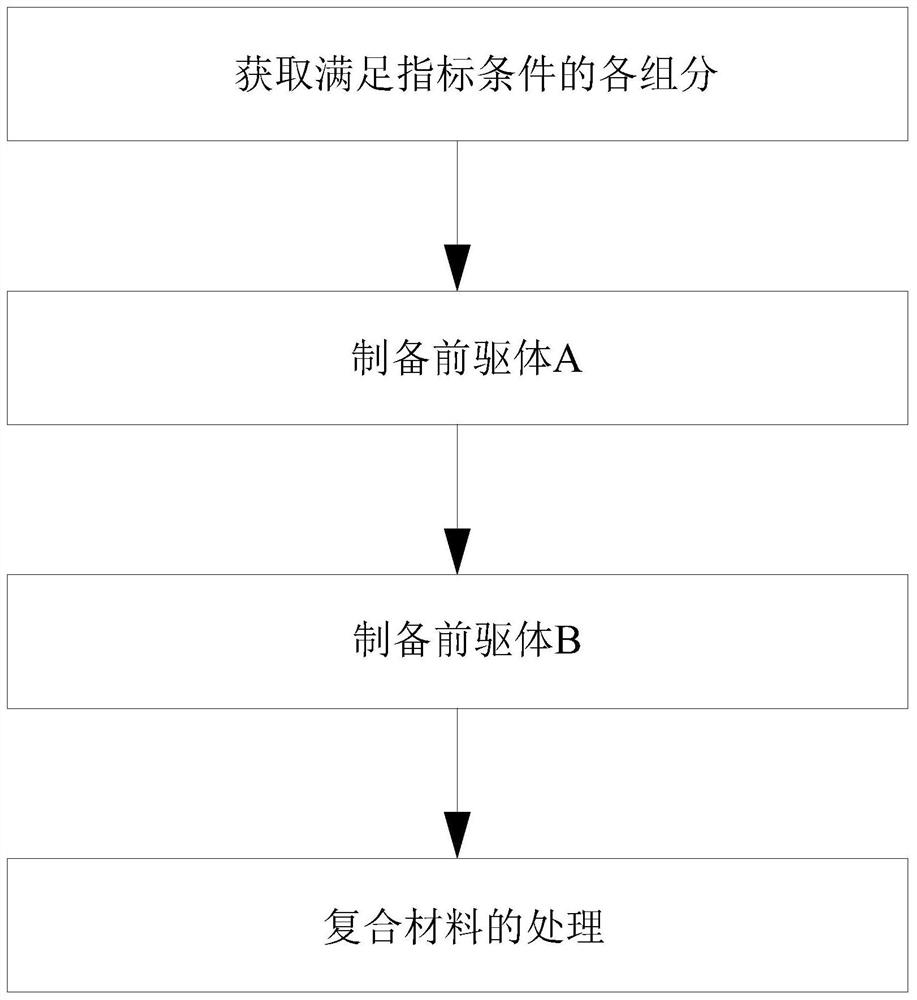

Method used

Image

Examples

Embodiment Construction

[0056] Based on the aforementioned background technology, the various physical and chemical properties of graphene composite materials currently produced cannot meet the technical requirements of high-end products, mainly manifested in technical defects such as low volume density and low mechanical strength of composite materials.

[0057] The inventors of the present application found that after adjusting the raw materials and proportions in the composite material, the particles of different particle sizes will be packed more tightly, and the bulk density, porosity, mechanical strength and thermal expansion coefficient of the material can reach a very good The balance, that is to say, the prepared material has high volume density, small porosity, small thermal expansion coefficient, high mechanical strength, and excellent physical and chemical indicators of graphite. The bulk density of the graphene-carbon graphite composite material prepared by the present invention is more t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com