Method for synthersizing iron oxide black by taking lime as raw material

A technology of lime and iron black, which is applied in the field of synthesizing iron black with lime as raw material, can solve the problems of high price of liquid caustic soda and high production cost, and achieve stable product quality, low production cost and good market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

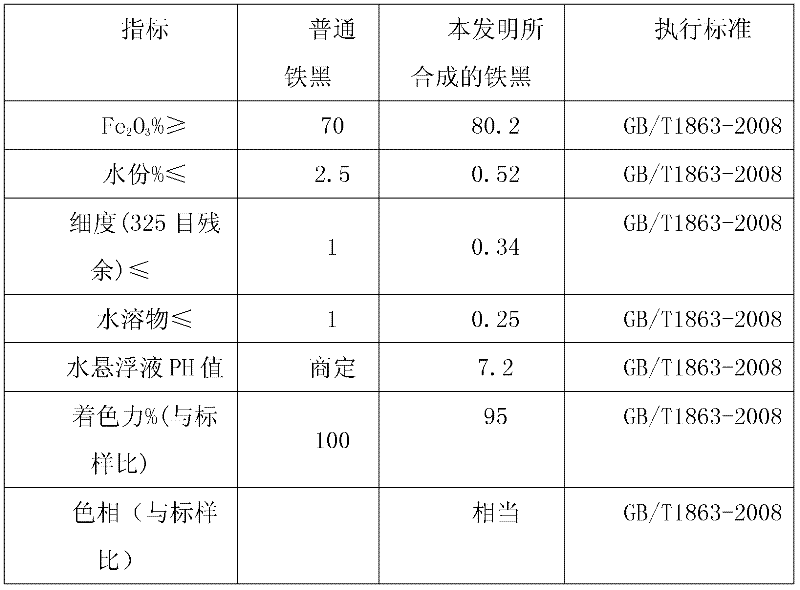

Image

Examples

Embodiment Construction

[0021] A kind of method taking lime as raw material synthetic iron black is characterized in that comprising the following steps:

[0022] (1), lime and water are digested according to the ratio of mass ratio 1: 1, after digesting, the mass ratio of lime and water is 1: 3 and then add water and stir and mix, slaking into a lime emulsion slurry with a solid content of 30%, Then sieve to remove solid impurities to obtain sieved lime milk slurry;

[0023] (2), the lime emulsion slurry and ferrous sulfate solution that step (1) gained sieves press FeSO 4 : Cao=2.7: 1 mixing, adding water to adjust the solid content is 8-10%, to obtain mixed slurry, adjust the pH value of the mixed slurry with milk of lime to be 7.5-8.5, feed steam and heat up to 95-98 ℃, and then After passing through the air for 3 hours to oxidize, compare it repeatedly with the standard sample, stop the reaction after reaching the production index of iron black, and discharge the material to obtain the reacted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com