Preparation method of enzyme biosensor for detecting formaldehyde gas

A biosensor and formaldehyde gas technology, applied in the field of sensors, can solve the problems of poor selectivity of formaldehyde gas sensors, susceptibility to interference from other gases, poor stability, etc., and achieve high gas collection efficiency, simple structure, and increased surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

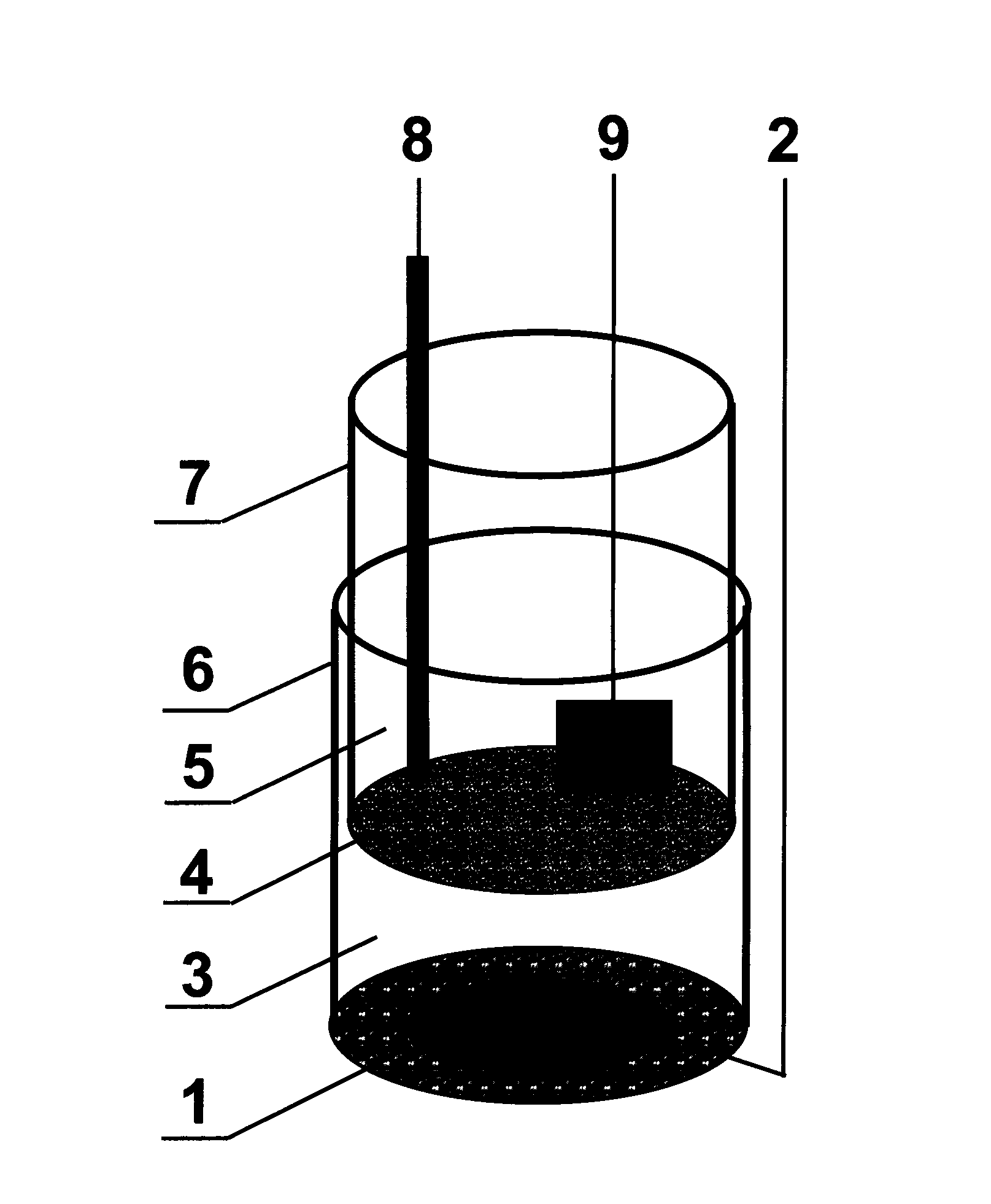

[0030] A polytetrafluoroethylene membrane (thickness 200-300 μm, porosity > 30%, pore size 1-5 μm) was attached to a carbon foam electrode (a disc with a thickness of 1-3 mm), and the edges were bound to a cylindrical plexiglass sleeve made working electrode.

[0031] The reaction chamber of the sensor is composed of two cylindrical plexiglass sleeves with different diameters. The small sleeve can be inserted into the large sleeve just right, and there is no liquid leakage between the contact surfaces of the two cylinder walls. The reaction chamber contains a three-electrode system. The polytetrafluoroethylene film in contact with the foam carbon sheet is bundled at the bottom of the large sleeve to form a working electrode, and then an enzyme-containing electrolyte solution is added into the large sleeve. Bind the dialysis membrane (MWCO 12-14kDa) on the bottom of the small sleeve, and then insert the small sleeve into the inside of the large sleeve until the dialysis membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com