Patents

Literature

59results about How to "Facilitate through" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fat emulsion injection of 'Xingnaojing' and its preparing process

InactiveCN1628779AHigh purityFully extractedMammal material medical ingredientsEmulsion deliveryHas active ingredientEmulsion

Disclosed is a fat emulsion injection of 'Xingnaojing' and its preparing process, which comprises using supercritical extraction technology and macroscopic adsorption resin technology for isolating and purifying the water soluble and fat soluble parts in the medicinal materials including musk, cape jasmine, and curcuma root, finally utilizing emulsion technology to obtain the end product.

Owner:JIANGSU QINGJIANG PHARMA

Nanometer thermal insulation material of automobile glass and manufacturing method thereof

InactiveCN102153948AStrong absorption capacityFacilitate throughRadiation-absorbing paintsReflecting/signal paintsInfraredIndium

The invention discloses a manufacturing method of a nanometer thermal insulation material of automobile glass. The nanometer material mainly comprises the following components according to content percentage: 50-70% of nanometer modified organic silica solution, 5-10% of nanometer oxidized silica solution, 5-15% of nanometer indium tin oxide size, 10-20% of organic solvent and 1-5% of film forming substances, and the total percentage of all the components is 100%. By adopting the method, the nanometer size with the function of thermal insulation forms a film on the inner surface of the automobile glass through an organic silicon carrier, so that the glass has the function of thermal insulation, as well as very high visible light transmission, an excellent infrared rejection rate, an excellent ultraviolet absorption rate, prominent adhesion and ultrahigh film hardness.

Owner:李海洋

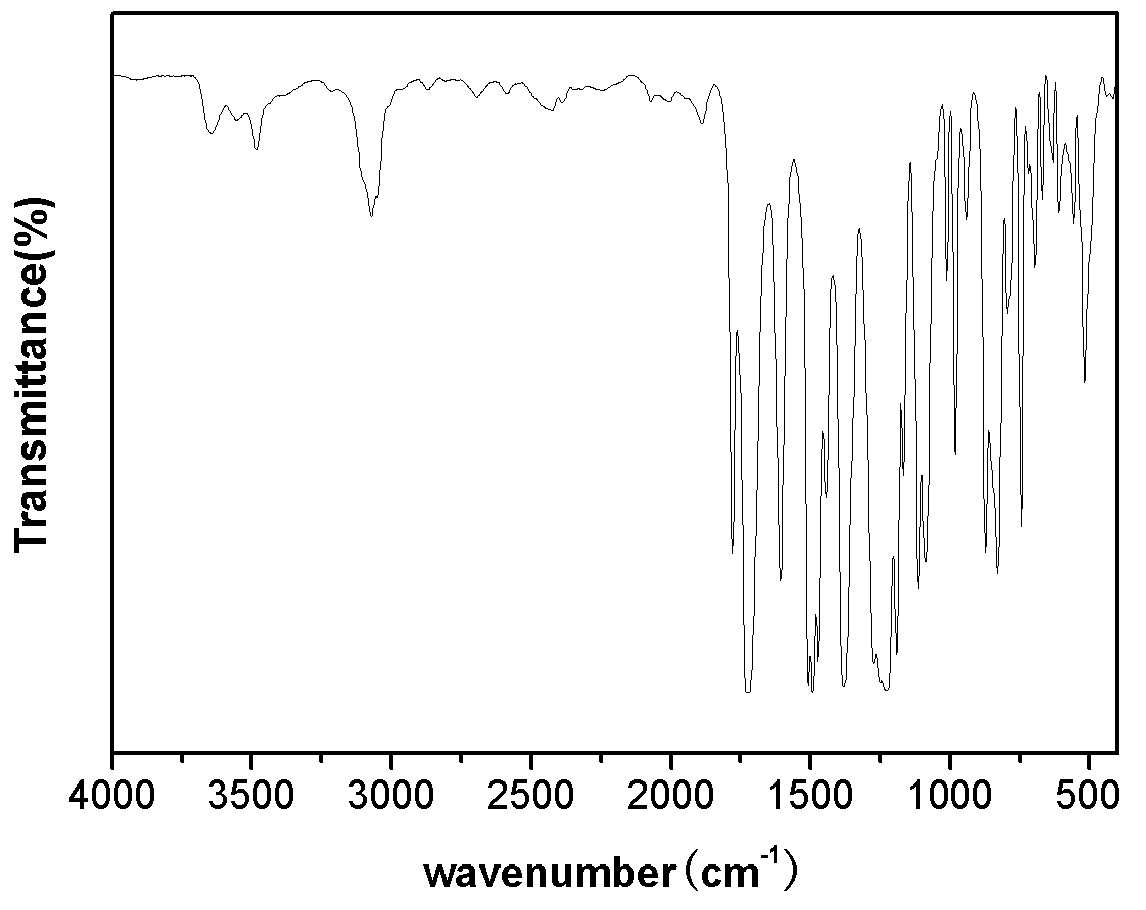

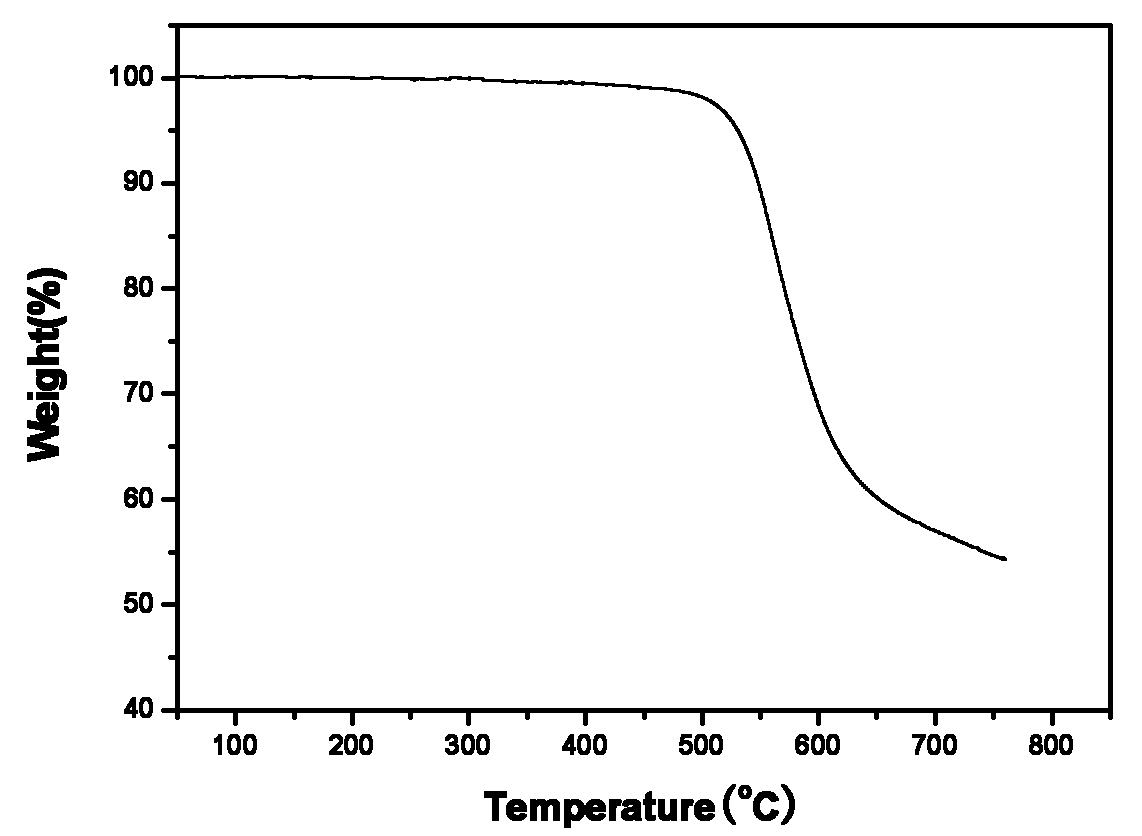

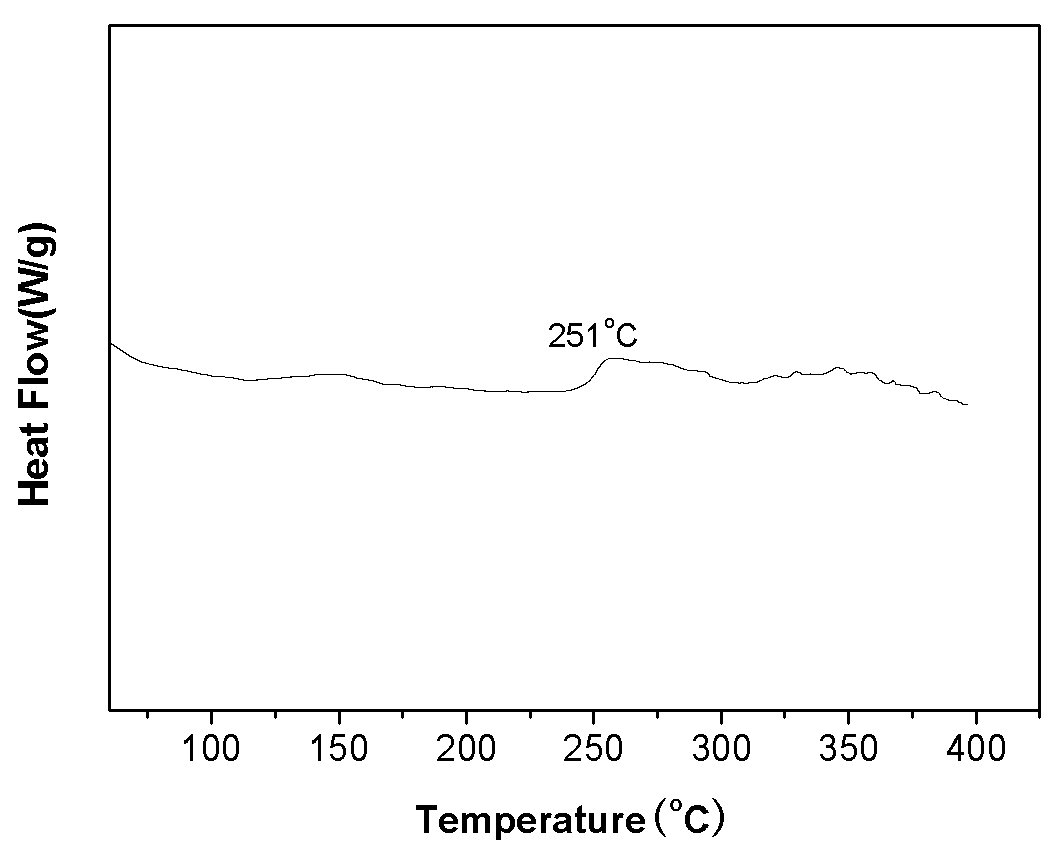

Polyimide film and preparation method and applications thereof

ActiveCN102167824AHigh transparencyReduced solar absorption and emission ratioDiphenyl etherOptical transparency

The invention discloses a polyimide film and a preparation method and applications thereof. The compound forming the polyimide film is the compound of which structural general formula is shown in the formula I. The preparation method of polyimide is as follows: aromatic dianhydride 2,3,3',4'-diphenyl ether tetracarboxylic acid dianhydride (aODPA) and a series of aromatic diamine monomers are used as raw materials to prepare polyimide resin through chemical imidization. The polyimide film prepared by the technology has good optical transparency, low solar absorptivity-emissivity ratio and good thermal stability, and can be used to prepare the thermal protection device of the spacecraft, the solar cell array substrate and the antenna reflector / collector or solar sail and have important application value.

Owner:INST OF CHEM CHINESE ACAD OF SCI

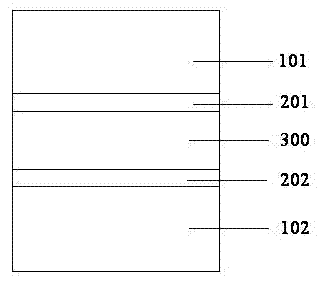

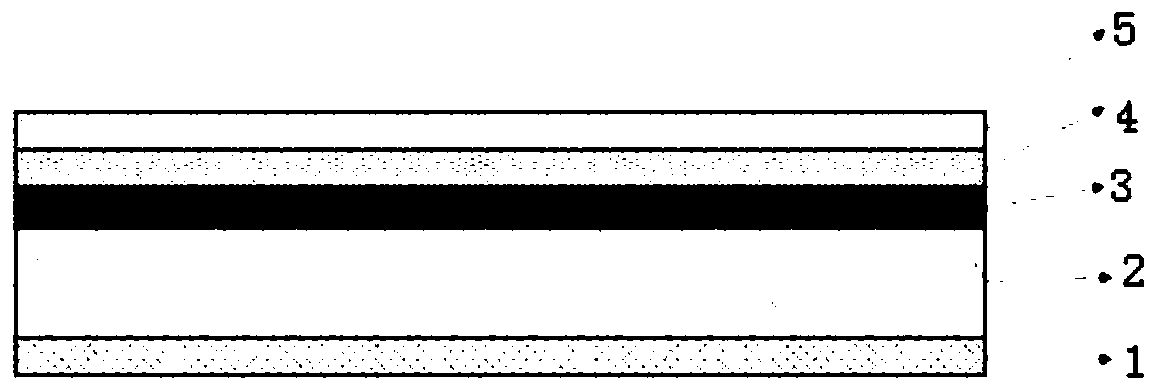

Flexible thin film solar cell and packaging method thereof

InactiveCN102254975AImprove photoelectric conversion efficiencyHigh light transmittanceFinal product manufactureSynthetic resin layered productsEngineeringEthylene-vinyl acetate

The invention discloses a flexible thin film solar cell, which comprises a solar cell layer and a packaging layer, wherein the packaging layer comprises a first packaging layer and a second packaging layer; the solar cell layer is packaged between the first packaging layer and the second packaging layer; and the packaging layer consists of a first ethylene vinyl acetate (EVA) crosslinking layer, a second EVA crosslinking layer, a first Teflon layer and a second Teflon layer. The invention also provides a packaging method, which comprises the following steps of: 1, arranging the first Teflon layer, the first EVA crosslinking layer, the solar cell layer, the second EVA crosslinking layer and the second Teflon layer in turn to form a five-layer structure; and 2, laminating and packaging the five-layer structure in the step 1. In the flexible thin film solar cell manufactured by the packaging method, Teflon plastic layers are introduced to serve as packaging materials, so that the photoelectric conversion efficiency of the solar cell is obviously improved, and the cost of packaging the solar cell is reduced.

Owner:上海联孚新能源科技集团有限公司

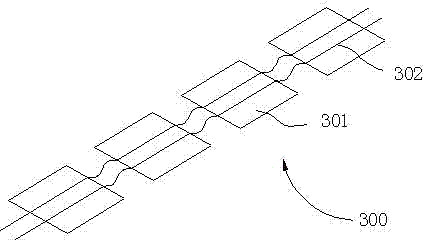

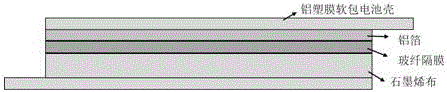

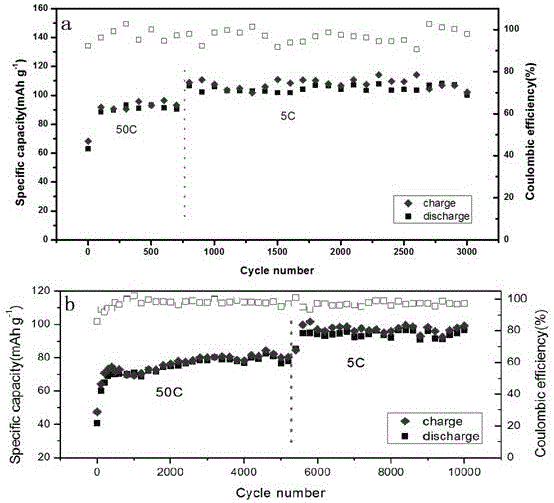

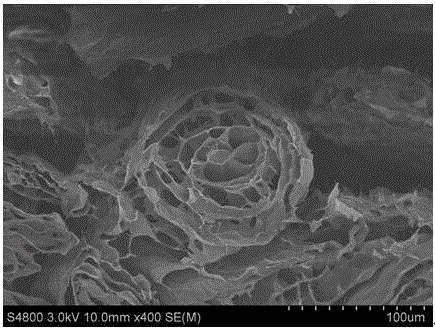

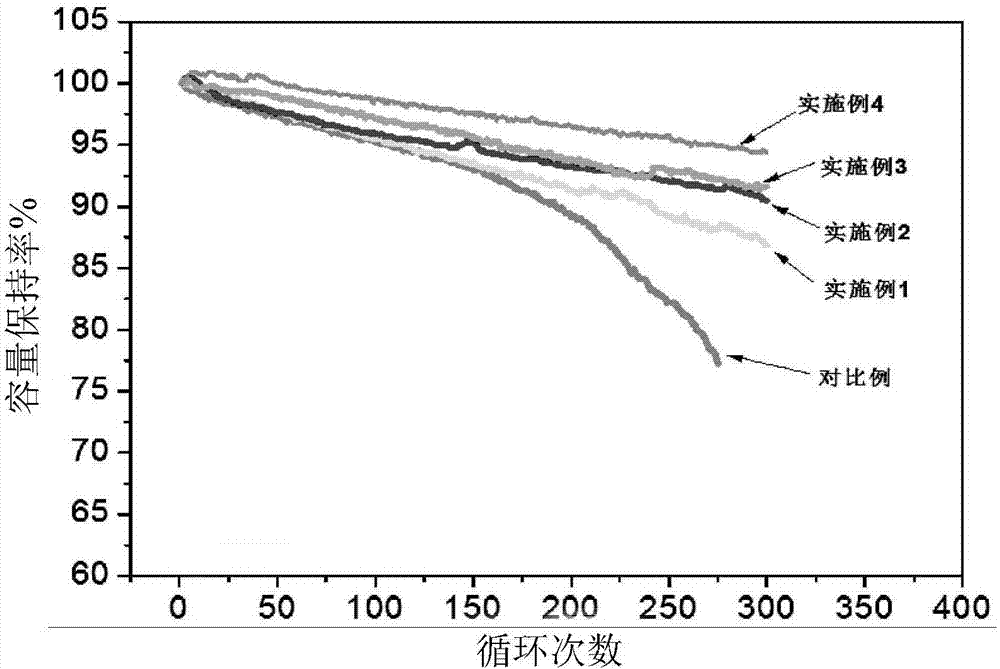

Preparation method for flexible and bendable aluminum ion battery

The invention discloses a preparation method for a flexible and bendable aluminum ion battery. The preparation method comprises the steps of extruding graphene oxide or a graphene oxide inorganic salt mixed solution to rotary inorganic salt solution coagulating bath in spinning equipment with certain diameter; then filtering and collecting short fibers from the coagulating bath by a filtering net, and lapping joint the short fibers into graphene oxide cloth; reducing the obtained graphene oxide cloth in a reduction temperature to obtain graphene cloth; and then assembling the obtained graphene cloth positive electrode material, a diaphragm, a negative electrode, an electrolyte and a battery shell to obtain the aluminum ion battery taking the graphene cloth as the positive electrode material. The flexible and bendable aluminum ion battery is green, environment-friendly and low in cost, and suitable for continuous and controllable large-scale industrial production; under the premise of ensuring relatively high energy density, power density and cycle life of the aluminum ion battery, the flexibility and bendable property of the battery are realized; and the flexible and bendable aluminum ion battery is applicable to the field of high-safety wearable energy storage devices.

Owner:杭州德烯科技集团有限公司

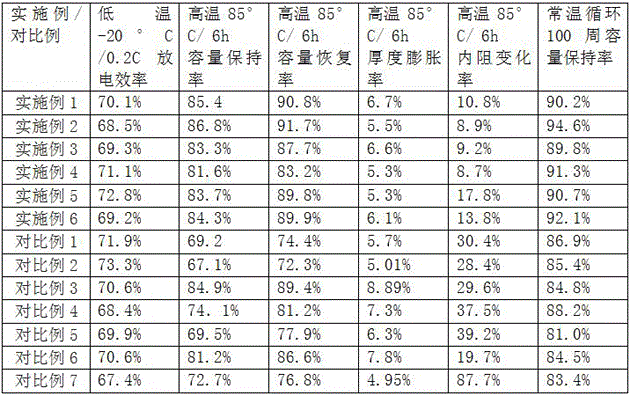

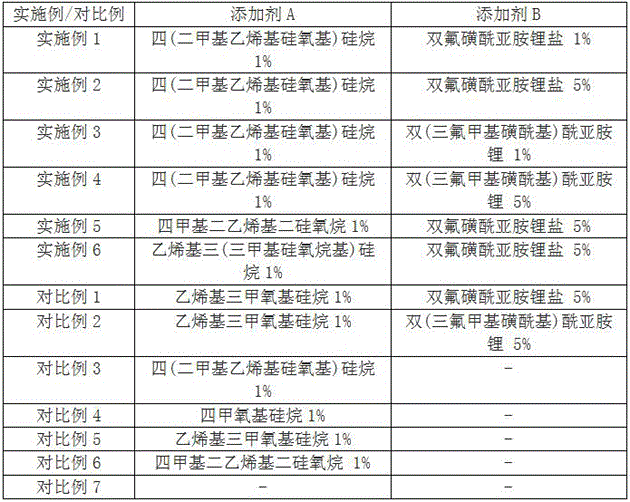

Non-aqueous electrolyte of silicon-based anode lithium ion battery

InactiveCN106129473AIncrease elasticityReduce consumptionSecondary cellsOrganic electrolytesSolventLithium electrode

The invention aims to provide a non-aqueous electrolyte of a silicon-based anode lithium ion battery with excellent charging and discharging cycle and high-temperature storage performance. The non-aqueous electrolyte consists of a solvent, a lithium salt, an unsaturated siloxanes additive A and a fluoro-sulfimide additive B, wherein the proportion, relative to the total weight of the non-aqueous electrolyte, of the additive A is 0.1% to 3%; the proportion, relative to the total weight of the non-aqueous electrolyte, of the additive B is 0.1% to 10%; the solvent comprises cyclic carbonate and / or chain carbonate; and the molar concentration of the lithium salt in the solvent is 0.8 to 1.5 mol / L. According to the non-aqueous electrolyte provided by the invention, the high and low temperature performance and the cycle performance of the silicon-based anode lithium ion battery can be comprehensively promoted. The non-aqueous electrolyte can be applied to the field of lithium ion batteries.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

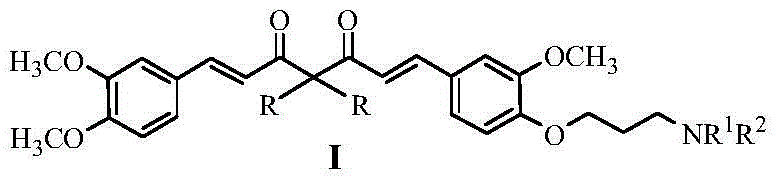

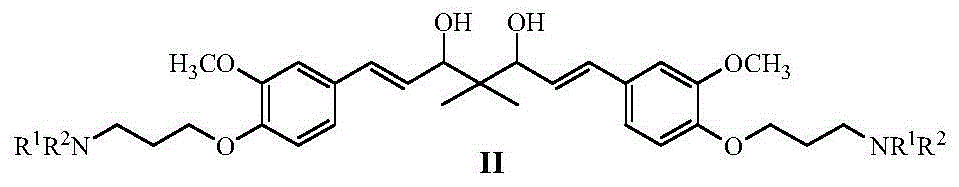

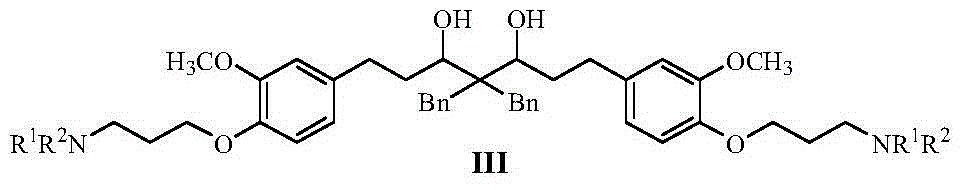

Curcumin analogues and preparation and application thereof

ActiveCN105348219AGood water solubilityHigh activityOrganic compound preparationAntineoplastic agentsActive componentStereochemistry

The invention belongs to the field of medical technology and relates to preparation and application of a series of curcumin analogues. The curcumin analogues have structures as shown in the formula I, formula II and formula III, wherein R, R1 and R2 are as mentioned in the specification. Pharmaceutically acceptable salt and solvate of the curcumin analogues and a medicine containing the curcumin analogues or the pharmaceutically acceptable salt used as active components can be used in treatment of cancer. The curcumin analogues and the pharmaceutically acceptable salt have a good anticancer activity. A preparation method of the curcumin analogues is simple and feasible and is easy to operate.

Owner:SHENYANG PHARMA UNIVERSITY

Method for synthesizing monoclinic phase mesoporous bismuth vanadate through template method

InactiveCN102992402AImprove photocatalytic activitySimple processVanadium compoundsMetal/metal-oxides/metal-hydroxide catalystsTube furnaceSolid product

The invention relates to a method for synthesizing monoclinic phase mesoporous bismuth vanadate through a template method. The method comprises the following steps of: mixing nitric acid, ethanol and bismuth nitrate which are weighed in a mass ratio of 1:(2.8-28):(0.2-1) by ultrasonic wave, so as to obtain a bismuth nitrate solution; mixing nitric acid, ethanol and ammonium meta-vanadate which are weighed in a mass ratio of 1:(2.8-28):(0.05-0.25) by ultrasonic wave, so as to obtain an ammonium meta-vanadate solution; dropping the ammonium meta-vanadate solution slowly into the bismuth nitrate solution, so as to obtain a mixed solution; adding silicon dioxide aerogel microspheres to be used as a template, evacuating in order to fully inject the mixed solution in the template, reacting for 6 hours to 24hours at the temperature of 60 DEG C to 110 DEG C, so as to obtain solid products; and finally, heating the solid products to 160 DEG C to 400 DEG C in a tube furnace at the heating rate of 0.5 DEG C per minute to 10 DEG C per minute, roasting for 2 hours to 24 hours, naturally cooling to room temperature, and then removing the template by using a sodium hydroxide solution to obtain the monoclinic phase mesoporous bismuth vanadate with average aperture distribution (1nm to 20nm). The method provided by the invention is simple and easy to control in process and is environment-friendly; and the monoclinic phase mesoporous bismuth vanadate obtained by the method has excellent photo-catalytic performance within the range of visible light.

Owner:TONGJI UNIV

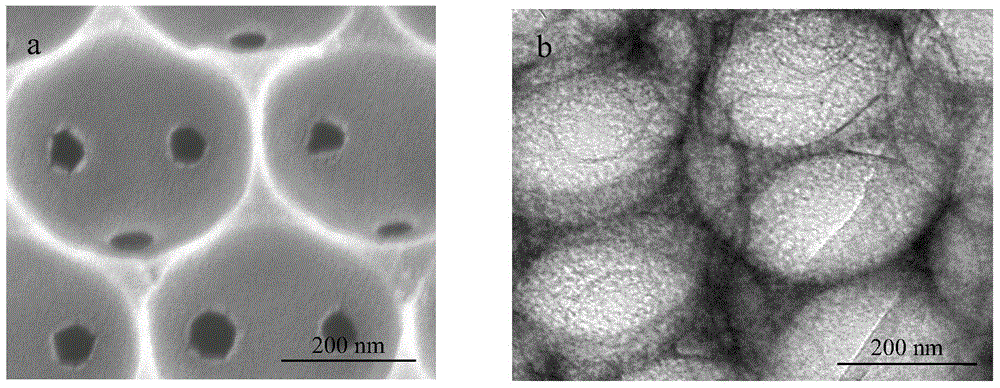

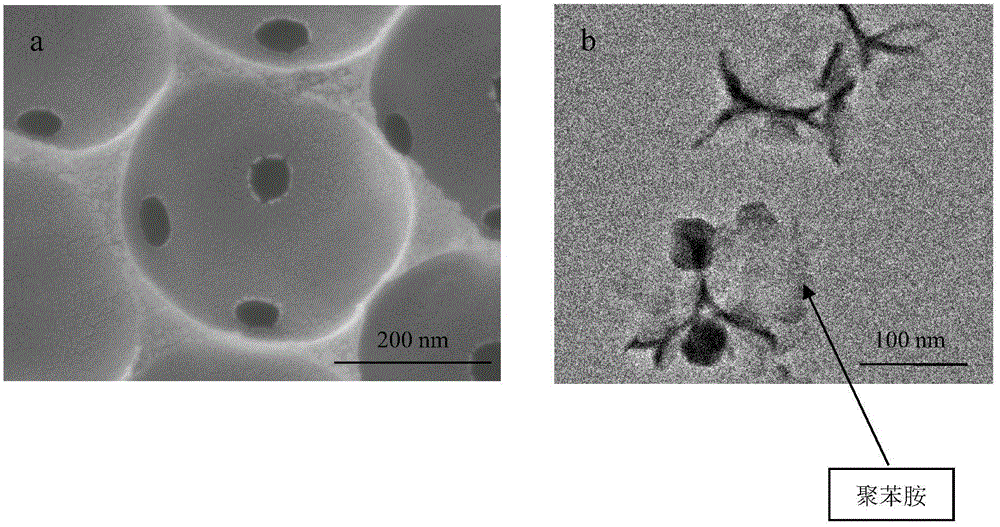

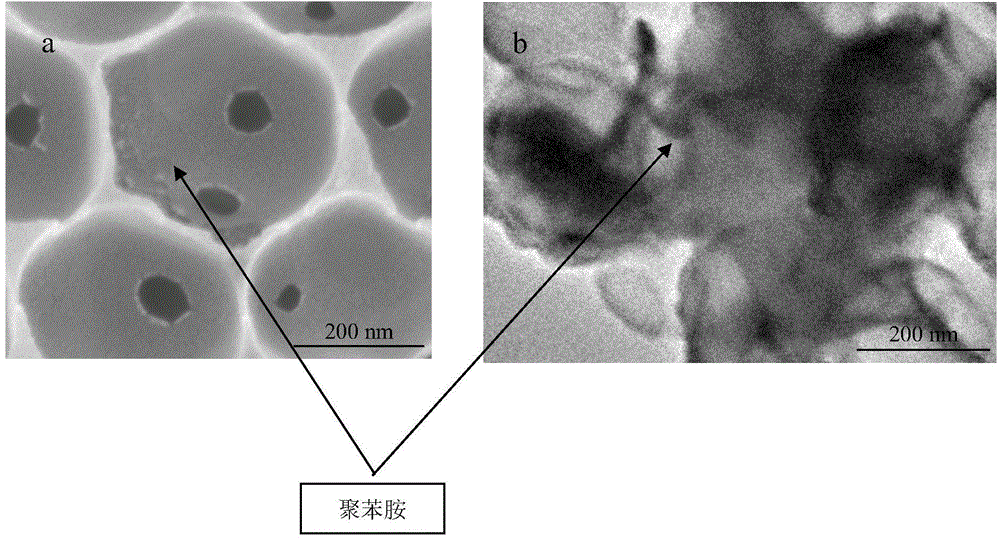

Preparation method of 3D ordered macroporous polyaniline (OM PANI)/TiO2 composite photocatalytic material and application thereof

InactiveCN104383966AAvoid disadvantages that affect catalytic efficiencyEasy to makeWater/sewage treatment by irradiationOrganic-compounds/hydrides/coordination-complexes catalystsAnilineDiethyl ether

The invention belongs to a preparation method of a 3D ordered macroporous polyaniline (OM PANI) / TiO2 composite photocatalytic material and application thereof. The preparation method comprises the following steps: A, dipping 3-10g of prepared 3D OM PANI / TiO2 material in 50ml of a hydrochloric acid containing 0.05-0.5ml of an aniline monomer, and carrying out ultrasonic oscillation for 5-20 minutes; B, putting a reaction system in the step A into ice bath, dropwise adding a monomer initiator with the concentration of 0.25-1%, and reacting for 2-5 hours; C, washing a sample by adopting ethyl alcohol and / or diethyl ether, and washing the sample with distilled water; D, drying at the low temperature of 60-80 DEG C so as to obtain the sample. The 3D OM PANI / TiO2 composite material is used for combining the favorable conducting performance of PANI as well as characteristics of the relatively low energy gap with the TiO2 catalytic performance, meanwhile improves the defects that the photoproduction electron-hole recombination rate of a single TiO2 material is high and the visible light response is poor, and achieves the effects of improving the TiO2 photocatalytic quantum efficiency and reinforcing the visible light absorption; meanwhile, the material is at hundreds of nanoscales, is difficult to reunite, is easy to settle, and is good in regeneration performance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

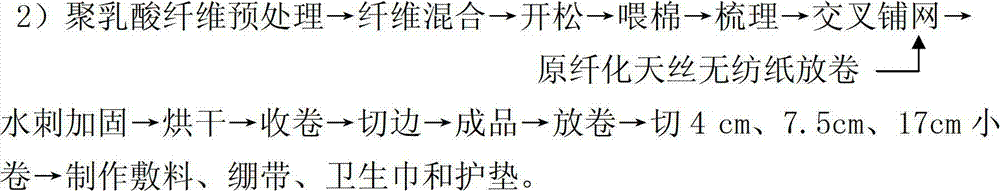

Non-allergenic fully-degradable medical and hygienic non-woven material capable of adjusting moisture

ActiveCN102733096AStrong and goodGood skin affinityPulp beating methodsNon-woven fabricsPolymer chemistryPolylactic acid

The invention discloses a non-allergenic fully-degradable medical and hygienic non-woven material capable of adjusting moisture, and aims to solve the problem that the conventional degradable medical and hygienic materials are mainly made by a spunbonding method, and certain production processes are complex. The non-allergenic fully-degradable medical and hygienic non-woven material consists of the following raw materials of 60 to 80 mass percent of polylactic acid fibers and 20 to 40 mass percent of Tencel fibers and is prepared by the following steps of: preparing Tencel fiber non-woven paper by a wet laying method, wherein part of the Tencel fiber non-woven paper is fibrillated; pre-treating the polylactic acid fibers and preparing a polylactic acid fiber web; unreeling the non-woven paper on the polylactic acid fiber web once again, interweaving the fibrillated Tencel fibers with the polylactic acid fiber web by a high-pressure spraying method, and fibrillating the Tencel fibers further; and drying at proper temperature to bind the fibrillated Tencel fibers to the periphery of the polylactic acid fibers firmly. The non-allergenic fully-degradable medical and hygienic non-woven material has the characteristics of non-allergenic property and capacity of adjusting the moisture, and can be degraded fully after being discarded.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

Silicon-based anode lithium-ion battery electrolyte

InactiveCN106910934AFacilitate throughImprove solubilitySecondary cellsOrganic solventPhysical chemistry

The invention provides silicon-based anode lithium-ion battery electrolyte which comprises an organic solvent, lithium salt, a film formation additive and a function additive, wherein the film formation additive comprises fluoro carbonic ester and tri-(pentafluorophenyl)borane, and the additive amounts of fluoro carbonic ester and tri-(pentafluorophenyl)borane respectively take 1%-15% and 0.1%-5% of the total mass of the electrolyte. According to the electrolyte, a stable, uniform and flexible SEI (solid electrolyte interface) film is formed on the surface of a silicon-based anode and can endure volume expansion of the silicon-based anode in repeated charging and discharging processes, so that the cycle performance of a battery is enhanced.

Owner:OPTIMUM BATTERY CO LTD

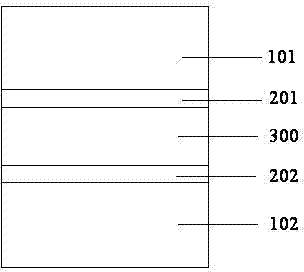

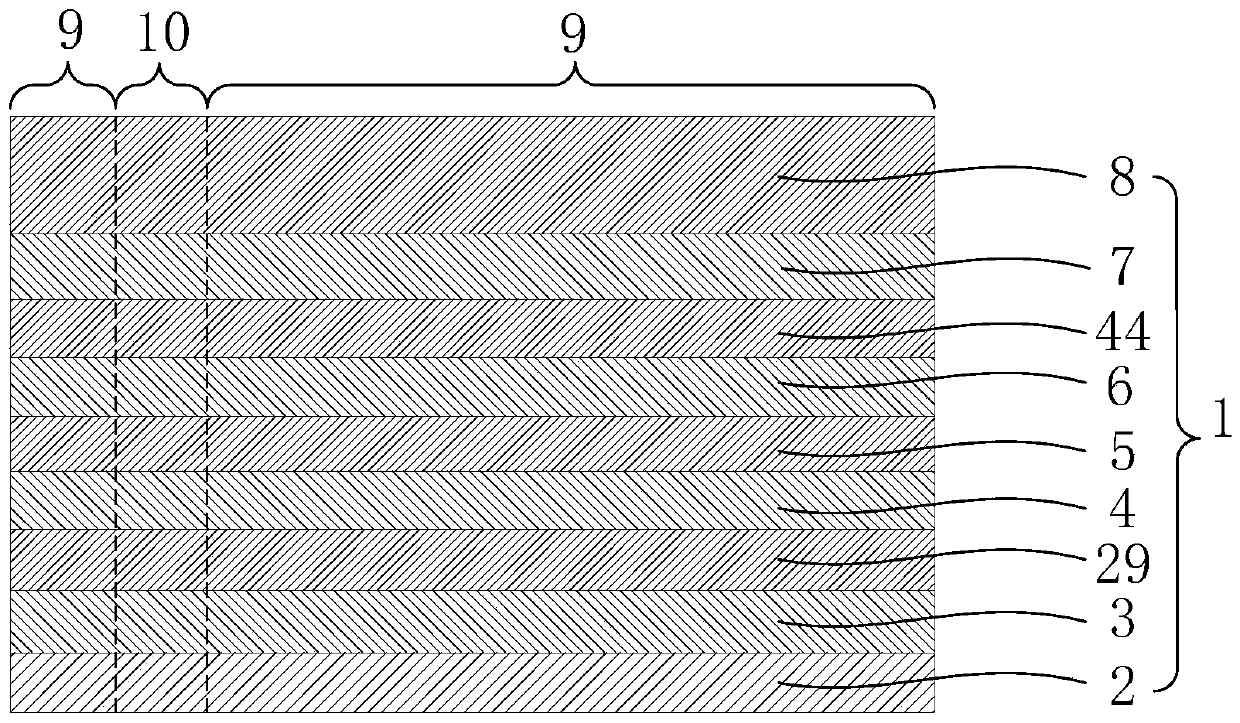

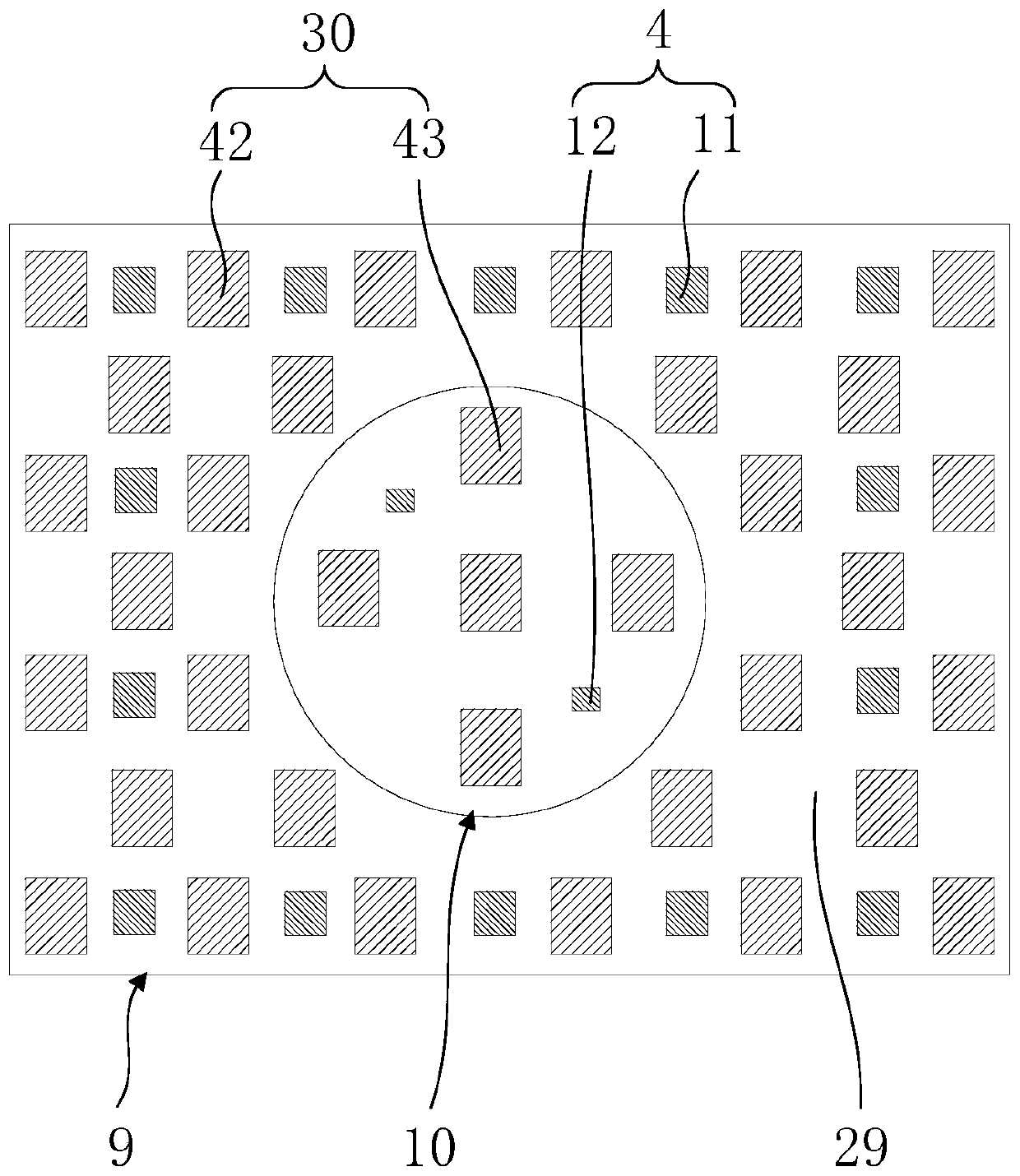

Display panel and display device

ActiveCN111583818AFacilitate throughRealize full screen displayTelevision system detailsSolid-state devicesDisplay deviceMaterials science

The invention discloses a display panel and a display device. The display panel comprises an array substrate, a supporting layer and a light-emitting function layer, wherein the supporting layer and the light-emitting function layer are sequentially arranged on the array substrate. The display panel is provided with a display area and a sensor lighting area arranged in the display area, and the light-emitting function layer is located in the display area and the sensor lighting area. The supporting layer comprises a plurality of first supporting columns which are located in the display area and arranged at intervals, and a plurality of second supporting columns which are located in the sensor lighting area and arranged at intervals. The distribution density of the second supporting columnsis smaller than that of the first supporting columns. Full-screen display can be achieved, and the light transmittance of the sensor lighting area can also be improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

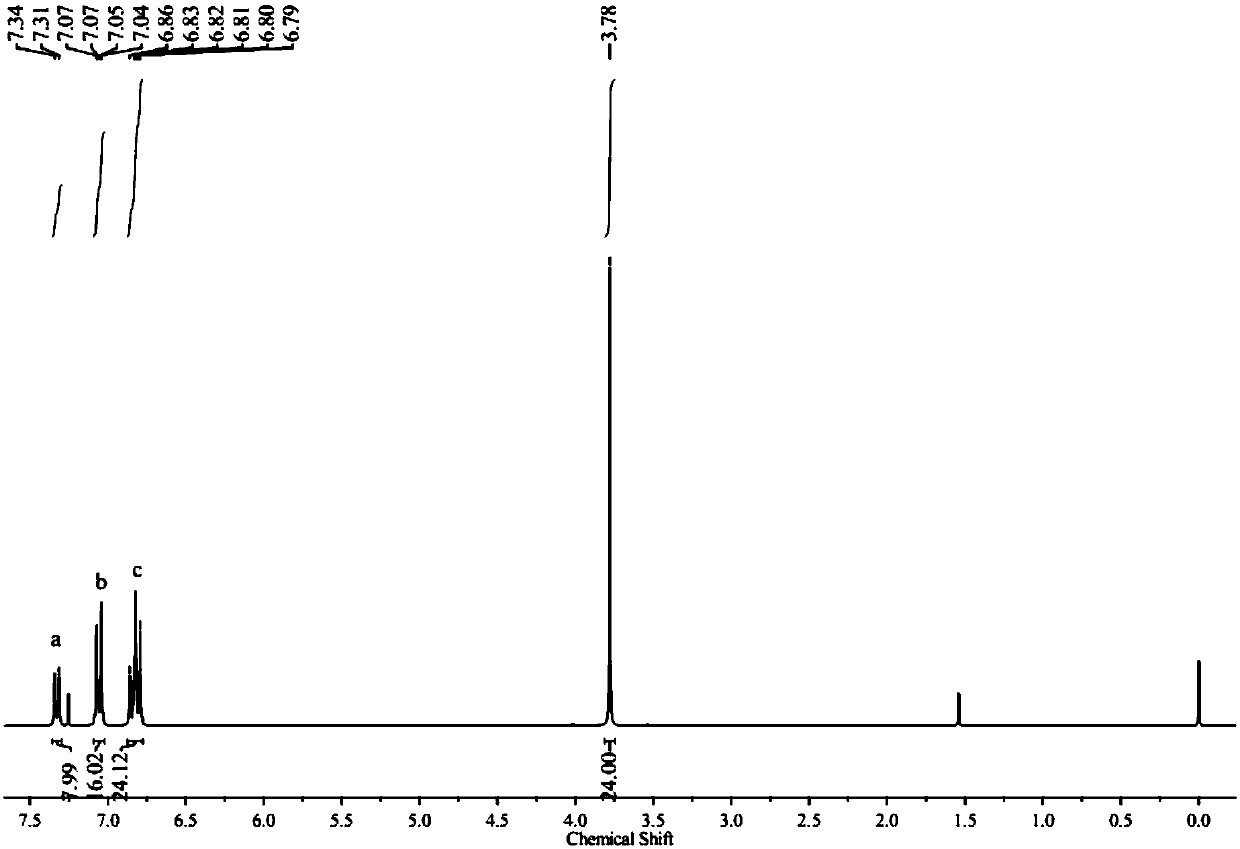

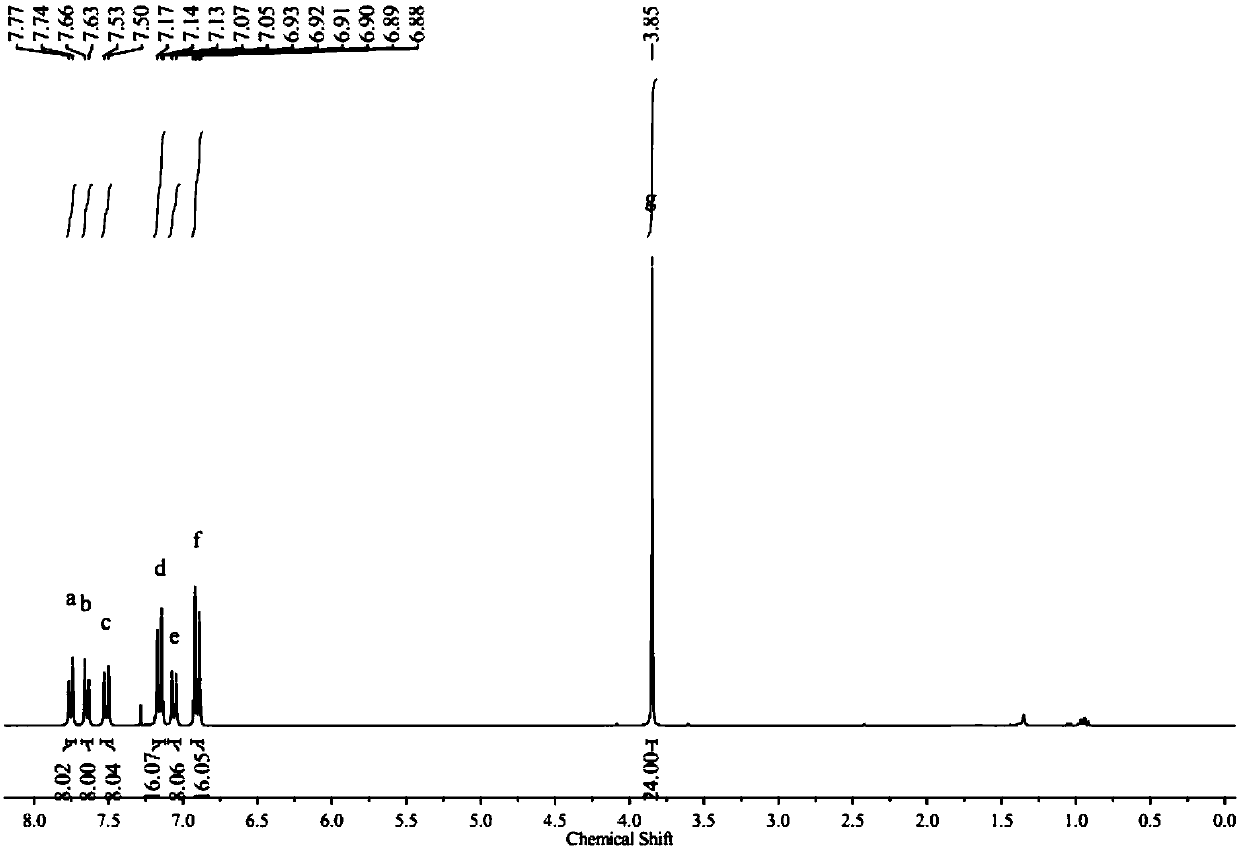

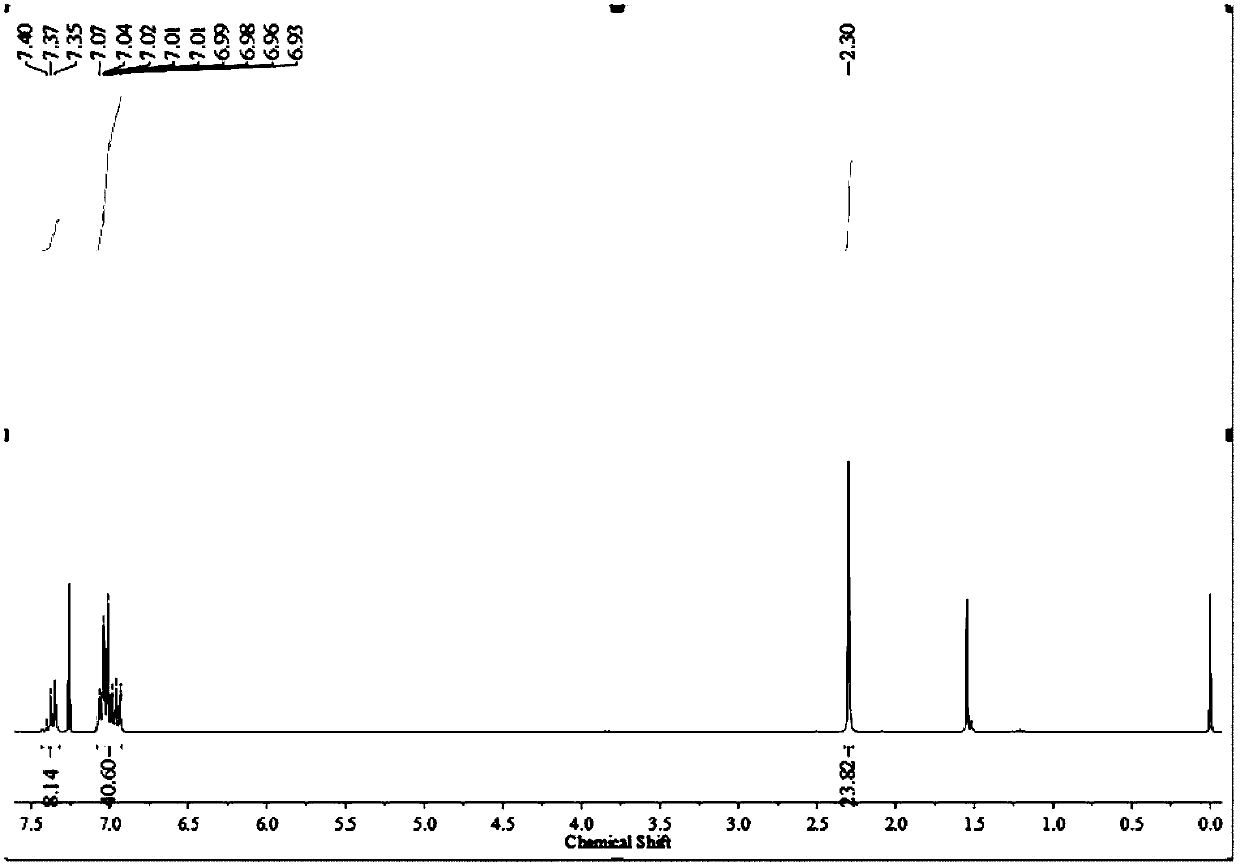

Silicon-based triphenylamine derivative, preparation method thereof and application thereof in perovskite solar cell

ActiveCN108117568AImprove performanceImprove transmittanceGroup 4/14 element organic compoundsFinal product manufactureStructural formulaCrystallinity

The invention discloses a silicon-based triphenylamine derivative, a preparation method thereof and application thereof in a perovskite solar cell. In a chemical structural formula of the silicon-based triphenylamine, substituent groups are hydrogen, methyl, methoxyl, a methylthio group and a methylseleno group, and the substituent groups can be at any substitution site of a benzene ring. The silicon-based triphenylamine derivative material is not only simple in synthesis steps and has relatively high synthetic yield, and raw material cost is extremely low, a device preparation technology is simplified after the silicon-based triphenylamine derivative material is applied to a hole transport layer of a p-i-n type planar perovskite solar cell, and conversion efficiency of the solar cell alsocan be obviously improved, so that a good application prospect is shown; besides, it is worth mentioning that the silicon-based triphenylamine derivative disclosed by the invention has good crystallinity when m is equal to 0 and is not in an amorphous form, which is infrequent in other hole transport materials, and good crystallinity after annealing is beneficial to further improvement of hole transmission rate of the silicon-based triphenylamine derivative and increase of current of the solar cell and a fill factor.

Owner:SUZHOU UNIV +1

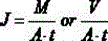

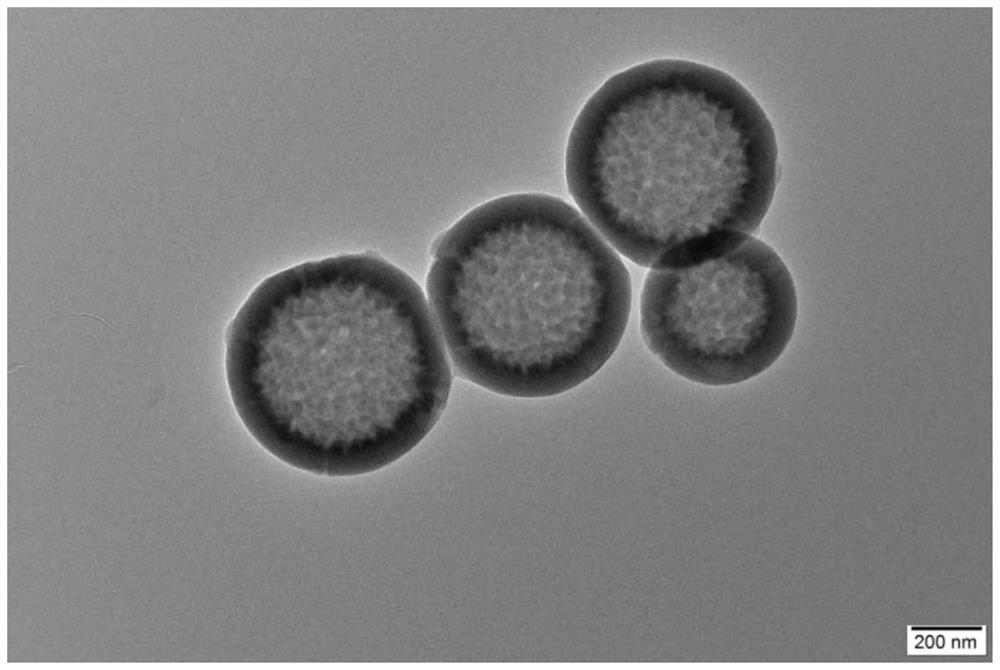

Preparation method of novel polyphenylene sulfone solvent-resistant nanofiltration membrane containing modified micropore spheres

The invention discloses preparation of modified micropore spheres on the basis of a ZIF-8 type metal-organic framework material and a preparation method for preparing a novel polyphenylene sulfone solvent-resistant nanofiltration membrane by applying the modified micropore spheres. The method comprises the steps that ZIF-8 nanoparticles grow inside macropore spheres and on the surfaces of the macropore spheres, and the modified micropore spheres are obtained; the modified novel micropore spheres are added to a polyphenylene sulfone membrane casting solution, and the novel polyphenylene sulfone solvent-resistant nanofiltration membrane containing the modified micropore spheres is prepared through an immersion-phase conversion method. The reparation method of the novel polyphenylene sulfone solvent-resistant nanofiltration membrane containing the modified micropore spheres has the advantages that nano-scaled porous structures of the modified micropore spheres are utilized for improving the pore structure of the polyphenylene sulfone membrane, large-size solute molecules in the organic solution are effectively intercepted, and fluid channels, facilitating solvent permeation, in the membrane are increased; when the addition ratio of the modified micropore spheres is 1.0 wt%, the membrane property is the best, and the permeation flux and interception rate can be increased simultaneously.

Owner:BEIJING FORESTRY UNIVERSITY

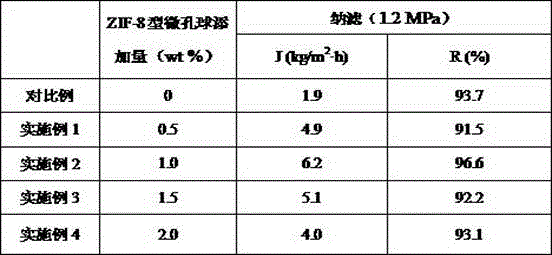

Brinzolamide nanosuspension used for eyes and preparation method thereof

InactiveCN104721136AMedication convenienceImprove bioavailabilityPowder deliveryOrganic active ingredientsDiseaseSide effect

The invention relates to the field of medicines and in particular relates to a brinzolamide nanosuspension preparation used for eyes as well as a preparation method and application thereof, aiming to lengthen the residence time of the preparation on the eyes or improve the bioavailability of the preparation. The preparation can be used for treating the diseases, such as intraocular hypertension and glaucoma. Gels can conduce to lengthening the retention time of the medicine on the eyes and reducing the number of times of administration and the dosage of administration, so that not only is the patient compliance improved but also the side effects of the medicine can be reduced. Meanwhile, no preservative is added and single-dosage package is adopted, thus reducing the irritation of eye drops used for a long term to the eyes and greatly improving the medication safety.

Owner:SICHUAN UNIV

Phosphorus-based organic matter intercalation structure selective infrared absorption material, preparation method and application thereof

The invention provides a phosphorus-based organic matter intercalation structure selective infrared absorption material, a preparation method and the application thereof. The infrared absorption material can be simplified into POH-LDHs, and has the molecular formula of (M2+) 1-x (Al3+) x(OH) 2(An-) a(NO3-) b. mH2O. The preparation method of the material comprises the steps of: taking hydrotalcite as precursor; adopting an ion exchange method to insert phosphorus-based organic matter negative ion into the hydrotalcite layer; and assembling, and obtaining the phosphorus-based organic matter intercalation structure selective infrared absorption material with good crystalline phase structure. The infrared absorption material has excellent infrared absorption capability, and is better in the infrared absorption effect than MgAl-CO3-LDHs, thus being a good infrared absorption material. The material is suitable for being applied to a thin polymer film of polyethylene or ethylene-vinlacetate copolymer, etc.

Owner:BEIJING UNIV OF CHEM TECH

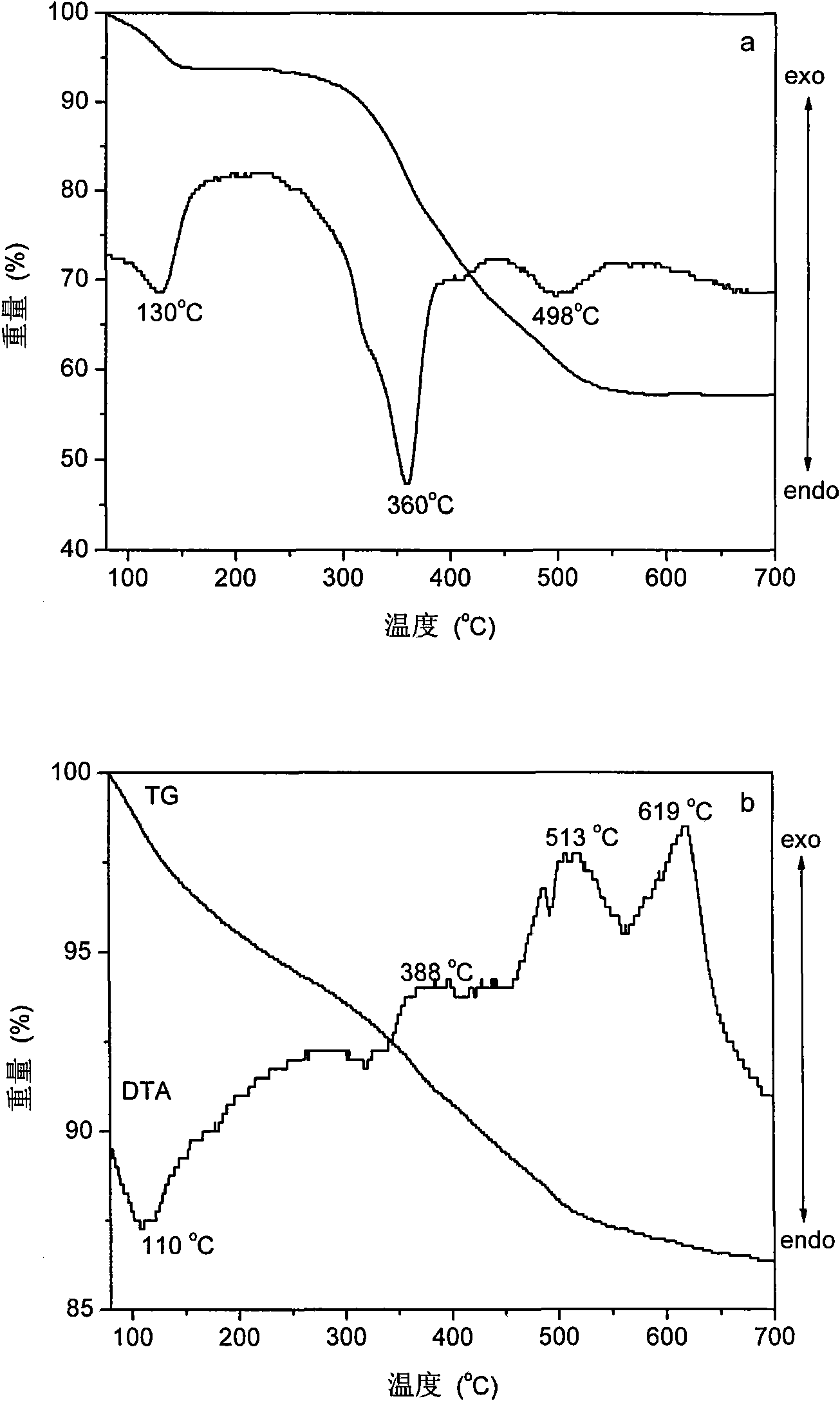

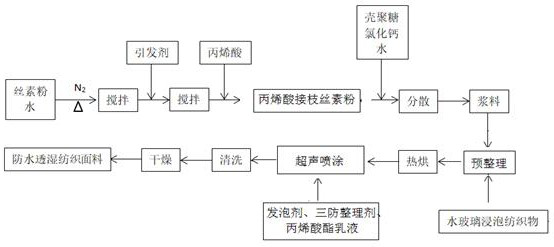

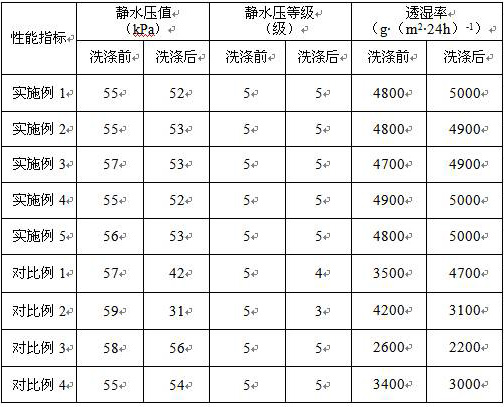

Finishing method of waterproof and moisture-permeable clothing fabric

InactiveCN111851084AGood effectFacilitate throughTextile treatment by spraying/projectingVegetal fibresFiberPolymer science

The invention provides a finishing method of a waterproof and moisture-permeable clothing fabric. The finishing method includes the steps that silk fibroin powder, an initiator and acrylic acid are added into water in sequence to react to obtain a grafted modified silk fibroin dispersion solution, then chitosan, calcium chloride and deionized water are added and made into a thick solution, then atextile is pretreated with water glass liquid and then subjected to pad steam for two times accordingly through the thick solution to obtain a pre-finished fabric, then a foaming agent, a three-proofing finishing agent and acrylic ester emulsion are made into a finishing solution, the finishing solution is sprayed on the surface of the pre-dried fabric by ultrasonic atomization to form a coating,and thus the waterproof and moisture-permeable clothing textile fabric is obtained. According to the method, the acrylic grafted silk fibroin powder with excellent water absorption performance is fixed on fabric fibers, the requirements of moisture permeability and comfort for clothing fabrics are met, the finishing solution is sprayed on the fabric surface to form the firm coating with good micropores, moisture permeability is facilitated, and the waterproofness is good.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

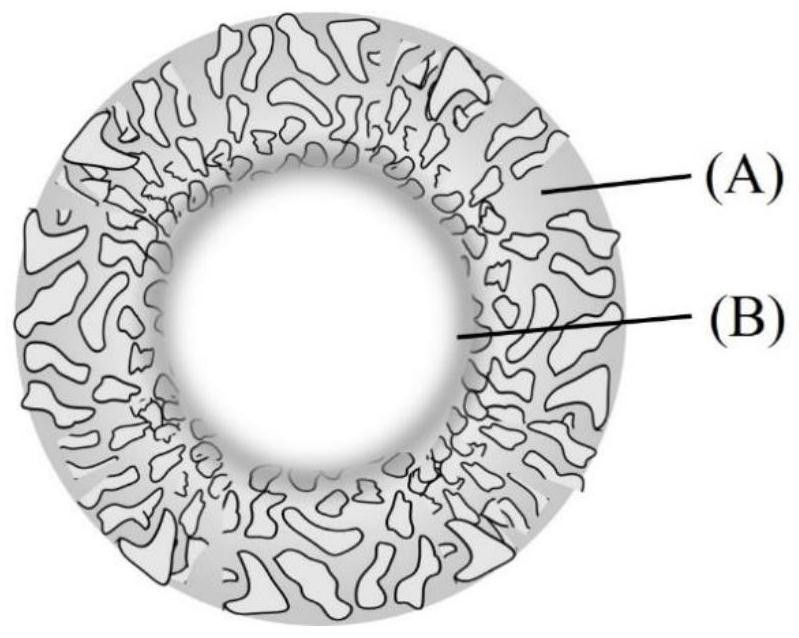

Leakproof humidifying composite hollow fiber membrane as well as preparation method and application thereof

PendingCN113926316AEasy to captureImprove permeabilitySemi-permeable membranesMembranesPolymer scienceFuel cells

The invention provides a leakproof humidifying composite hollow fiber membrane as well as a preparation method and application thereof. The leakproof humidifying composite hollow fiber membrane comprises an outer hydrophilic layer and an inner hydrophobic layer attached to the inner surface of the outer hydrophilic layer, the outer hydrophilic layer is of a spongy pore structure, the pore diameter of the outer hydrophilic layer becomes smaller from the outer surface to the inner surface, and the thickness of the inner hydrophobic layer of the leakproof humidifying composite hollow fiber membrane is smaller than that of the outer hydrophilic layer. According to the prepared leakproof humidifying composite hollow fiber membrane with the asymmetric structure of the inner hydrophobic layer and the outer hydrophilic layer, the thickness of the inner hydrophobic layer of the membrane is smaller than that of the outer hydrophilic layer, due to the fact that one side of the membrane is hydrophilic and the other side of the membrane is hydrophobic, the membrane shows asymmetric hydrophilic / hydrophobic dual performance, and the membrane is a novel membrane for humidifying treatment of a fuel cell; water molecule capture and permeation are facilitated, and meanwhile water vapor escape is facilitated.

Owner:江苏巨澜纳米科技有限公司

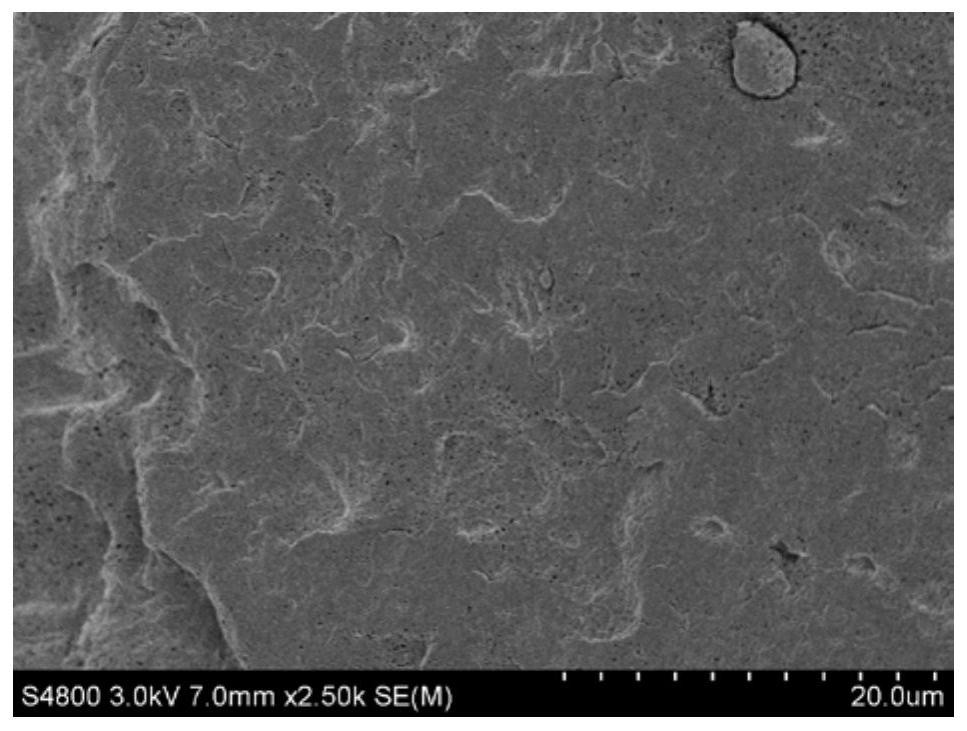

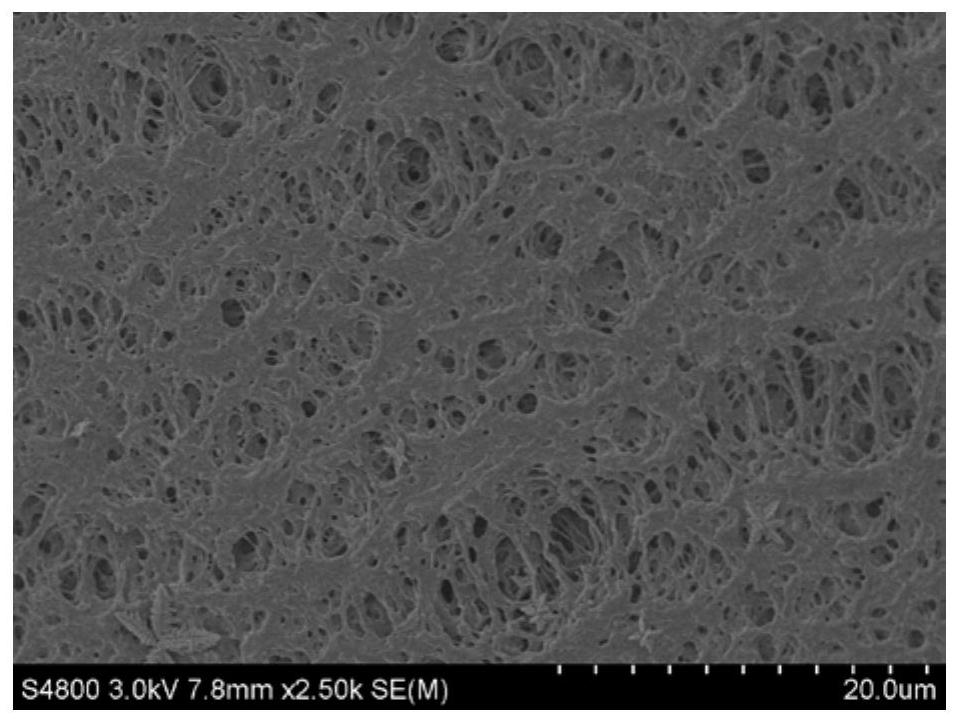

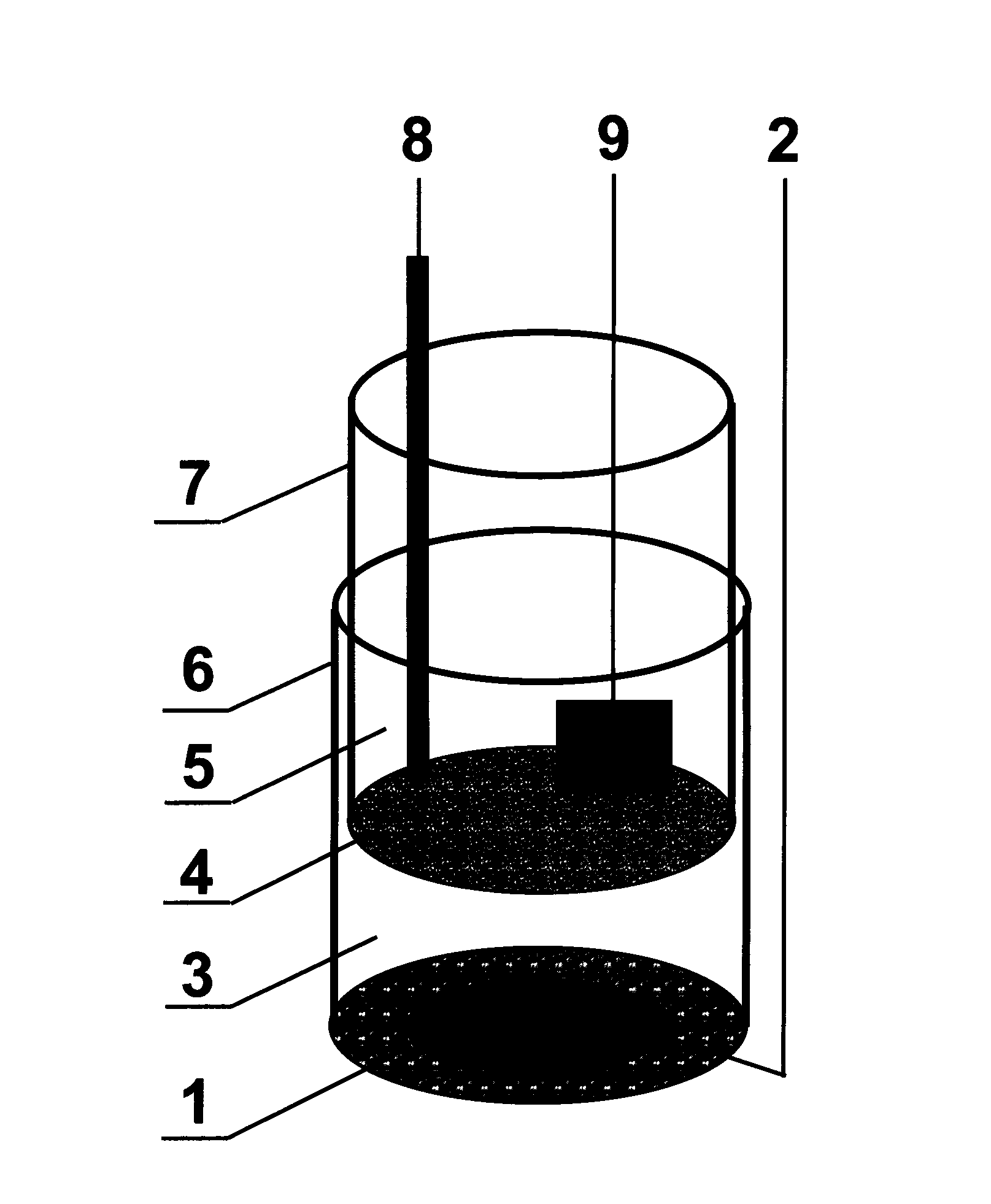

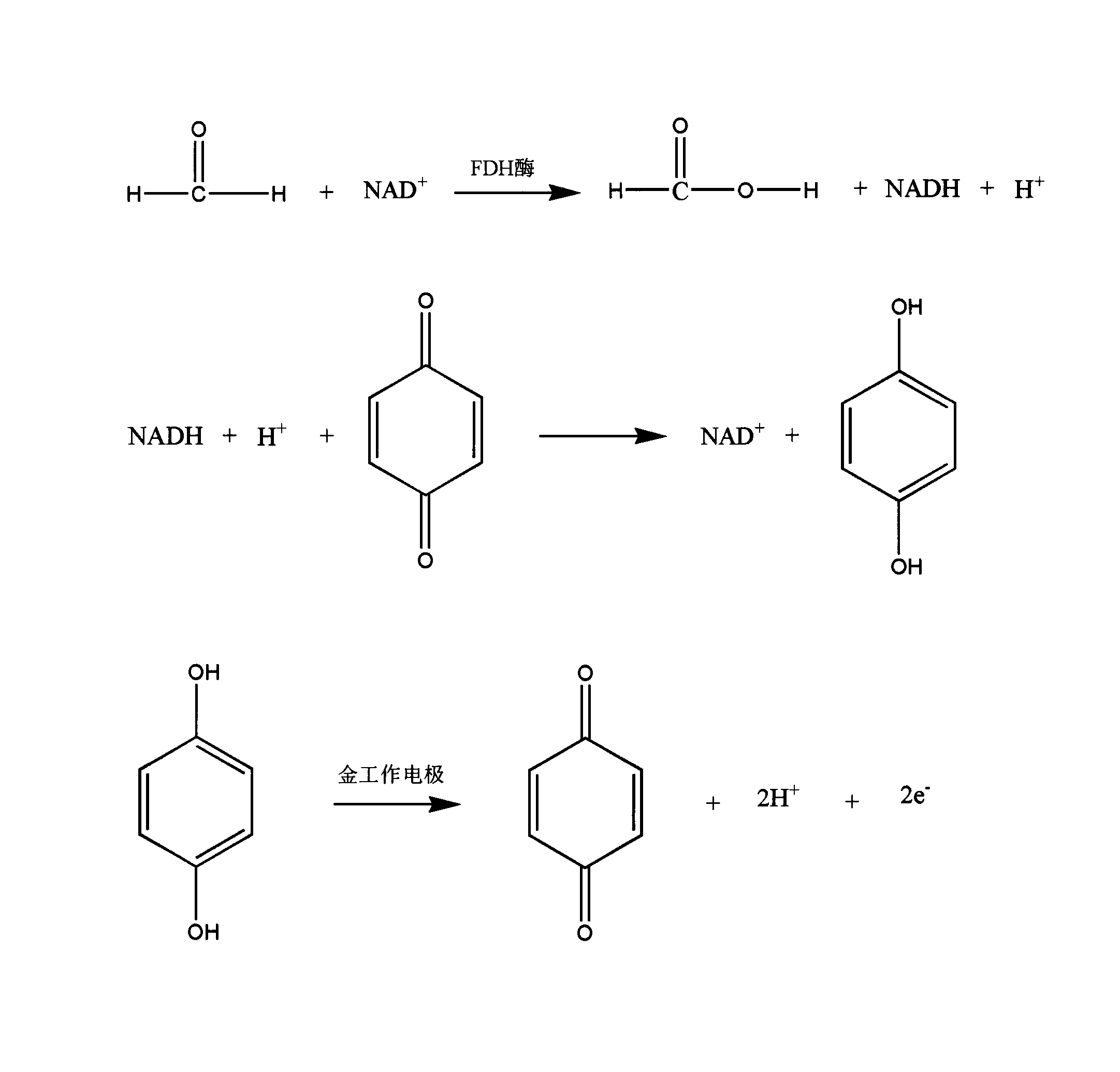

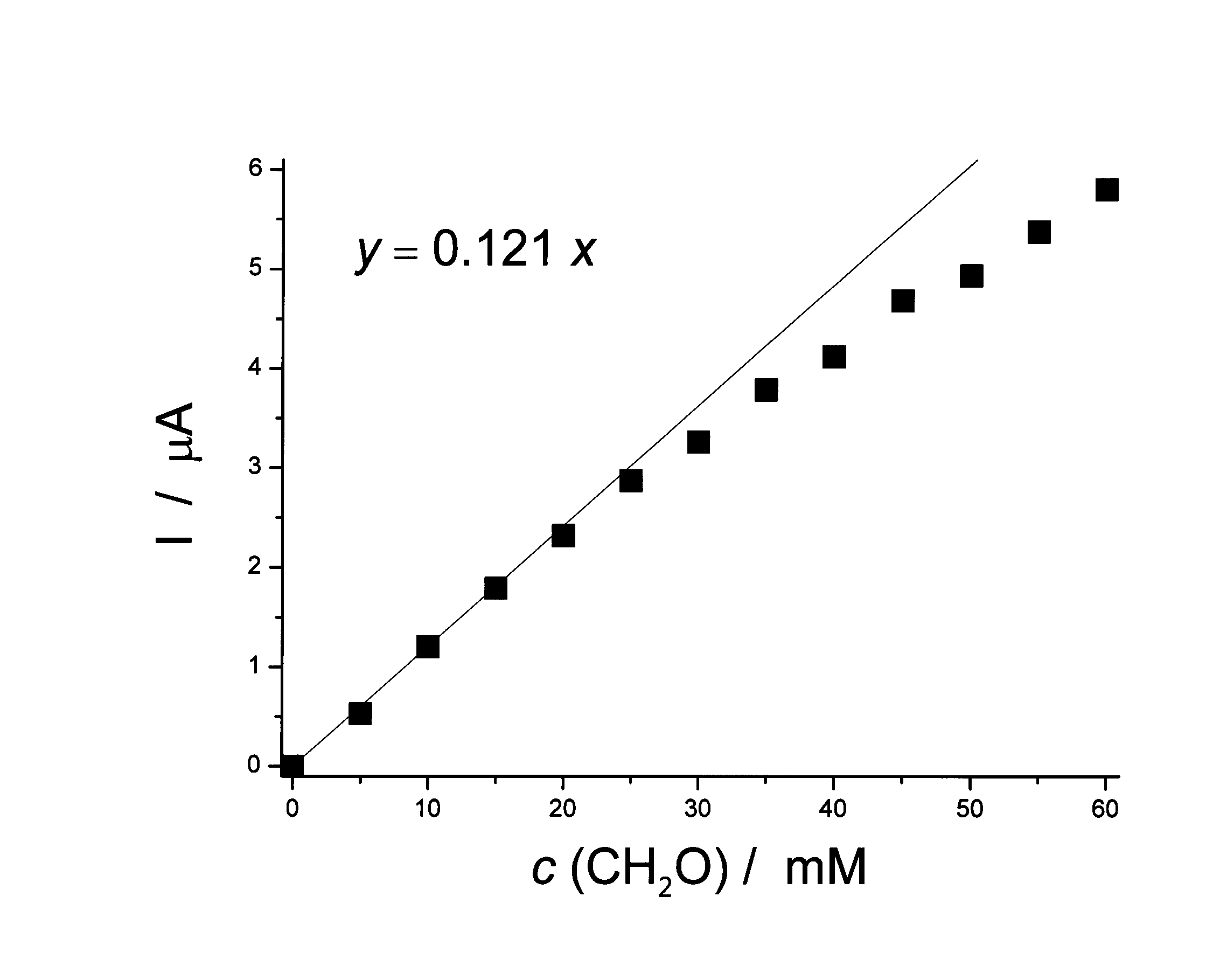

Preparation method of enzyme biosensor for detecting formaldehyde gas

InactiveCN102435652AIncreased sensitivityStrong specificityMaterial analysis by electric/magnetic meansMedical testingBenzoquinone

The invention relates to an enzyme biosensor for detecting a formaldehyde gas. The enzyme biosensor which adopts the high catalytic activity and the high specificity of an enzyme and a microporous polytetrafluoroethylene membrane to acquire is used to detect and monitor the concentration of the trace formaldehyde gas. The formaldehyde gas which permeates the microporous membrane and foamed carbon to enter a sensor reaction chamber transmits electrons in the foamed carbon electrode through NAD<+> and benzoquinone under the catalysis of a formaldehyde dehydrogenase, so the concentration of the formaldehyde gas can be measured through the current detection. The sensor of the invention, which has the characteristics of simple structure, high sensitivity and difficult influence by other gases, is suitable for the medical examination and the continuous monitoring of indoor formaldehyde pollution.

Owner:NANKAI UNIV

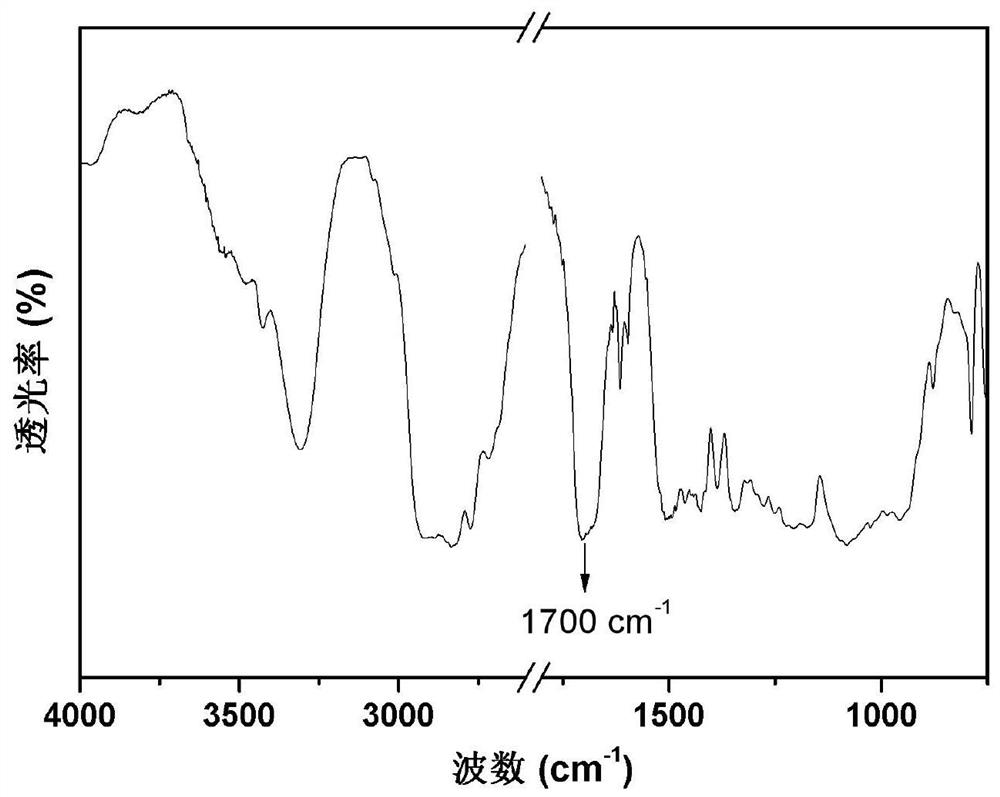

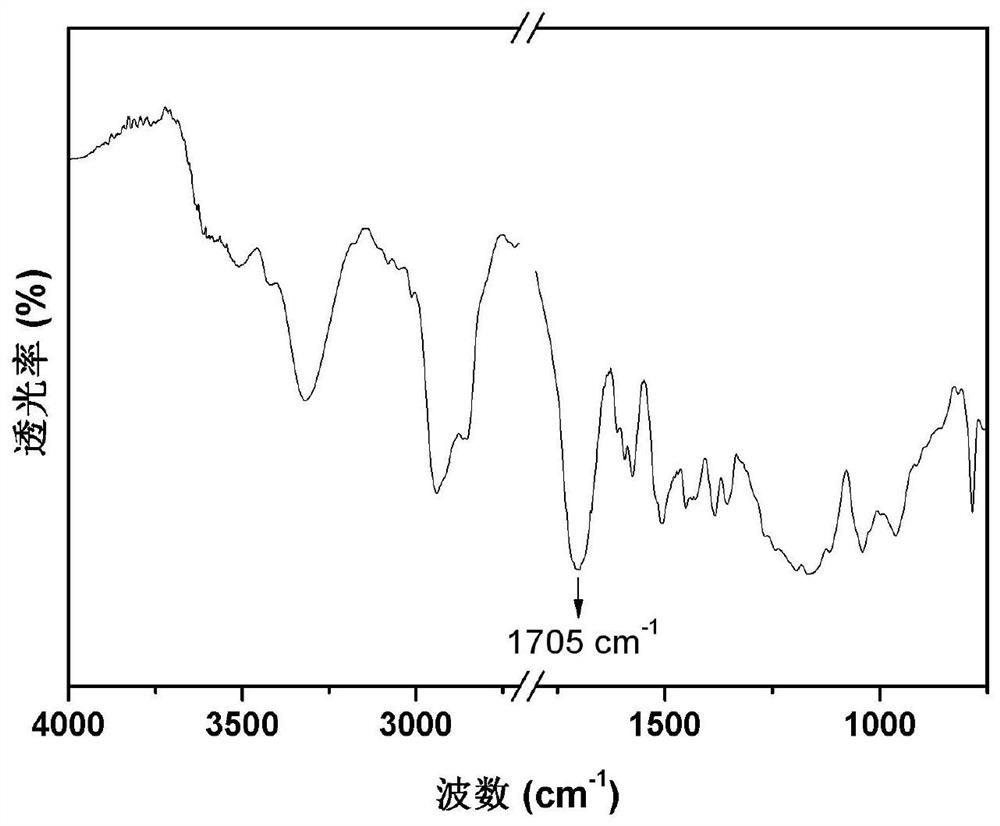

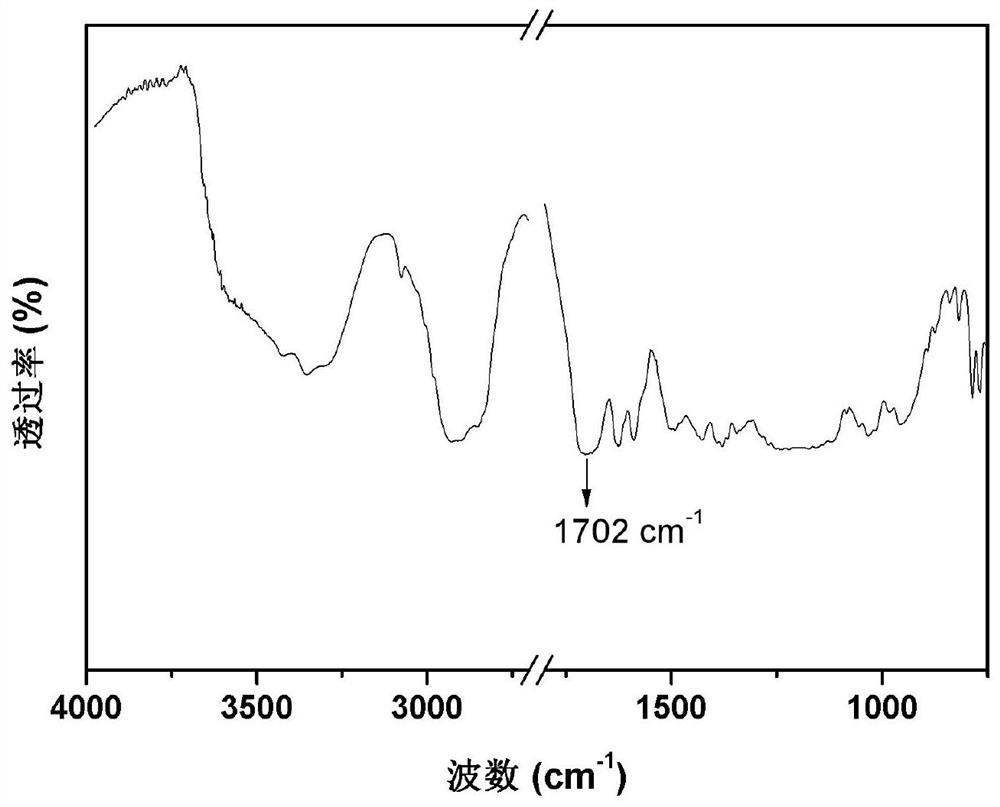

Preparation method for waterproof gas-permeable type textile polyurethane coating agent

InactiveCN108360264AIncrease moisture permeabilityImprove waterproof and breathable performanceFibre treatmentPrepolymerChemistry

The invention relates to a preparation method for a waterproof gas-permeable type textile polyurethane coating agent, and belongs to the technical field of coating agents. According to the technical scheme adopted by the invention, a keratin solution is prepared from feathers, and is polymerized with a polyurethane material; the coating agent is formed after the polyurethane material and keratin are polymerized, keratin is uniformly dispersed inside the material, and a continuous channel is formed in the modified coating layer, so that water vapor penetration is facilitated; the keratin solution can effectively promote the interface between the keratin and polyurethane to have a great number of seams, so that a novel moisture penetrating channel is formed, and therefore, moisture penetrating amount is remarkably improved, and waterproof gas-permeable performance of the coating agent is further improved. Keratin and polyurethane are polymerized, so that keratin loses water under a high-temperature environment, and heat resistance of a composite material is effectively improved; and meanwhile, in a preparation process, the polyurethane material is subjected to self-polymerization reaction, so that number of terminal groups of prepolymer is increased, and effective cross-linking density of the coating is improved, and therefore, a water pressure resistance value of the coating iseffectively increased, and washing distance and toughness of the coating are effectively improved.

Owner:常州五荣化工有限公司

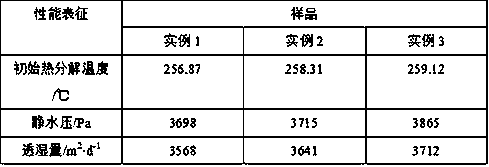

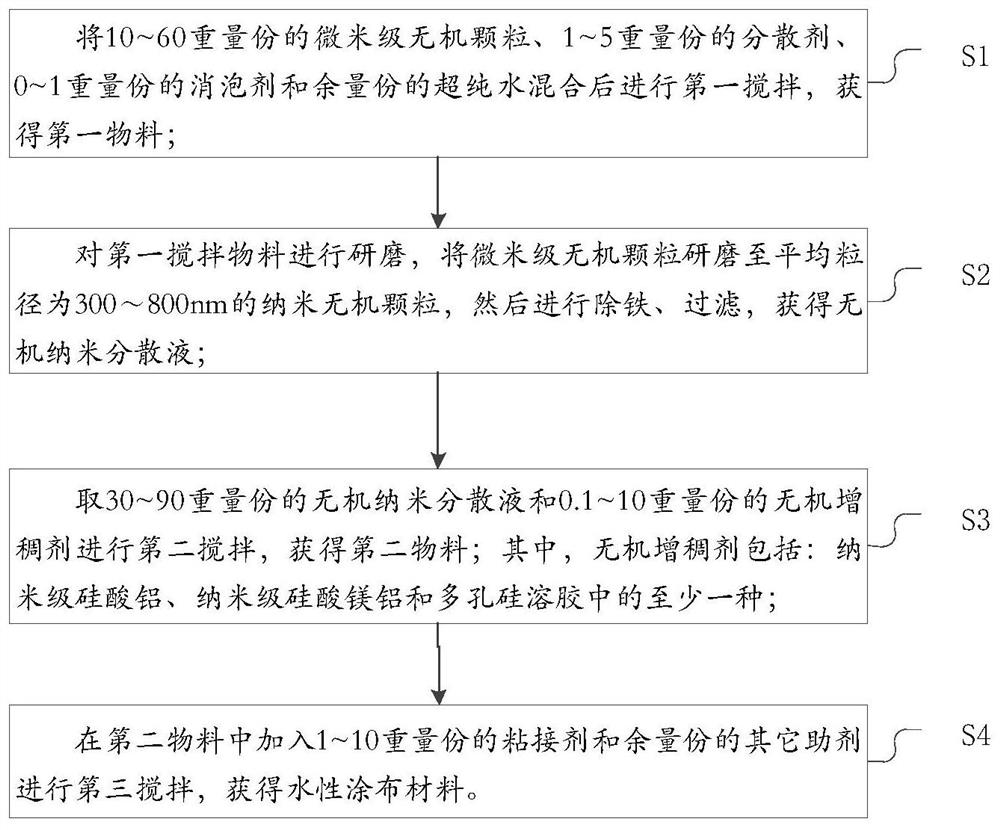

Water-based coating material of lithium battery diaphragm, preparation method and lithium battery

ActiveCN112397847AImprove breathabilityImprove thermal stabilitySecondary cellsCell component detailsAluminum silicatePhysical chemistry

The invention discloses a water-based coating material of a lithium battery diaphragm. The water-based coating material comprises the following components in percentage by weight: 30%-90% of inorganicnano dispersion liquid, 1%-10% of a binder, 0.1%-10% of an inorganic thickener and the balance of other assistants, wherein the inorganic nano dispersion liquid comprises hollow inorganic nano particles; the inorganic thickener comprises at least one of nanoscale aluminum silicate, nanoscale magnesium aluminum silicate and porous silica sol; according to the water-based coating material, in the process of coating the diaphragm and volatilizing the coating, the inorganic thickener and the hollow inorganic nanoparticles can jointly maintain the structural integrity of stacked holes in the diaphragm, so that the air permeability of the diaphragm is improved, and the migration number and the thermal stability of lithium ions are improved; on the other hand, the inorganic thickener is used, sothat the prepared water-based diaphragm coating is more environment-friendly.

Owner:上海大学浙江嘉兴新兴产业研究院

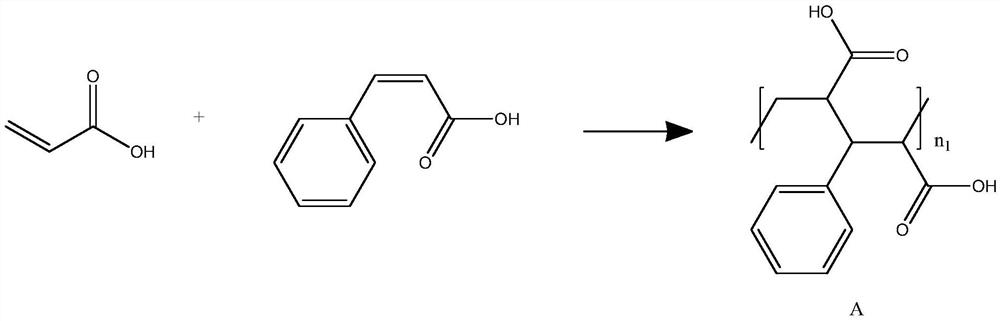

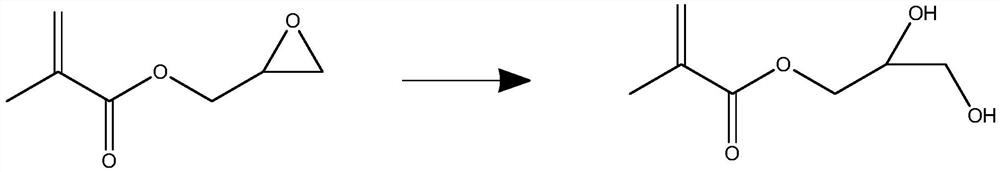

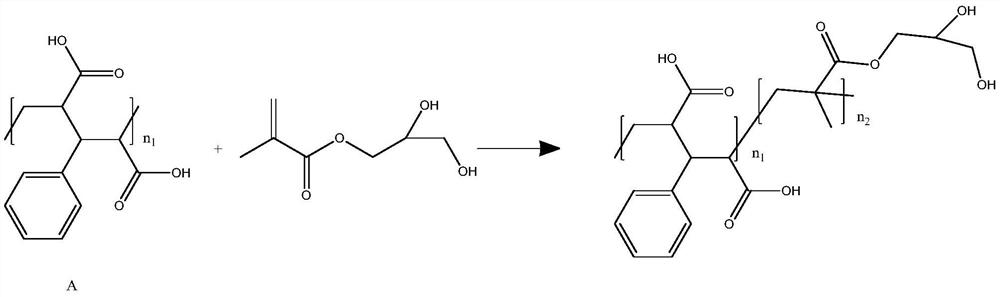

Thixotropic ultraviolet curing adhesive

ActiveCN112126395AHigh transparencyImprove thixotropyNon-macromolecular adhesive additivesModified epoxy resin adhesivesEpoxyMethacrylate

The invention discloses a preparation method and application of a thixotropic ultraviolet adhesive. The ultraviolet curing adhesive is prepared from the following components in parts by mass: 20-40 parts of carbonic ester (methyl) acrylate, 10-35 parts of divinyl epoxy resin, 30-70 parts of reactive monomer, 3-5 parts of hydroxyl-terminated aliphatic hyperbranched polyester, 2-5 parts of initiator, 0.1-0.6 part of defoaming agent and 0.01-0.02 part of polymerization inhibitor. The ultraviolet curing adhesive is high in transparency and good in thixotropic property (the thixotropic index is greater than 1.4), and has very high bonding strength for polycarbonate or polyethylene glycol terephthalate.

Owner:深圳市瑞科美宏电子科技有限公司

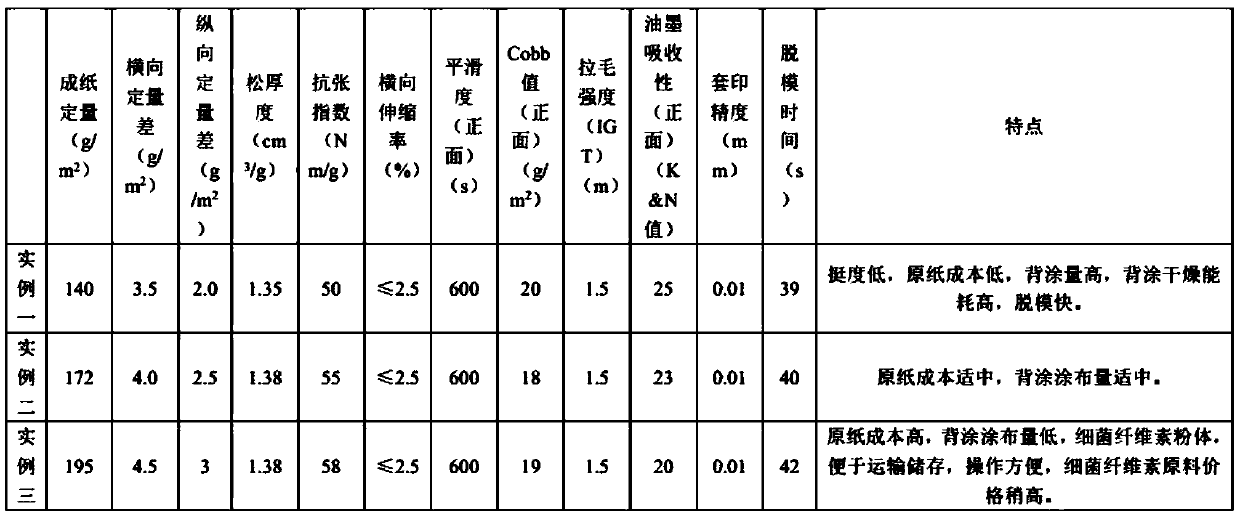

Water transfer paper and preparation method thereof

ActiveCN111472205AAccurate overprintGood printabilitySpecial paperPaper/cardboardSolid contentMaterials science

The invention discloses water transfer paper and a preparation method thereof. The water transfer paper comprises a back coating layer, base paper, a prime coating layer, a water-soluble coating layerand a waterproof coating layer which are distributed layer by layer. Coating of the back coating layer comprises 8-15 parts by weight of a bacterial cellulose wet film; 0.08-0.15 part by weight of hydrogen peroxide, 0.1-0.2 part by weight of sodium hydroxide and 30-40 parts by weight of water, and is prepared by shearing and dispersing at 70-90 DEG C in a high-speed dispersion machine for 30-45 min, adding 40-60 parts by weight of water for dilution, and then sieving the mixture to obtain the back coating, with the solid content of the coating being 2-5%. According to the prepared water transfer paper, on the premise that the water permeation speed of the paper is guaranteed, the back face is coated with the bacterial cellulose glue solution, and the water transfer paper which is stable in size, high in demolding speed and excellent in printing and transferring effect is prepared.

Owner:山东金蔡伦纸业有限公司

Light brick capable of purifying water quality

ActiveCN103132483BFacilitate throughEffectively purify waterDamsSolid waste managementActivated carbonBrick

The invention belongs to the technical field of light bricks and particularly relates to a light brick capable of purifying water quality. The light brick capable of purifying water quality comprises a brick casing and a brick core arranged in the brick casing, wherein the brick core is made of activated carbon, and the brick casing is made of sludge, construction waste, potassium feldspar powder, coal ash and cement. The light brick manufactured by a manufacture method thereof is light in weight, has well water quality purifying function, can maintain long-time ecological balance when applied in river barrage building and enables the water to be clear and green.

Owner:广东春天生态科技集团有限公司

Compound clobetasol propionate lipid composite ointment and preparation method thereof

ActiveCN103349663BSmall and uniform particle sizeFacilitate throughHydroxy compound active ingredientsAerosol deliveryLipid formationTretinoin

The present invention provides a clobetasol propionate and tretinoin ointment agent. According to the present invention, a phospholipid and a positively charged lipid are mainly adopted to wrap drugs to prepare a lipid complex, wherein the positively charged lipid complex can concurrently wrap two drugs, encapsulation efficiency is high, and leakage is not easily generated; with the lipid complex, drug absorption can be promoted, and drug retention in skin can be increased; the multi-component low co-melting system is adopted to prepare the solid dispersion, such that the composite antioxidant component in the formula is uniformly dispersed in the same system; an oil phase matrix and an emulsifying agent are added so as to further prepare into a cream agent or an ointment agent in one step; and the preparation has characteristics of good emulsifying uniformity and high stability, and can be used for treatment of psoriasis, chronic dermatitis and eczema, skin papule type amyloidopathia, lichen planus, and non-atopic dermatitis.

Owner:JIANGSU SEMPOLL PHARMA

Building sunscreen heat insulation coating and preparation method thereof

ActiveCN113372776AImprove dispersion stabilityPromote the development of high-grade green buildingsEpoxy resin coatingsEpoxyNonlinear optical crystal

The invention discloses a building sunscreen heat insulation coating and a preparation method thereof. The preparation method comprises the following steps: mixing waterborne acrylic resin, modified silicon dioxide sol, zinc phosphate, organic fluorine epoxy resin and organic silicon resin to obtain a blended material, adding the blended material into a stirring tank, uniformly stirring, and filtering. Boric acid microparticles and an inorganic filler are doped into a SiO2 sol precursor, so defects in the nonlinear optical crystal are filled, the infrared radiation performance is further regulated and controlled, and the function of enhancing the infrared radiation performance of the atmospheric window wave band is achieved; and a dispersing agent is added the molecular chain of the dispersing agent can be completely expanded in an aqueous solution, and forms a surface adsorption layer with a certain thickness on the surfaces of SiO2 aerogel particles, and a steric hindrance effect is generated, so that the aims of promoting the development of high-grade green buildings and improving the dispersion stability of a SiO2 aerogel system are fulfilled.

Owner:JIANGSU MIRAFUL NANO MATERIAL CO LTD +1

Compound clobetasol propionate lipid composite ointment and preparation method thereof

ActiveCN103349663ASmall and uniform particle sizeFacilitate throughHydroxy compound active ingredientsAerosol deliveryMedicineOil phase

The present invention provides a clobetasol propionate and tretinoin ointment agent. According to the present invention, a phospholipid and a positively charged lipid are mainly adopted to wrap drugs to prepare a lipid complex, wherein the positively charged lipid complex can concurrently wrap two drugs, encapsulation efficiency is high, and leakage is not easily generated; with the lipid complex, drug absorption can be promoted, and drug retention in skin can be increased; the multi-component low co-melting system is adopted to prepare the solid dispersion, such that the composite antioxidant component in the formula is uniformly dispersed in the same system; an oil phase matrix and an emulsifying agent are added so as to further prepare into a cream agent or an ointment agent in one step; and the preparation has characteristics of good emulsifying uniformity and high stability, and can be used for treatment of psoriasis, chronic dermatitis and eczema, skin papule type amyloidopathia, lichen planus, and non-atopic dermatitis.

Owner:JIANGSU SEMPOLL PHARMA

Fat emulsion injection of 'Xingnaojing' and its preparing process

InactiveCN1279892CHigh purityFully extractedHydroxy compound active ingredientsMammal material medical ingredientsHas active ingredientEmulsion

Disclosed is a fat emulsion injection of 'Xingnaojing' and its preparing process, which comprises using supercritical extraction technology and macroscopic adsorption resin technology for isolating and purifying the water soluble and fat soluble parts in the medicinal materials including musk, cape jasmine, and curcuma root, finally utilizing emulsion technology to obtain the end product.

Owner:JIANGSU QINGJIANG PHARMA

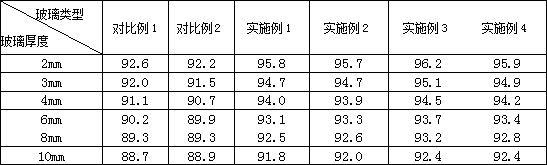

Solar cell glass

The invention discloses solar cell glass. The solar cell glass is prepared from, in parts by weight, 60-80 parts of a glass substrate, 0.5-1.5 parts of an activator, 1-3 parts of a sensitizer and 5-15parts of an oxidant, wherein the glass substrate is prepared from, in parts by weight, 72-79 parts of SiO2, 5-14 parts of CaO, 10-16 parts of Na2O, 1.5-6 parts of MgO and 0.5-3 parts of Al2O3. According to the solar cell glass, since a small quantity of the activator is added, the efficiency of energy transfer of the solar cell glass can be increased, the heat absorption of the solar cell glass can be reduced, and the light transmittance of the solar cell glass can be improved; meanwhile, through the addition of a small quantity of the sensitizer, the solar cell glass can be more sensitive tolight, so that light transmission through glass is facilitated, and the light transmittance of the solar cell glass is increased; the solar cell glass can be applied to the field of manufacture of solar cell glass.

Owner:GUANGXI CHAOXING SOLAR ENERGY TECH

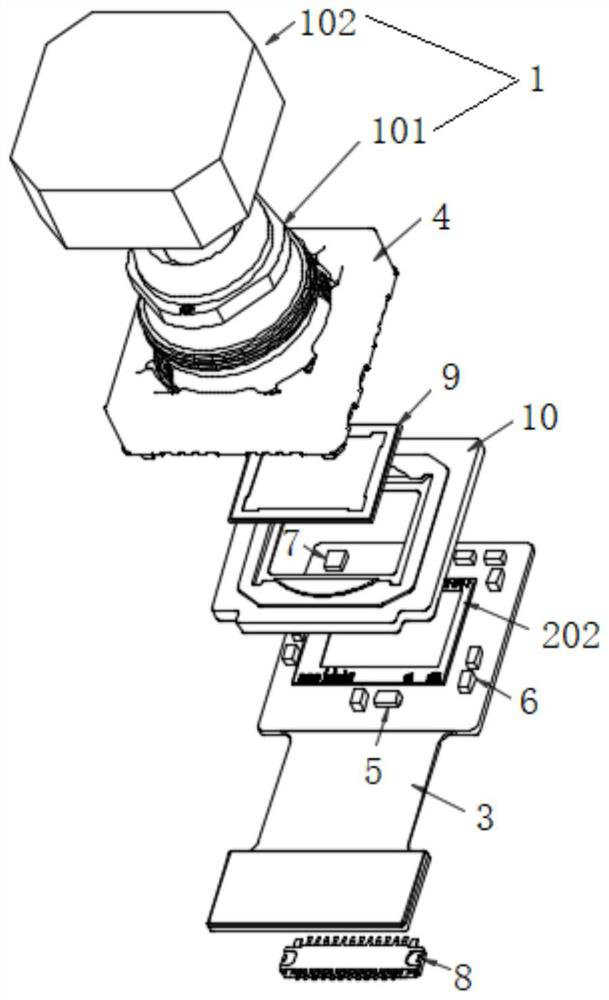

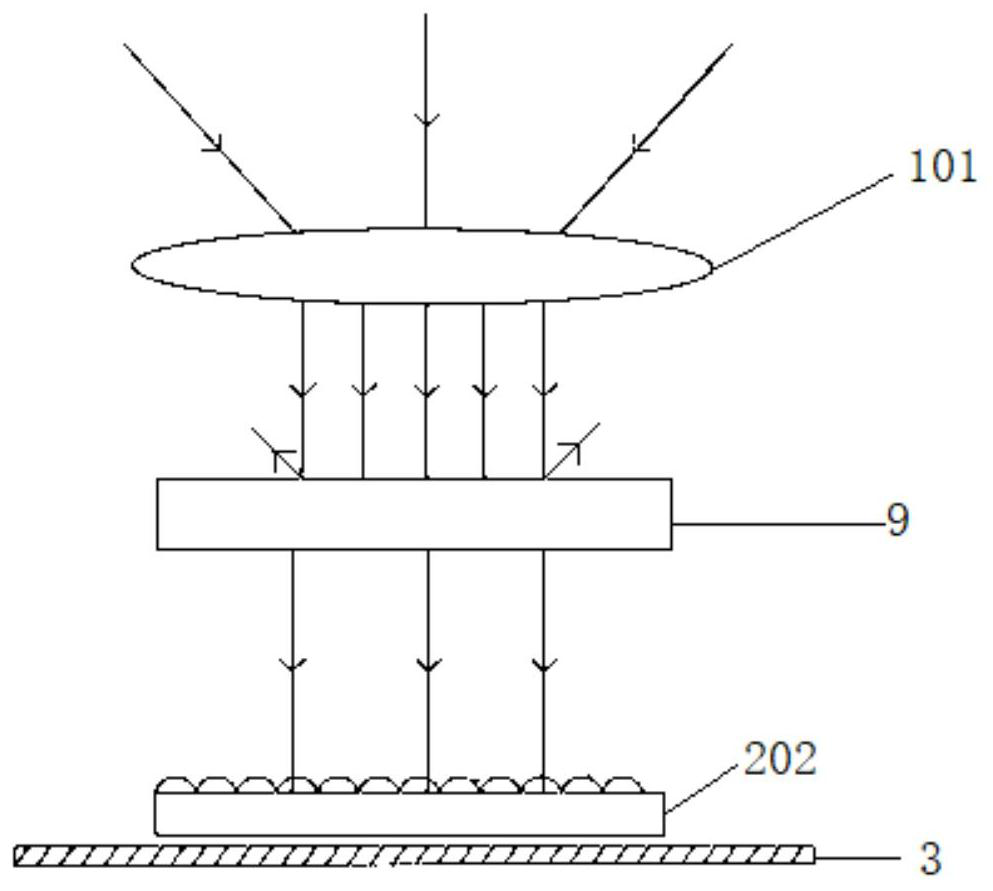

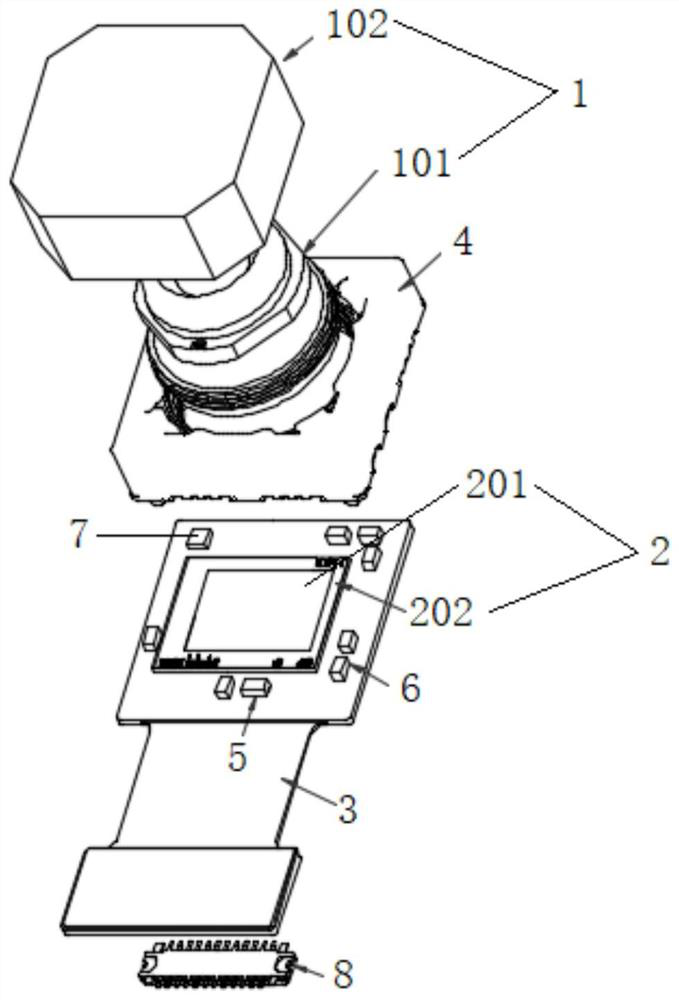

Camera module and electronic equipment

PendingCN112492235AIncrease photosensitivityImprove the shooting effectTelevision system detailsColor television detailsInfraredEngineering

The invention discloses a camera module and electronic equipment. The camera module comprises a camera assembly, a sensor and a circuit board; the camera assembly comprises a camera structure; the sensor comprises a photosensitive chip and an infrared optical structure arranged on the surface of the photosensitive chip; the sensor is electrically connected with the circuit board. According to theapplication, the infrared optical structure is arranged on the surface of the photosensitive chip, and an IR optical filter is canceled, so that the space can be saved due to the structural design, and the size of the whole camera module in the height direction can be reduced; moreover, the infrared optical structure is arranged on the photosensitive chip, so that the photosensitive effect of thephotosensitive chip can be greatly improved, and the shooting effect of the camera module can be further improved.

Owner:VIVO MOBILE COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com