Flexible thin film solar cell and packaging method thereof

A technology of solar cells and flexible films, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve problems such as battery weight, reduce quality, improve photoelectric conversion efficiency, and facilitate transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] a. According to the process requirements, the cutting size is 35×35cm 2 Teflon plastic film and EVA cross-linked layer, use 95% alcohol to clean the surface of Teflon plastic film;

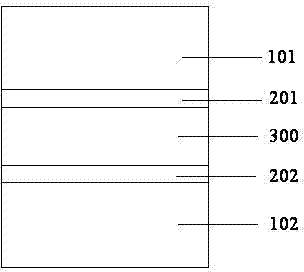

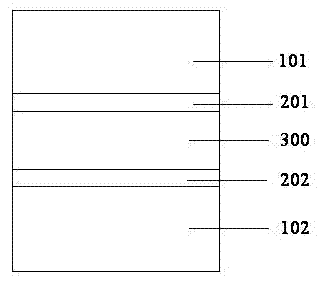

[0055] b. According to figure 1 In the five-layer structure shown, one layer of Teflon plastic film and one layer of EVA cross-linked layer are arranged in sequence;

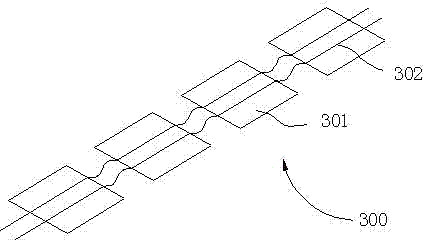

[0056] c. Use a welding machine to connect the 3 unit cells together with a welding strip in the order of positive and negative poles;

[0057] d. According to the process requirements, arrange the battery strings welded in step c on the EVA cross-linked layer completed in step b in turn, and connect the positive and negative electrodes of the solar cell strings in sequence with welding tape through a welding machine to lead out the positive and negative electrodes pole terminal;

[0058] e. Arrange one deck of EVA cross-linked layer and one deck of Teflon plastic film successively on the solar cell string that step d is f...

Embodiment 2

[0063] According to the method in Example 1, except that the following steps are modified, other steps are identical.

[0064] f. Put the 5-layer structure completed in step e into a fully automatic laminator, vacuumize for 10 minutes, heat at 125°C, and laminate for 35 minutes.

[0065]

Embodiment 3

[0067] According to the method in Example 1, except that the following steps are modified, other steps are identical.

[0068] f. Put the 5-layer structure completed in step e into a fully automatic laminator, vacuumize for 15 minutes, heat at 130°C, and laminate for 30 minutes.

[0069]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com