Preparation method for waterproof gas-permeable type textile polyurethane coating agent

A polyurethane coating and air-permeable technology, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of fabric moisture permeability decline, etc., and achieve the effect of increasing effective crosslinking density, improving heat resistance, and increasing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

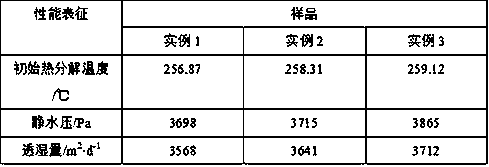

example 1

[0018] In parts by weight, weigh 45 parts of deionized water, 10 parts of thioglycolic acid, 6 parts of urea, 3 parts of sodium lauryl sulfate, and 6 parts of feathers in an Erlenmeyer flask, stir and mix and place at room temperature Let stand for 3, filter and collect the filtrate to obtain the modified keratin solution; weigh 25 parts of itaconic acid, 10 parts of N-isopropylacrylamide, 3 parts of modified keratin solution, 16 parts by weight respectively One part of N,N-methylenebisacrylamide and 3 parts of ammonium persulfate were placed in a three-necked flask, stirred and mixed, and the air was vented with nitrogen, and the rate of nitrogen gas was controlled to be 25mL / min. Heating in a water bath at 45°C for 20 hours, standing and cooling to room temperature to obtain a gel solution; in parts by weight, weigh 45 parts of 2,4-toluene diisocyanate, 10 parts of polyethylene glycol, 6 parts of polypropylene glycol and 15 parts of The polyacrylonitrile-dimethylformamide so...

example 2

[0020] In parts by weight, weigh 47 parts of deionized water, 12 parts of thioglycolic acid, 7 parts of urea, 4 parts of sodium lauryl sulfate, and 7 parts of feathers in an Erlenmeyer flask, stir and mix and place at room temperature Let stand for 4 hours, filter and collect the filtrate to obtain a modified keratin solution; weigh 27 parts of itaconic acid, 12 parts of N-isopropylacrylamide, 4 parts of modified keratin solution, and 17 parts by weight respectively. One part of N,N-methylenebisacrylamide and 4 parts of ammonium persulfate were placed in a three-necked flask, stirred and mixed, and the air was vented with nitrogen, and the rate of nitrogen gas was controlled to be 27mL / min. Under a nitrogen atmosphere, the three-necked flask was placed Heated in a water bath at 47°C for 22 hours, allowed to stand and cooled to room temperature to obtain a gel solution; weighed 47 parts of 2,4-toluene diisocyanate, 12 parts of polyethylene glycol, 7 parts of polypropylene glycol...

example 3

[0022] In parts by weight, weigh 50 parts of deionized water, 15 parts of thioglycolic acid, 8 parts of urea, 5 parts of sodium lauryl sulfate, and 8 parts of feathers in an Erlenmeyer flask, stir and mix and place at room temperature Let stand for 5 hours, filter and collect the filtrate to obtain a modified keratin solution; weigh 30 parts of itaconic acid, 15 parts of N-isopropylacrylamide, 5 parts of modified keratin solution, and 18 parts by weight respectively. One part of N,N-methylenebisacrylamide and 5 parts of ammonium persulfate were placed in a three-necked flask, stirred and mixed, and the air was vented with nitrogen gas, and the rate of nitrogen gas was controlled to be 30mL / min. Under a nitrogen atmosphere, the three-necked flask was placed Heating in a water bath at 55°C for 24 hours, standing and cooling to room temperature to obtain a gel solution; in parts by weight, weigh 50 parts of 2,4-toluene diisocyanate, 15 parts of polyethylene glycol, 8 parts of poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com