Preparation method of 3D ordered macroporous polyaniline (OM PANI)/TiO2 composite photocatalytic material and application thereof

A titanium dioxide, three-dimensional ordered technology, applied in the field of photocatalytic materials, can solve the problems of difficult recovery, easy agglomeration, reduction of photocatalytic efficiency, etc., and achieve the effects of easy sedimentation, high catalytic activity, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0040] A method for preparing a three-dimensional ordered macroporous polyaniline / titanium dioxide composite material, comprising the steps of:

[0041] (1) Preparation of three-dimensional ordered macroporous titanium dioxide material

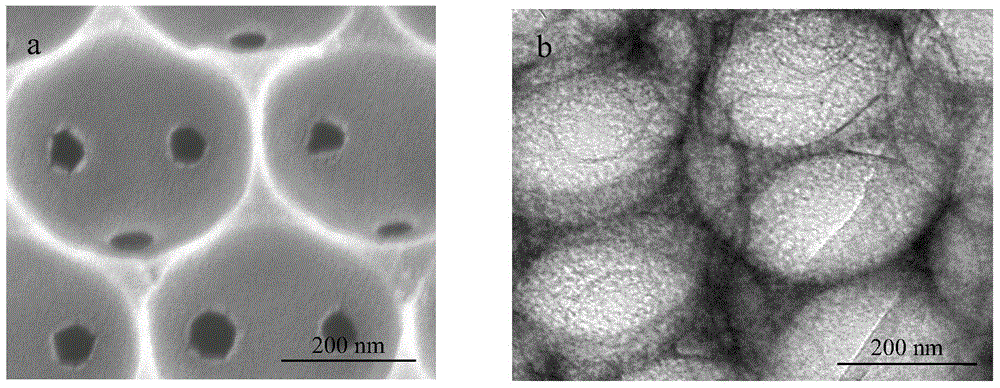

[0042] First, polystyrene (PS) microspheres were synthesized by soap-free emulsion polymerization using styrene as a monomer, and assembled into PS colloidal crystal templates by natural deposition.

[0043] Then use tetrabutyl titanate as titanium source, mix with ethanol, hydrochloric acid, glacial acetic acid and distilled water to make transparent TiO 2 Sol solution precursor. Soak the PS colloidal template in TiO 2 Sol in the sol for 30 minutes, then remove excess sol by suction filtration, dry at 75°C for 2 hours, repeat the above filling process several times. Finally, in a tubular heating furnace, slowly heat up the PS template filled with the precursor to 300°C for 2-4 hours, remove the PS template by oxidative decomposition proces...

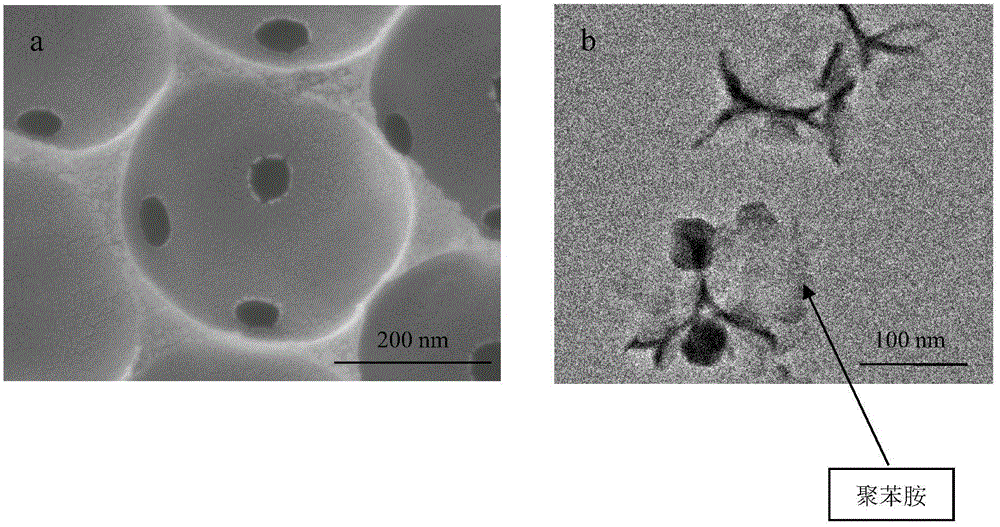

preparation Embodiment 2

[0046] A method for preparing a three-dimensional ordered macroporous polyaniline / titanium dioxide composite material, the preparation of a three-dimensional ordered macroporous titanium dioxide material is the same as in Example 1, and the difference from Example 1 is the preparation of a three-dimensional ordered macroporous polyaniline / titanium dioxide composite material The method comprises the following steps: A. Dip and disperse 7 g of the prepared three-dimensional ordered macroporous titanium dioxide material in 20 ml of hydrochloric acid solution containing 0.25 ml of aniline monomer, and ultrasonically vibrate for 15 min; B. place the reaction system in step (A) on ice in the bath, and slowly dropwise add the monomer initiator ammonium persulfate solution with a concentration of 0.7%, and the reaction system continues to react for 2.5 hours after the dropwise addition; ; D. Dry the washed sample at a low temperature of 70° C. to obtain a three-dimensional ordered macr...

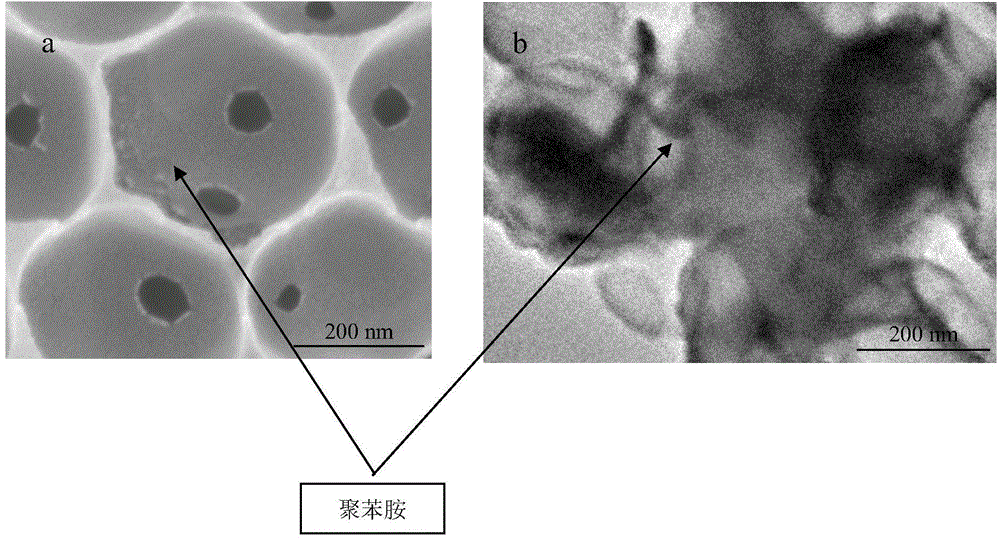

preparation Embodiment 3

[0048] A method for preparing a three-dimensional ordered macroporous polyaniline / titanium dioxide composite material, the preparation of a three-dimensional ordered macroporous titanium dioxide material is the same as in Example 1, and the difference from Example 1 is the preparation of a three-dimensional ordered macroporous polyaniline / titanium dioxide composite material The method comprises the following steps: A, immersing and dispersing 10 g of the prepared three-dimensional ordered macroporous titanium dioxide material in 20 ml of hydrochloric acid solution containing 0.5 ml of aniline monomer, and ultrasonically vibrating for 20 min; B, placing the reaction system in step (A) on ice in the bath, and slowly add the monomer initiator ammonium persulfate solution with a concentration of 1%, and the reaction system continues to react for 5 hours after the addition; ; D. Drying the washed sample at a low temperature of 80° C. to obtain a three-dimensional ordered macroporous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com