Finishing method of waterproof and moisture-permeable clothing fabric

A waterproof and moisture-permeable, clothing technology, applied in the field of textiles, can solve the problems that the coating is easy to wash off, the coating is difficult to obtain continuous and uniform moisture-permeable micropores, etc., and achieves the effect of favorable moisture-permeability and good waterproofness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

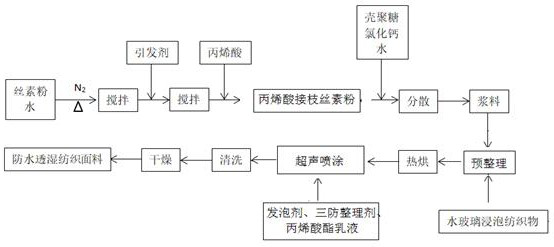

Method used

Image

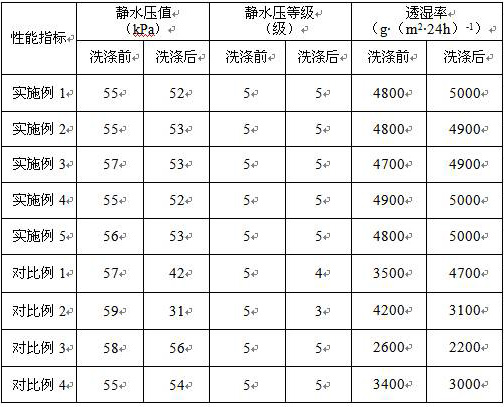

Examples

Embodiment 1

[0037] (1) Add 3 kg of silk fibroin powder with a particle size of 5 μm into 18 kg of water, disperse and stir evenly, then pass in nitrogen gas and gradually raise the temperature to 65°C, then add 0.02 kg of potassium persulfate and stir for 8 minutes, then add 1 kg of acrylic acid and stir for 1.5 hours at a low speed , making the acrylic acid graft modified silk fibroin powder to obtain a graft modified silk fibroin dispersion;

[0038] (2) Add 2kg of chitosan, 1.5kg of calcium chloride, and 3kg of deionized water to 100kg of grafted modified silk fibroin dispersion, and disperse evenly to obtain a slurry;

[0039] (3) Immerse the polyester fiber fabric in water glass liquid with a mass concentration of 40%, with a bath ratio of 1:60, soak for 12.5 minutes, and then perform rolling to remove excess water glass liquid to obtain pretreated textiles;

[0040] (4) The pretreated textiles were dipped and tied twice through the slurry, and the excess rate was 72.5%, and then the...

Embodiment 2

[0043] (1) Add 2.5kg of silk fibroin powder with a particle size of 2μm into 19kg of water to disperse and stir evenly, then pass in nitrogen and gradually raise the temperature to 62°C, then add 0.015kg of potassium persulfate and stir for 6 minutes, then add 0.9kg of acrylic acid and stir at a low speed for reaction 1h, make acrylic acid graft modified silk fibroin powder obtain graft modified silk fibroin dispersion liquid;

[0044] (2) Add 1.5kg of chitosan, 1.2kg of calcium chloride, and 2kg of deionized water to 100kg of grafted modified silk fibroin dispersion, and disperse evenly to obtain a slurry;

[0045] (3) Immerse the polyester fiber fabric in water glass liquid with a mass concentration of 38%, with a bath ratio of 1:55, soak for 14 minutes, and then perform roll pressing to remove excess water glass liquid to obtain pretreated textiles;

[0046] (4) The pretreated textile was dipped and tied twice in the slurry, and the excess rate was 71%, and then the fabric ...

Embodiment 3

[0049] (1) Add 3.5kg of silk fibroin powder with a particle size of 8μm into 17kg of water to disperse and stir evenly, then pass in nitrogen and gradually raise the temperature to 68°C, then add 0.025kg of potassium persulfate and stir for 9 minutes, then add 1.1kg of acrylic acid and stir at a low speed for reaction 2h, make acrylic acid graft modified silk fibroin powder obtain graft modified silk fibroin dispersion liquid;

[0050] (2) Add 2.5 kg of chitosan, 1.8 kg of calcium chloride, and 4 kg of deionized water to 100 kg of grafted modified silk fibroin dispersion, and disperse evenly to obtain a slurry;

[0051] (3) Immerse the polyester fiber fabric in water glass liquid with a mass concentration of 42%, the bath ratio is 1:65, soak for 14 minutes, and then carry out rolling to remove excess water glass liquid to obtain pretreated textiles;

[0052] (4) The pretreated textile is dipped and tied twice through the pulp, and the excess rate is 74%, and then the fabric af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com