Preparation method for flexible and bendable aluminum ion battery

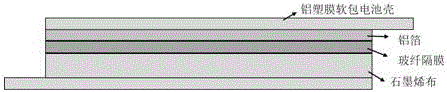

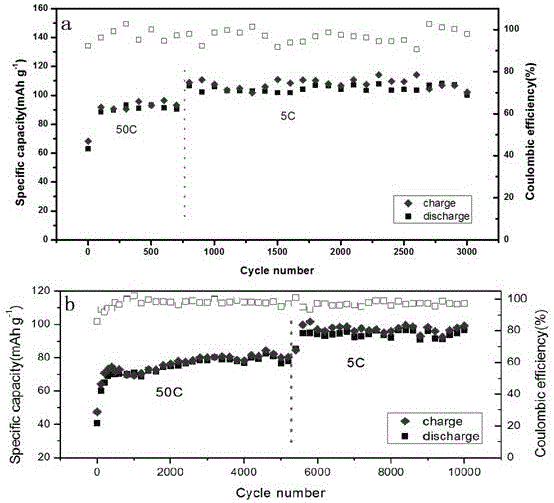

An aluminum-ion battery, bending technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of being unable to meet wearable portable devices, not having mass production characteristics, not being bendable, etc., and achieving fast charging and discharging characteristics, rapid charge and discharge performance, and the effect that is beneficial to adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

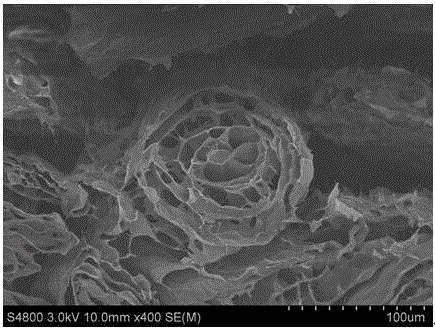

[0029] 1) Add 1 part by weight of graphene oxide to 1000 parts by weight of deionized water, and treat it in a 20Hz ultrasonic bath for 1 hour to obtain a concentration of 1 mg • mL -1 Graphene oxide dispersion;

[0030] 2) Extrude the graphene oxide dispersion liquid from a spinning head with a diameter of 100 microns into a rotating coagulation bath. The formula of the coagulation bath is: the volume ratio of ethanol to water is 3:1, and the mass fraction of calcium chloride is 5 %. The speed of the coagulation bath is 1000RPM;

[0031] 3) Collect the coagulation bath by filtering it with a filter screen, and the graphene oxide fibers (fiber length is 8-10 cm) in the coagulation bath are overlapped on the filter screen to form a graphene oxide cloth. Graphene oxide was dried at room temperature for 2 hours and then lyophilized, and then the lyophilized graphene oxide was placed in a 500mL airtight container, and 5mL of hydrazine hydrate aqueous solution with a concentratio...

Embodiment 2

[0036] 1) Add 5 parts by weight of graphene oxide to 1000 parts by weight of N,N-dimethylformamide, and treat it in a 50Hz ultrasonic bath for 0.5 hours to obtain a concentration of 5 mg·mL -1 Graphene oxide dispersion;

[0037] 2) The graphene oxide dispersion is extruded into a rotating coagulation bath through a spinning head with a diameter of 130 microns, and the coagulation bath is ethyl acetate solution. The rotation speed of the coagulation bath is 700RPM;

[0038]3) Collect the coagulation bath by filtering it with a filter screen, and the graphene oxide fibers (fiber length is about 10 cm) in the coagulation bath are overlapped on the filter screen to form a graphene oxide cloth. After the graphene oxide was dried at room temperature for 5 hours, it was dried in an oven at 60°C to remove the solvent. Arrange the dried graphene oxide in a nitrogen atmosphere, heat it to 2800°C in a graphitization furnace and keep it for one hour to obtain a graphene cloth with high ...

Embodiment 3

[0043] 1) Add 1 part by weight of graphene oxide and 1 part by weight of ammonium bicarbonate inorganic salt to 1000 parts by weight of deionized water, and treat it in a 20Hz ultrasonic bath for 1 hour to obtain a concentration of 1 mg·mL -1 Graphene oxide dispersion;

[0044] 2) Extrude the graphene oxide dispersion liquid from a spinning head with a diameter of 150 microns into a rotating coagulation bath. The formula of the coagulation bath is: the volume ratio of ethanol to water is 3:1, and the mass fraction of calcium chloride is 5 %. The speed of the coagulation bath is 1000RPM;

[0045] 3) Collect the coagulation bath by filtering it with a filter screen, and the graphene oxide fibers (fiber length is 8-10 cm) in the coagulation bath are overlapped on the filter screen to form a graphene oxide cloth. Arrange the graphene oxide at room temperature to dry for 2 hours and then freeze-dry, then arrange the freeze-dried graphene oxide in a 500mL airtight container, drop ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com