Phosphorus-based organic matter intercalation structure selective infrared absorption material, preparation method and application thereof

A technology of infrared absorption and organic matter, which is applied in the field of selective infrared absorption materials with phosphine-based organic matter intercalation structure and its preparation, can solve the problems of limited application and absorption defects, and achieve the effects of easy preparation, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

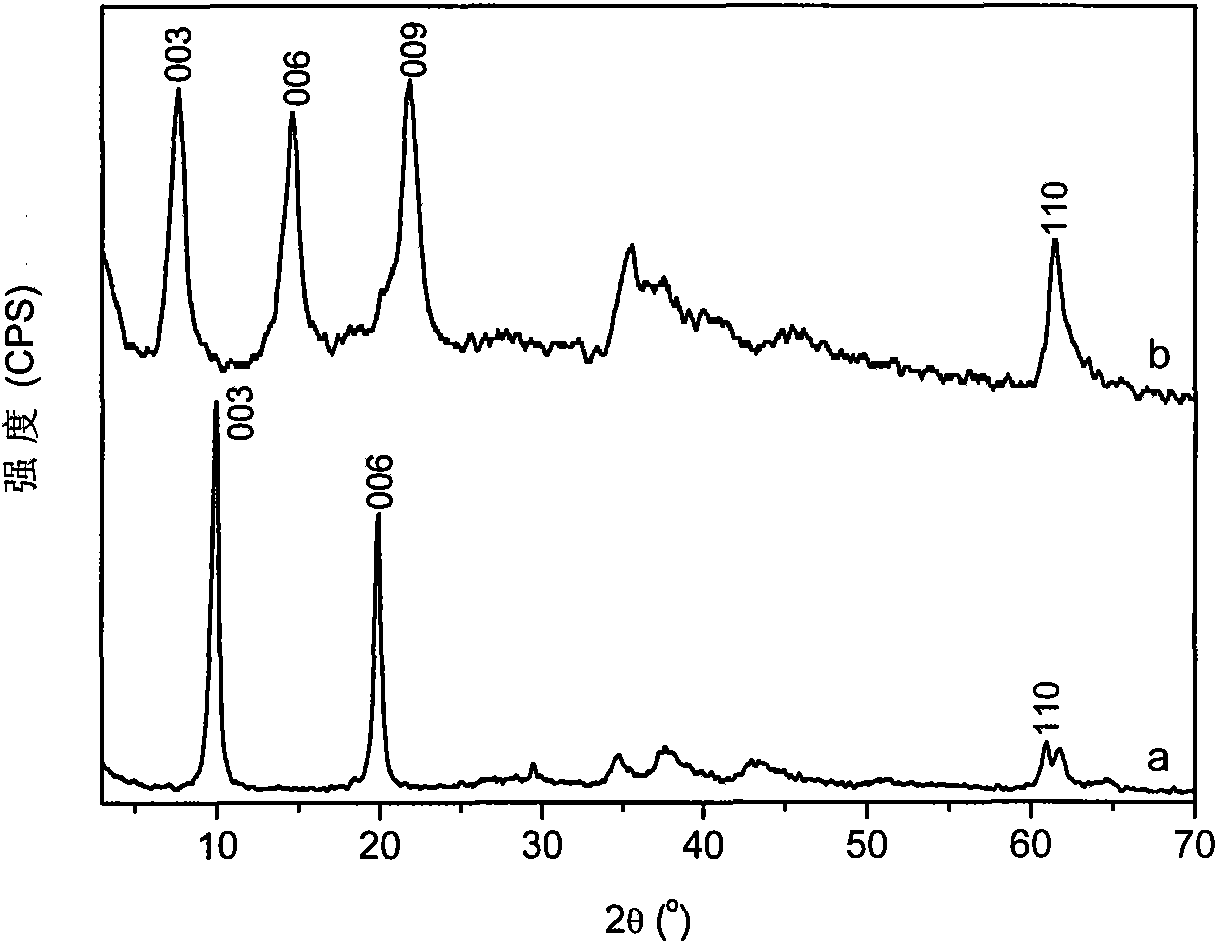

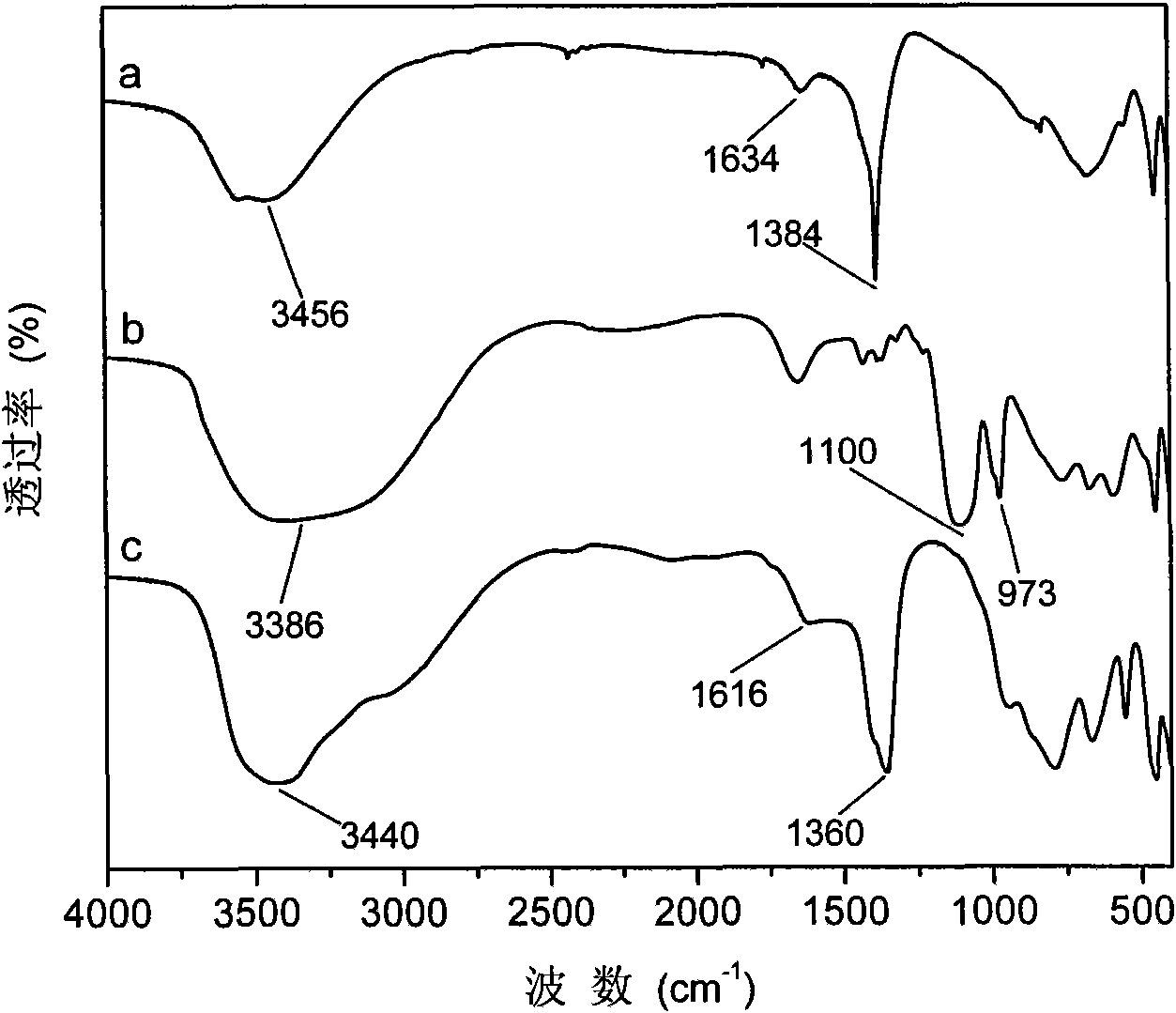

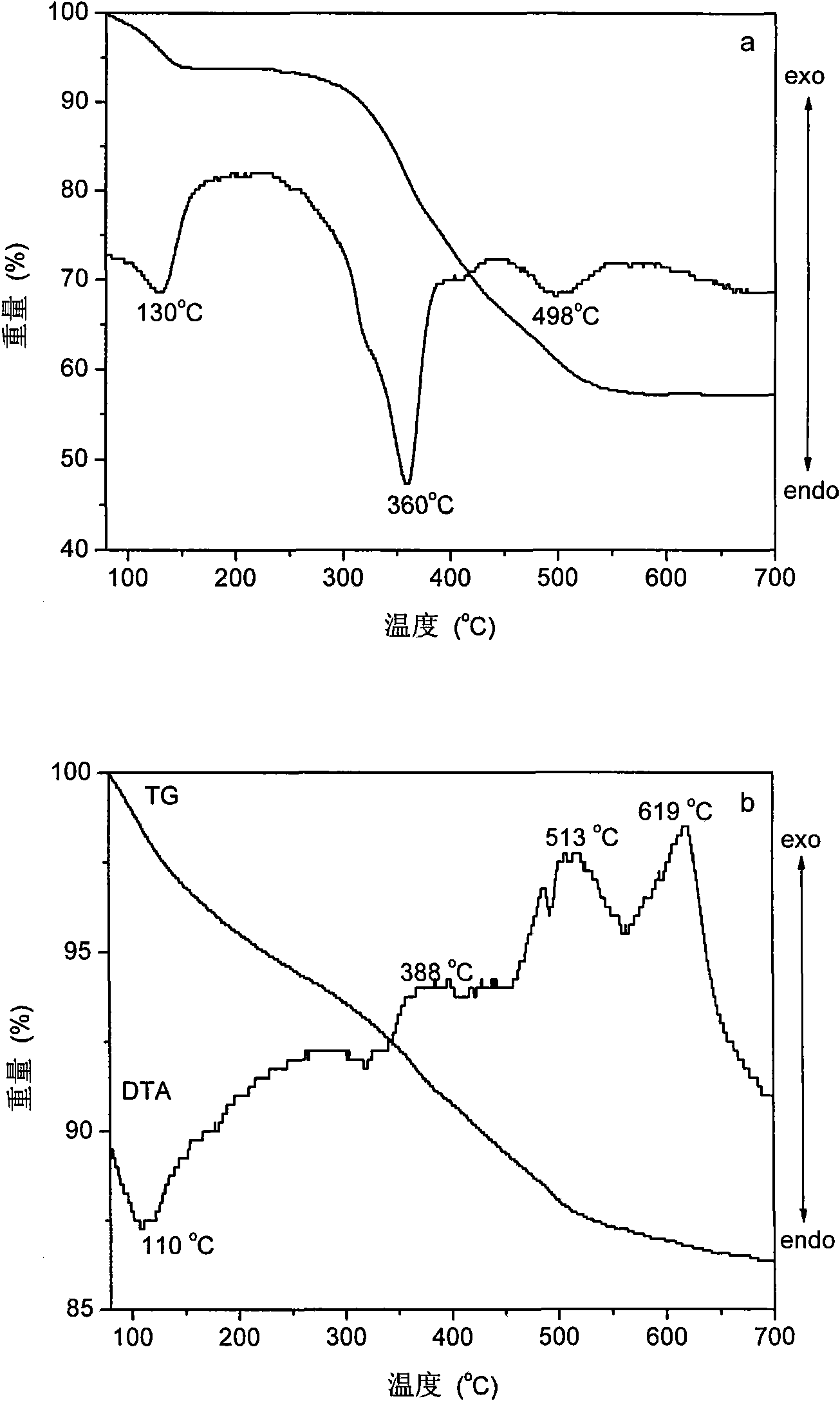

Embodiment 1

[0037] Step A: 45.0g (0.12mol) of solid Al(NO 3 ) 3 9H 2 O and 61.5g (0.24mol) of solid Mg(NO 3 ) 2 ·6H 2 O dissolves in removing CO 2 Prepare 300ml of mixed salt solution A in deionized water; and dissolve 28.8g (0.72mol) of solid NaOH in deionized water to prepare 300ml of alkali solution B. Rapidly nucleate the alkali solution and the salt solution in a fully back-mixed rotary liquid film reactor at room temperature, crystallize the obtained slurry at 100°C for 6 hours, and centrifuge to separate the obtained sample until the pH value is close to 7 to obtain hydrotalcite. body filter cake. After sampling and drying, its molecular formula was determined to be MgAl-NO 3 -LDHs, its Mg 2+ / Al 3+ =2:1.

[0038] Take 30g (containing 0.02mol NO 3 - ) The above filter cake is used to remove CO 2 Ultrasonic dispersion with deionized water to prepare 150ml suspension.

[0039] Step B: Weigh 12g (0.04mol) of aminotrimethylene phosphonic acid (abbreviated as ATMP in Engli...

Embodiment 2

[0043] Step A: 45.0g (0.12mol) of solid Al(NO 3 ) 3 9H 2 O and 61.5g (0.24mol) of solid Mg(NO 3 ) 2 ·6H 2 O dissolves in removing CO 2 300ml of mixed salt solution A was prepared in deionized water; another 28.8g (0.72mol) of solid NaOH was dissolved in 2 300ml of alkaline solution B was prepared in deionized water. Rapidly nucleate the alkali solution and the salt solution in a fully back-mixed rotary liquid film reactor at room temperature, crystallize the obtained slurry at 100°C for 6 hours, and centrifuge to separate the obtained sample until the pH value is close to 7 to obtain hydrotalcite. body filter cake. Take a small amount and dry at 70°C for 24 hours to obtain MgAl-NO 3 -LDHs, its Mg 2+ / Al 3+ =2:1.

[0044] Take 30g (containing 0.02mol NO 3 - ) The above filter cake is used to remove CO 2 Ultrasonic dispersion in deionized water to prepare a 150ml suspension.

[0045] Step B: Weigh 9.1g (0.04mol) of bisglyphosate (abbreviated as PMIDA in English) a...

Embodiment 3

[0049] Step A: 45.0g (0.12mol) of solid Al(NO 3 ) 3 9H2 O and 71.4g (0.24mol) solid Zn(NO 3 ) 3 ·6H 2 O dissolves in removing CO 2 300ml of mixed salt solution A was prepared in deionized water; another 28.8g (0.72mol) of solid NaOH was dissolved in 2 Prepare 300ml of alkaline solution B in deionized water. Rapidly nucleate the alkali solution and the salt solution in a fully back-mixed rotary liquid film reactor at room temperature, crystallize the obtained slurry at 100°C for 6 hours, and centrifuge to separate the obtained sample until the pH value is close to 7 to obtain hydrotalcite. body filter cake. After sampling and drying, its molecular formula was determined to be ZnAl-NO 3 -LDHs, whose Zn 2+ / Al 3+ =2:1.

[0050] Take 30g (containing 0.017mol NO 3 - ) The above filter cake is used to remove CO 2 Ultrasonic dispersion with deionized water to prepare 150ml suspension.

[0051] Step B: Weigh 10.2g (0.034mol) amino trimethylene phosphonic acid (ATMP) and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com