Thixotropic ultraviolet curing adhesive

An adhesive and ultraviolet light technology, used in adhesive additives, modified epoxy resin adhesives, non-polymer adhesive additives, etc., can solve the problem of mechanical properties decline, large structural gap, loss of thixotropic properties, etc. problem, to achieve the effect of good thixotropic performance, high bonding strength and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

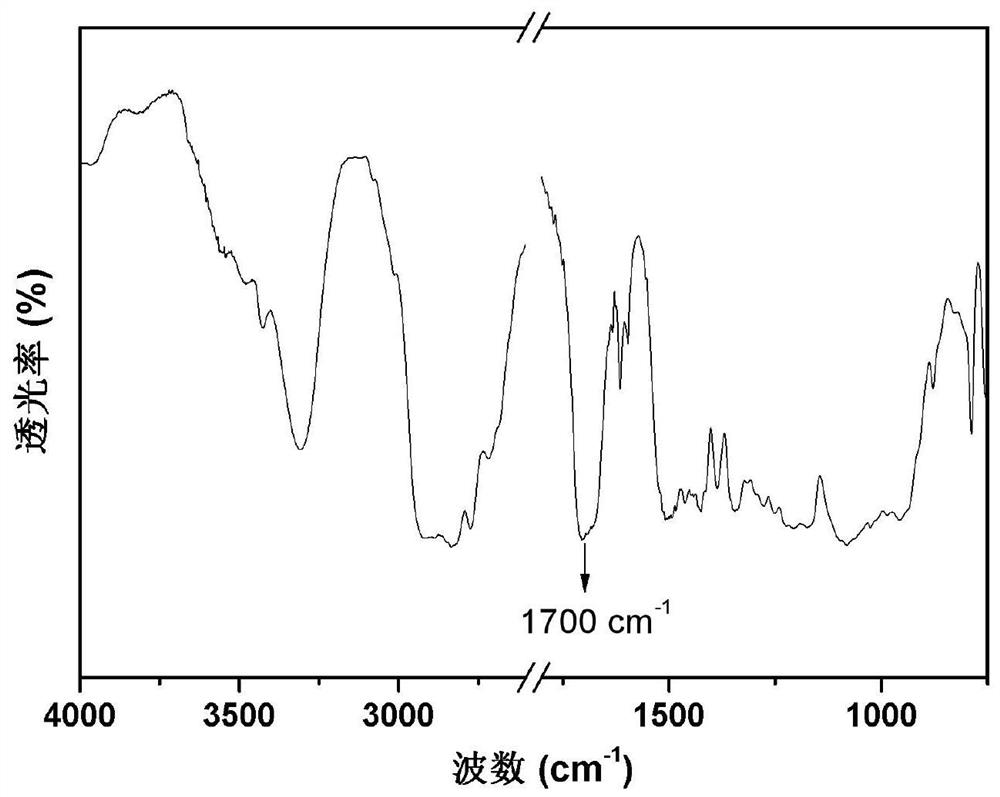

Embodiment 1

[0044]A thixotropic UV-curable adhesive, comprising the following components in parts by weight: carbonate acrylate (a carbonate with a main chain structure of 1,6-hexanediol structure, with an average molecular weight of about 3200 g / mol) 20 parts, 35 parts of divinyl bisphenol A epoxy resin (molecular weight about 440 g / mol), 42.9 parts of glycidyl methacrylate, aliphatic hyperbranched polyester (molecular weight about 500 g / mol, average terminal hydroxyl The number is 5) 3 parts, 1-hydroxycyclohexyl phenyl ketone 2 parts, antifoaming agent tego931 0.1 part, hydroquinone 0.01 part.

[0045] The viscosity of the product of Example 1 was tested with a Brookfield viscometer at a temperature of 25° C. at two rotational speeds of 1 and 10 rpm, and the thixotropic properties were calculated. Under the two conditions of rotational speed of 1 and 10 rpm, the measured viscosities were 4200 and 2900 mPa.s respectively, and the calculated thixotropic index was 1.45.

[0046] Cut a pol...

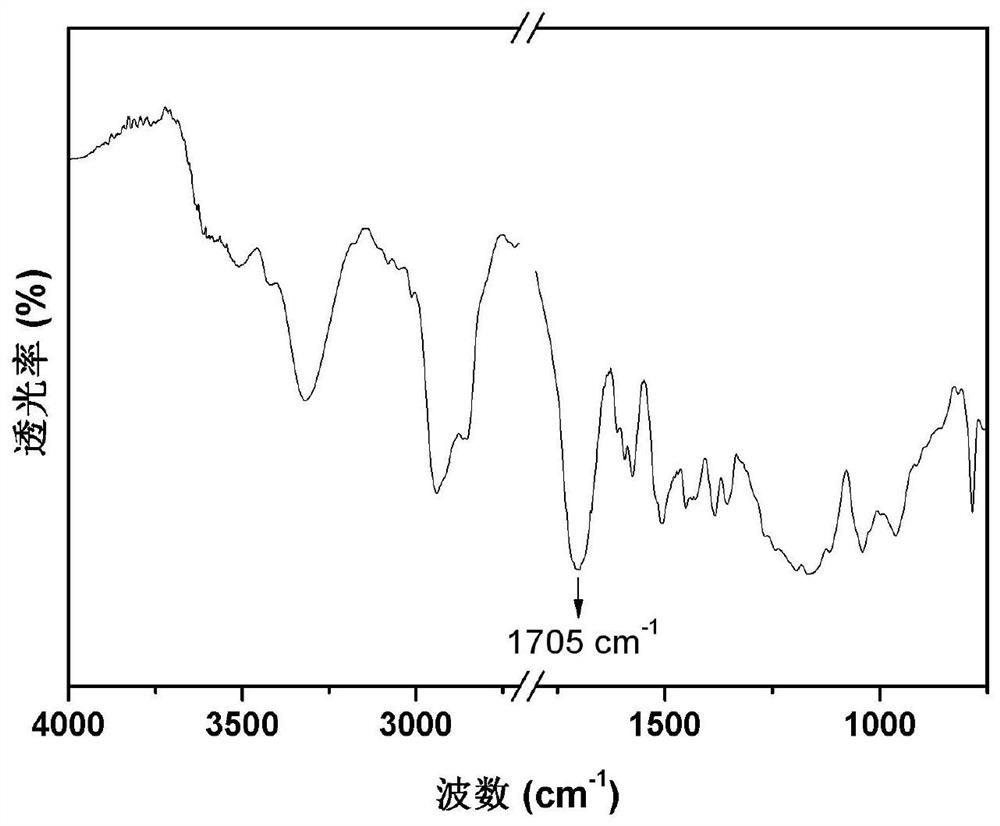

Embodiment 2

[0051] A thixotropic UV-curable adhesive, comprising the following components in parts by weight: carbonate methacrylate (carbonate whose main chain structure is a mixture of 1,6-hexanediol and 1,5-pentanediol, Average molecular weight is about 2000 g / mol) 40 parts, divinyl bisphenol F epoxy resin (molecular weight is about 400 g / mol) 10 parts, aliphatic hyperbranched polyester (molecular weight is about 1200 g / mol, average number of terminal hydroxyl groups 12) 5 parts, tetrahydrofuran acrylate 70 parts, phenylbis(2,4,6-trimethylbenzoyl) phosphine oxide 5 parts, defoamer BYK 055 0.4 parts, p-hydroxyanisole 0.02 share.

[0052] The viscosity of the product of Example 2 at 25° C. and two rotational speeds of 1 and 10 rpm was measured with a Brookfield viscometer, and the thixotropic properties were calculated. Under two conditions of rotating speeds of 1 and 10 rpm, the measured viscosities were 7900 and 4300 mPa.s respectively, and the calculated thixotropic index was 1.84. ...

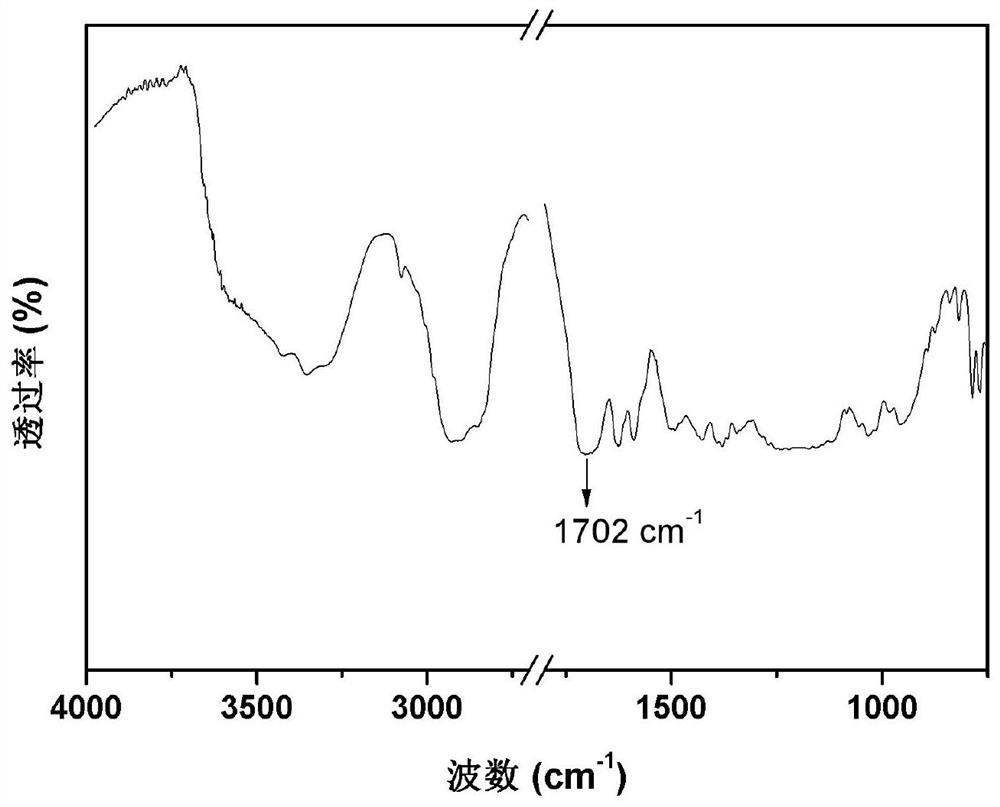

Embodiment 3

[0057] A thixotropic UV-curable adhesive, comprising the following components in parts by weight: carbonate acrylate (a carbonate with a main chain structure of a mixed structure of 1,6-hexanediol and 1,4-butanediol, Average molecular weight about 2400 g / mol) 30 parts, divinyl bisphenol A type epoxy resin (molecular weight about 440 g / mol) 25 parts, cyclotrimethylolpropane formal acrylate 50 parts, aliphatic overrun 4 parts of chemical polyester (molecular weight about 800 g / mol, average number of terminal hydroxyl groups is 7), 3.5 parts of 2-benzyl-2-dimethylamino-1-(4-morpholinephenyl) butanone, 0.2 part of defoamer EFKA2720, 0.02 part of p-tert-butylcatechol, to obtain the product of Example 3.

[0058] The viscosity of the product of Example 3 at 25° C. and two rotational speeds of 1 and 10 rpm were respectively measured with a Brookfield viscometer, and the thixotropic properties were calculated. Under two conditions of rotating speeds of 1 and 10 rpm, the measured visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com