Polyimide film and preparation method and applications thereof

A technology of reactive and aromatic diamines, which is applied in the field of space environment stable polymer materials, can solve the problems of poor optical transparency of films and difficulty in meeting the requirements of space vehicle optical components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

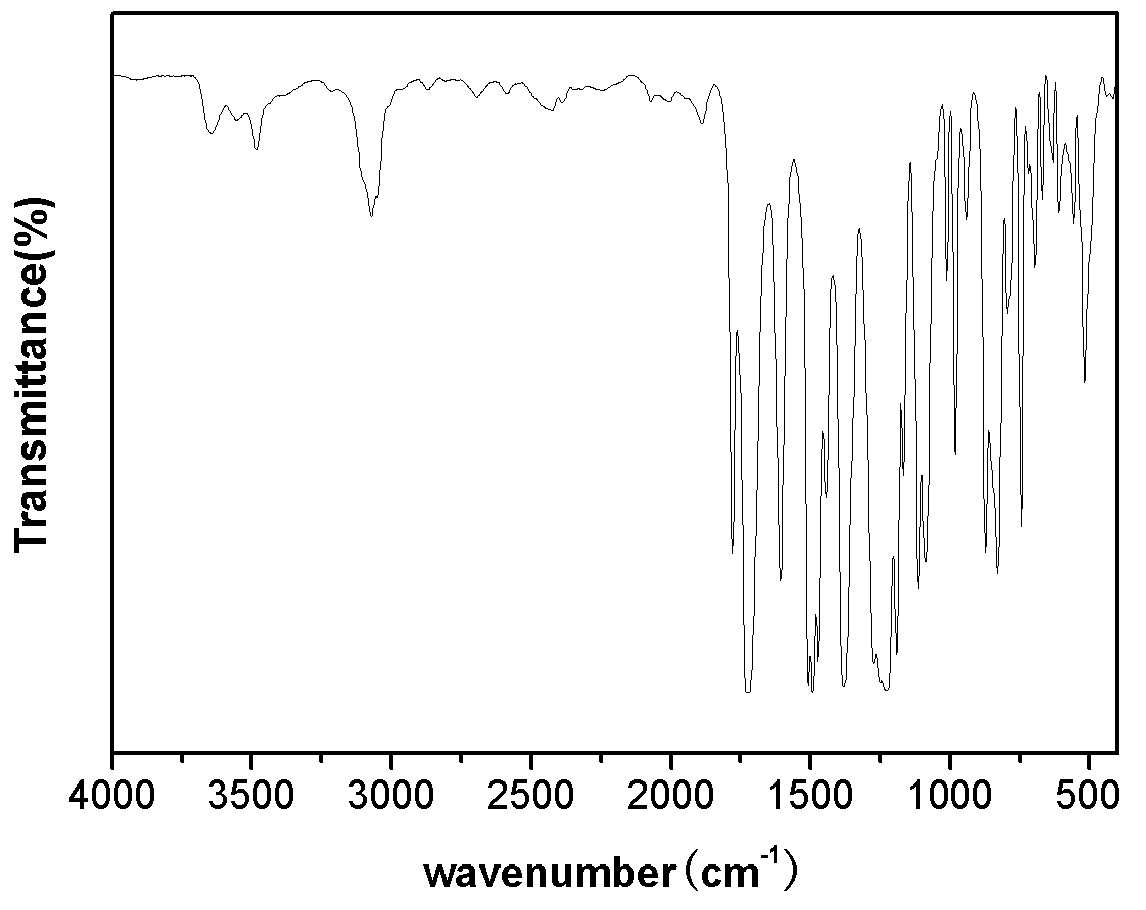

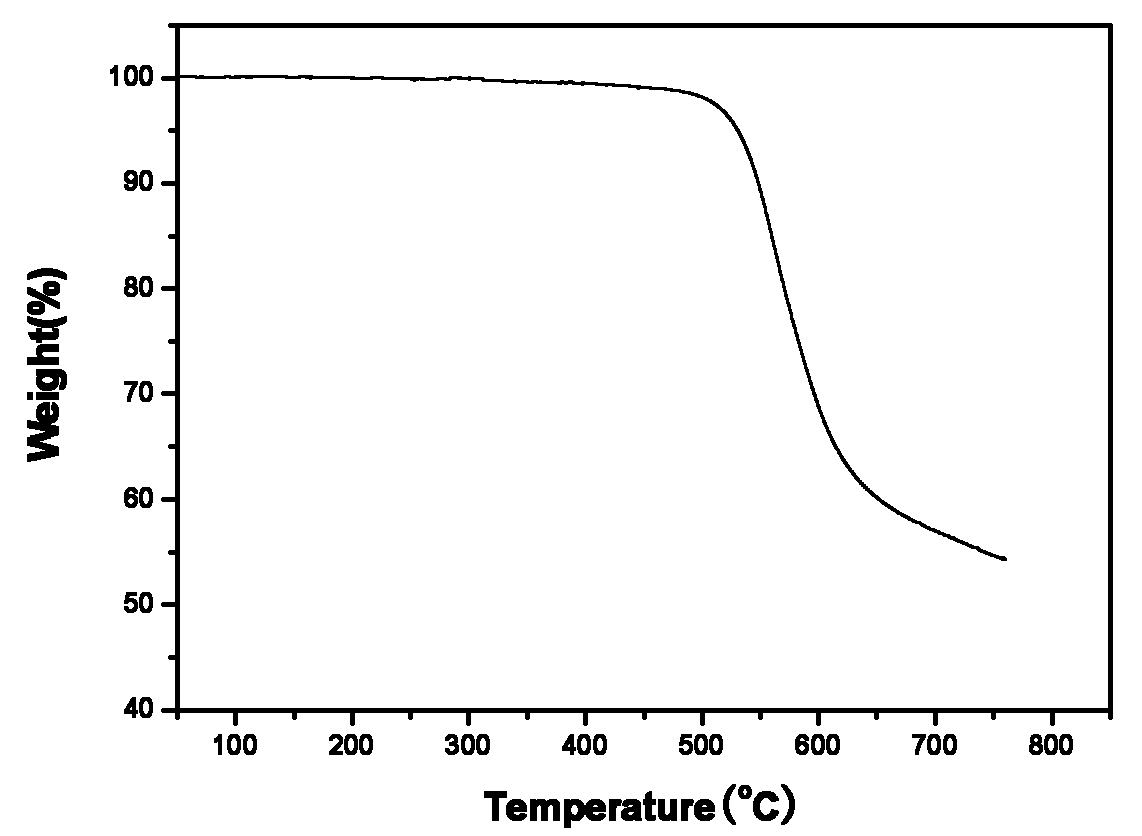

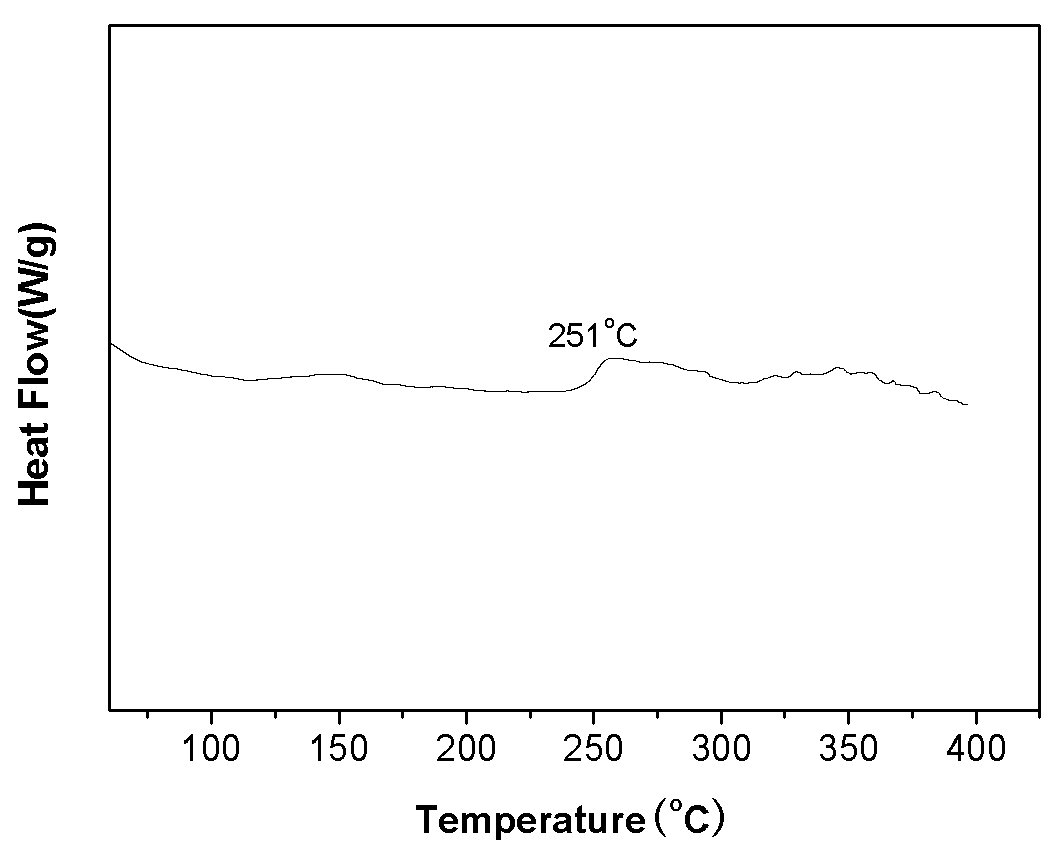

[0048] Embodiment 1, prepare polyimide by aODPA and 1,4-bis(4-aminophenoxy)benzene (144APB)

[0049] 1) Add 0.01mol (2.9233g) of 144APB and 15ml of N-methylpyrrolidone (NMP) into a 100ml three-necked flask equipped with a nitrogen inlet. After stirring at room temperature to dissolve completely, add 0.01mol (3.1021g) aODPA, and continue stirring at 20°C for 24 hours to obtain a homogeneous liquid system;

[0050] 2) Add 0.03mol (2.86ml) acetic anhydride and 0.03mol (2.45ml) pyridine to the homogeneous liquid system obtained in step 1), continue to stir for 24h, and the polyimide compound shown in the formula II is obtained after the reaction is completed. It is a yellow viscous solution, and the mass percentage of the target product is 18%;

[0051] 3) Pour the yellow viscous solution obtained in step 2) into 300ml of ethanol to obtain a white filamentous solid. Collect the solid, wash it with ethanol three times, and dry it in an oven at 80° C. for 12 hours under normal pre...

Embodiment 2

[0069] Embodiment 2, prepare polyimide by aODPA and 1,3-bis(3-aminophenoxy)benzene (133APB)

[0070] 1) Add 0.01mol (2.9233g) 133APB and 15ml m-cresol to a 100ml three-necked flask equipped with a nitrogen inlet. After stirring at room temperature to dissolve completely, add 0.01mol (3.1021g) aODPA, and continue stirring at 25°C for 25 hours to obtain a homogeneous liquid system;

[0071] 2) Add 0.03mol (2.86ml) acetic anhydride and 0.03mol (2.45ml) pyridine to the homogeneous liquid system obtained in step 1), continue to stir for 25h, and the polyimide compound shown in the formula III is obtained after the reaction is completed. It is a yellow viscous solution, and the mass percentage of the target product is 25%;

[0072] 3) Pour the yellow viscous solution obtained in step 2) into 300ml of ethanol to obtain a white filamentous solid, collect the solid, wash it with ethanol three times, and dry it in an oven at 80°C for 12 hours at normal pressure to obtain a filamentous ...

Embodiment 3

[0090] Embodiment 3, prepare polyimide by aODPA and two [4-(4-aminophenoxy) phenyl] hexafluoropropane (BDAF)

[0091] 1) Add 0.01mol (5.1845g) BDAF and 15ml N-methylpyrrolidone (NMP) into a 100ml three-necked flask equipped with a nitrogen inlet. After stirring at room temperature to dissolve completely, add 0.01mol (3.1021g) aODPA, and continue stirring at 25°C for 20 hours to obtain a homogeneous liquid system;

[0092] 2) Add 0.03mol (2.86ml) acetic anhydride and 0.03mol (2.45ml) pyridine to the homogeneous liquid system obtained in step 1), continue to stir for 20h, and the polyimide compound shown in formula IV is obtained after the reaction is completed. It is a yellow viscous solution, and the mass percentage of the target product shown in the formula IV is 18%;

[0093]3) Pour the yellow viscous solution obtained in step 2) into 300ml of ethanol to obtain a white filamentous solid. Collect the solid, wash it with ethanol three times, and dry it in an oven at 80° C. f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com