Patents

Literature

43results about How to "Consistent activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stabilized Exendin-4 compounds

InactiveUS7544657B2Easy to storeImprove consistencyNervous disorderPeptide/protein ingredientsIsomerizationAgonist

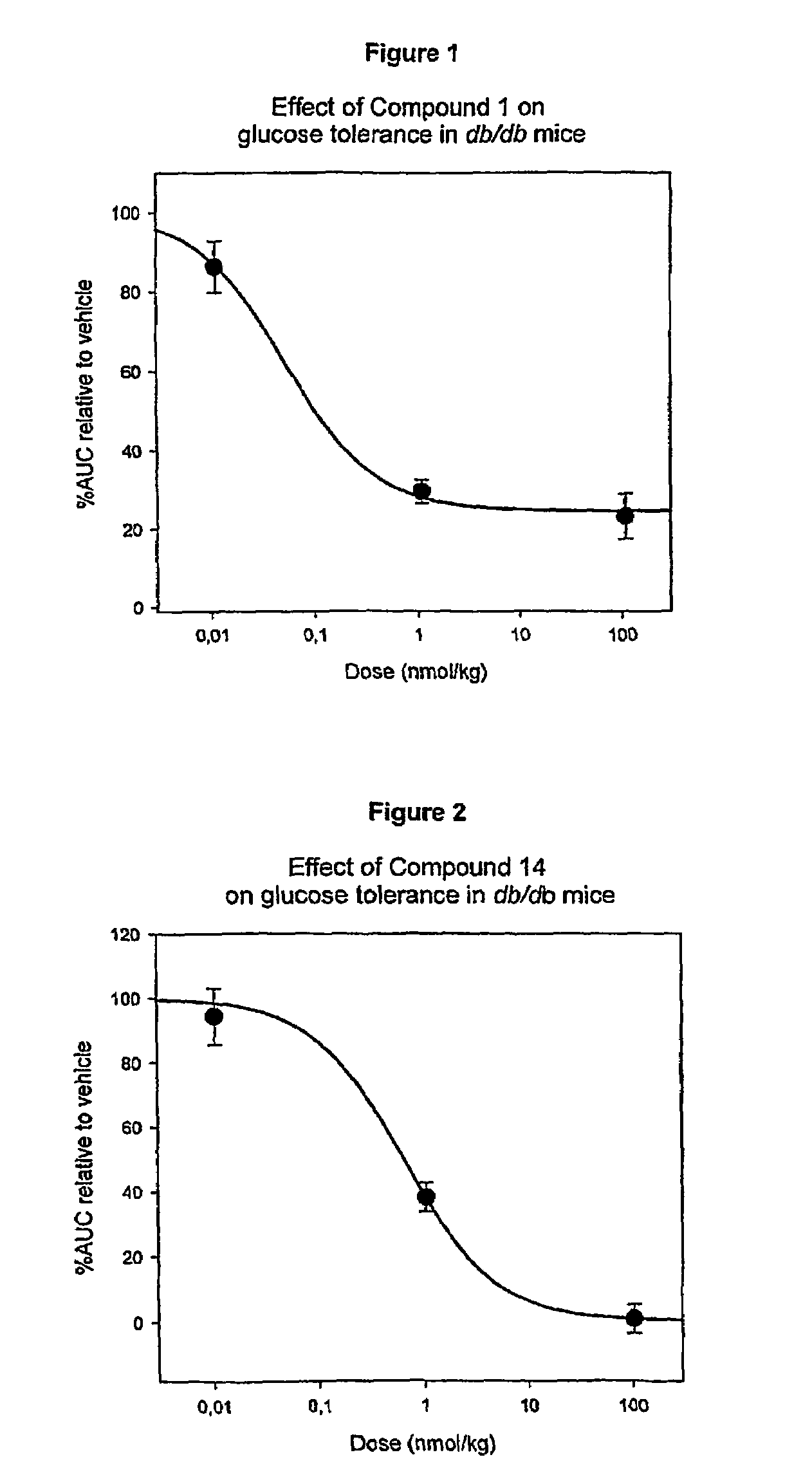

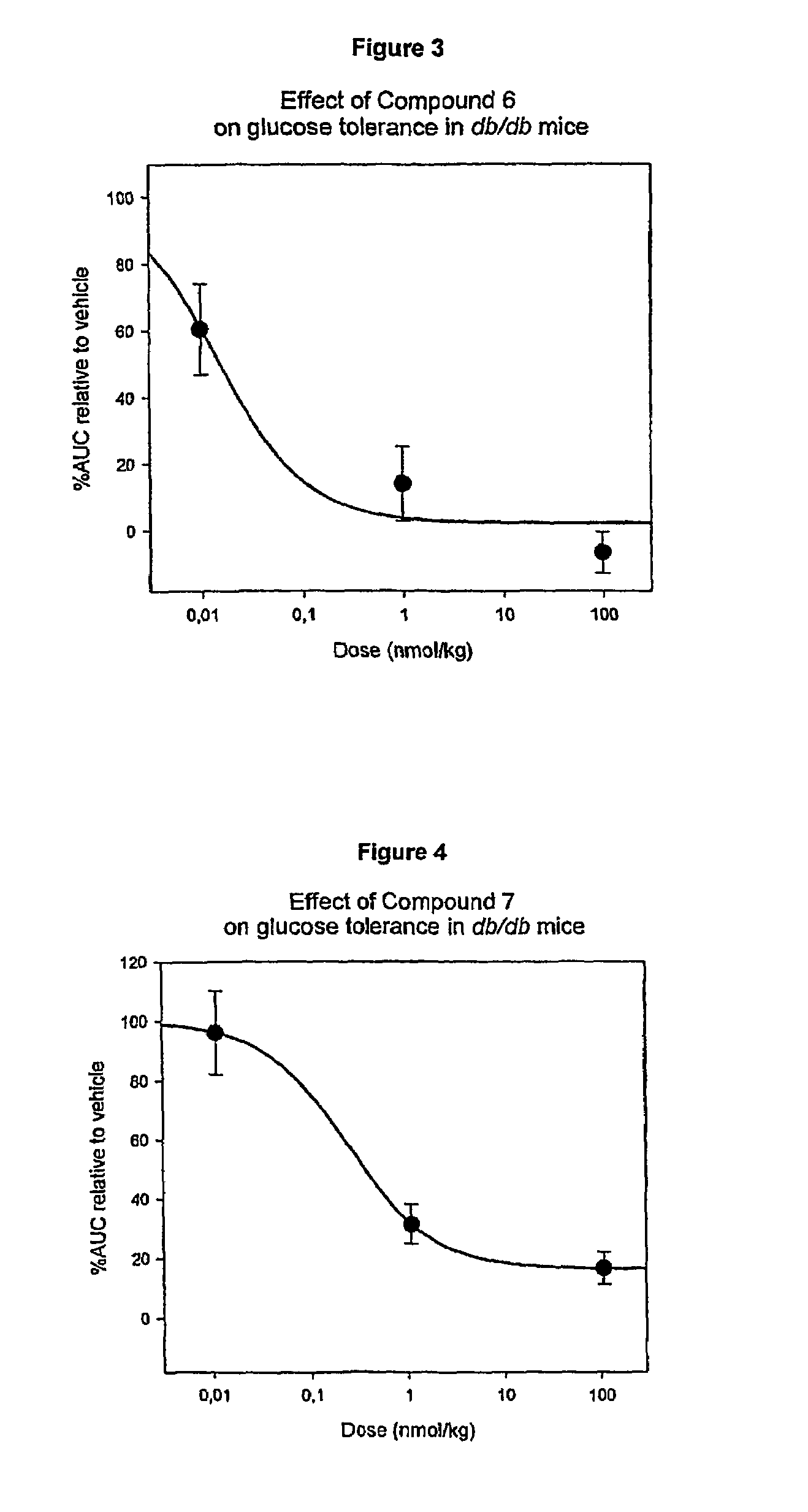

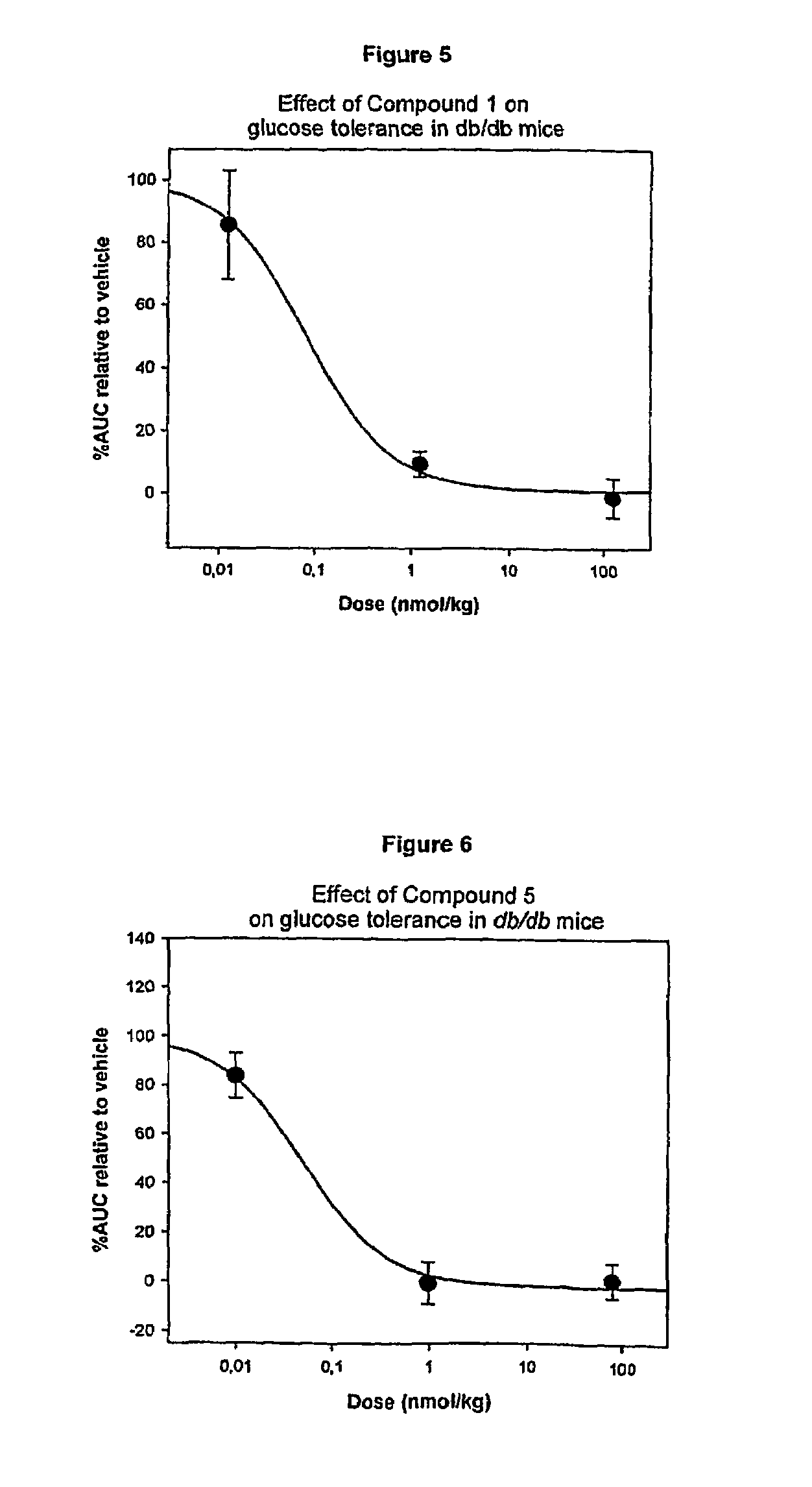

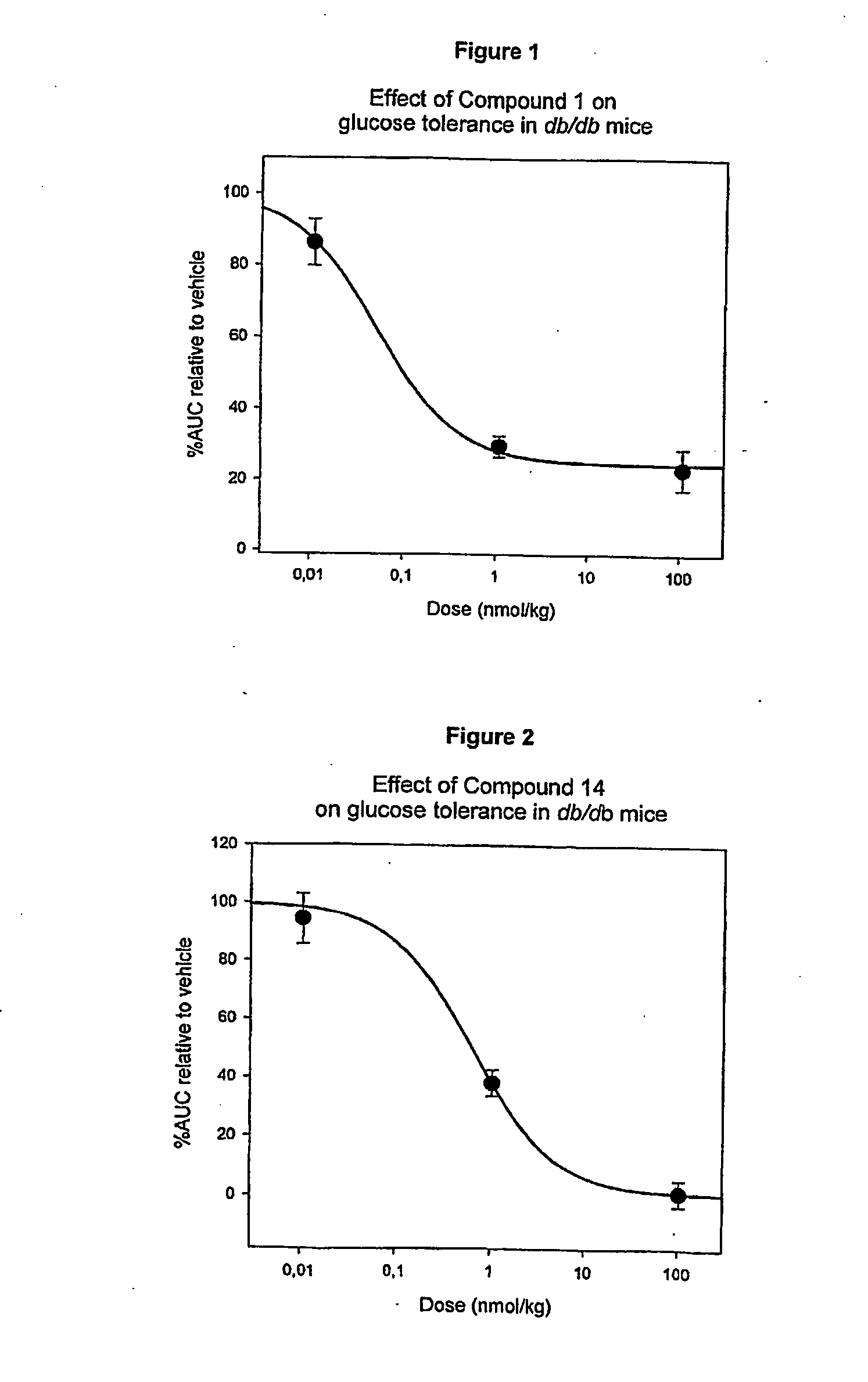

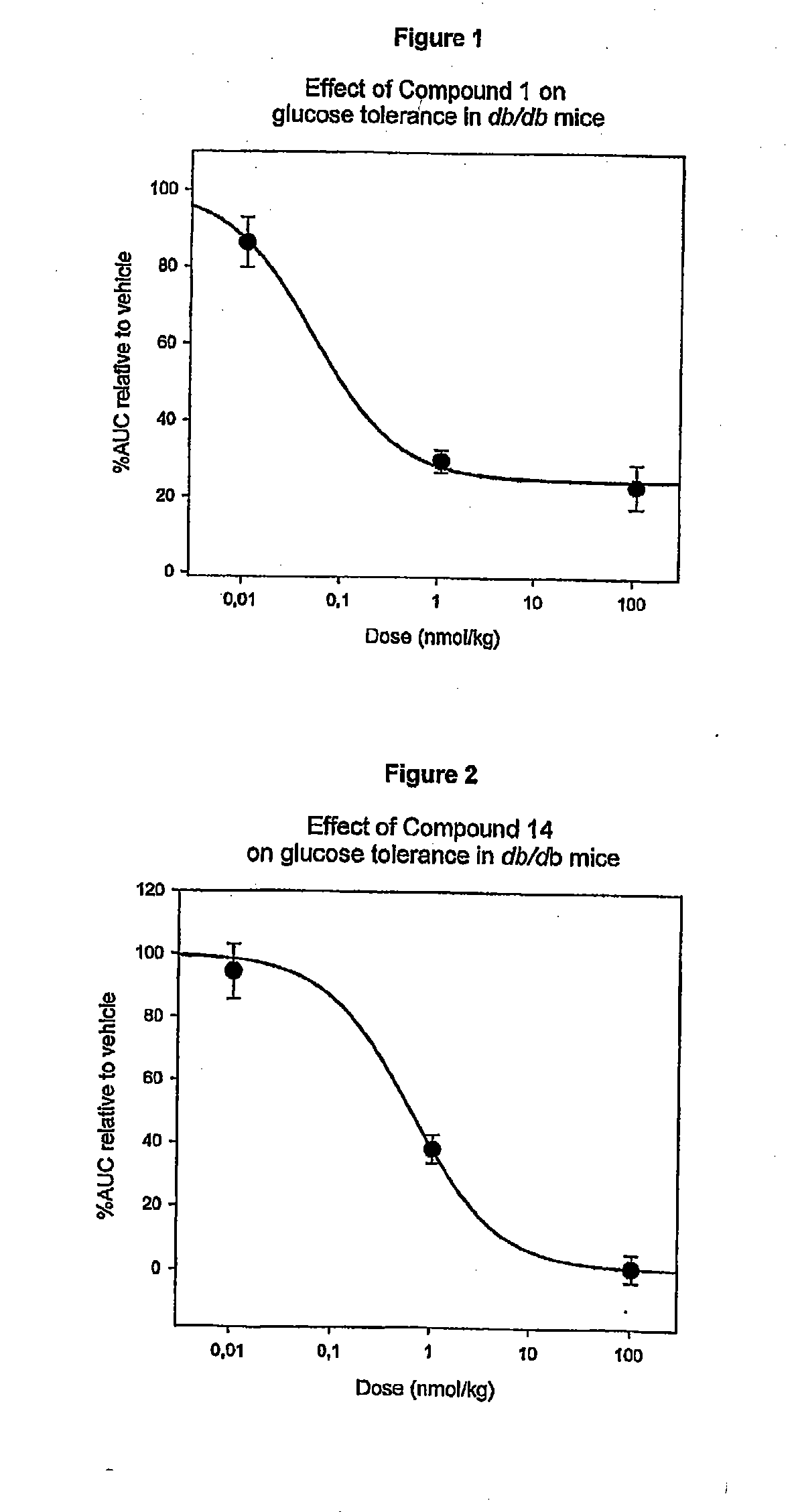

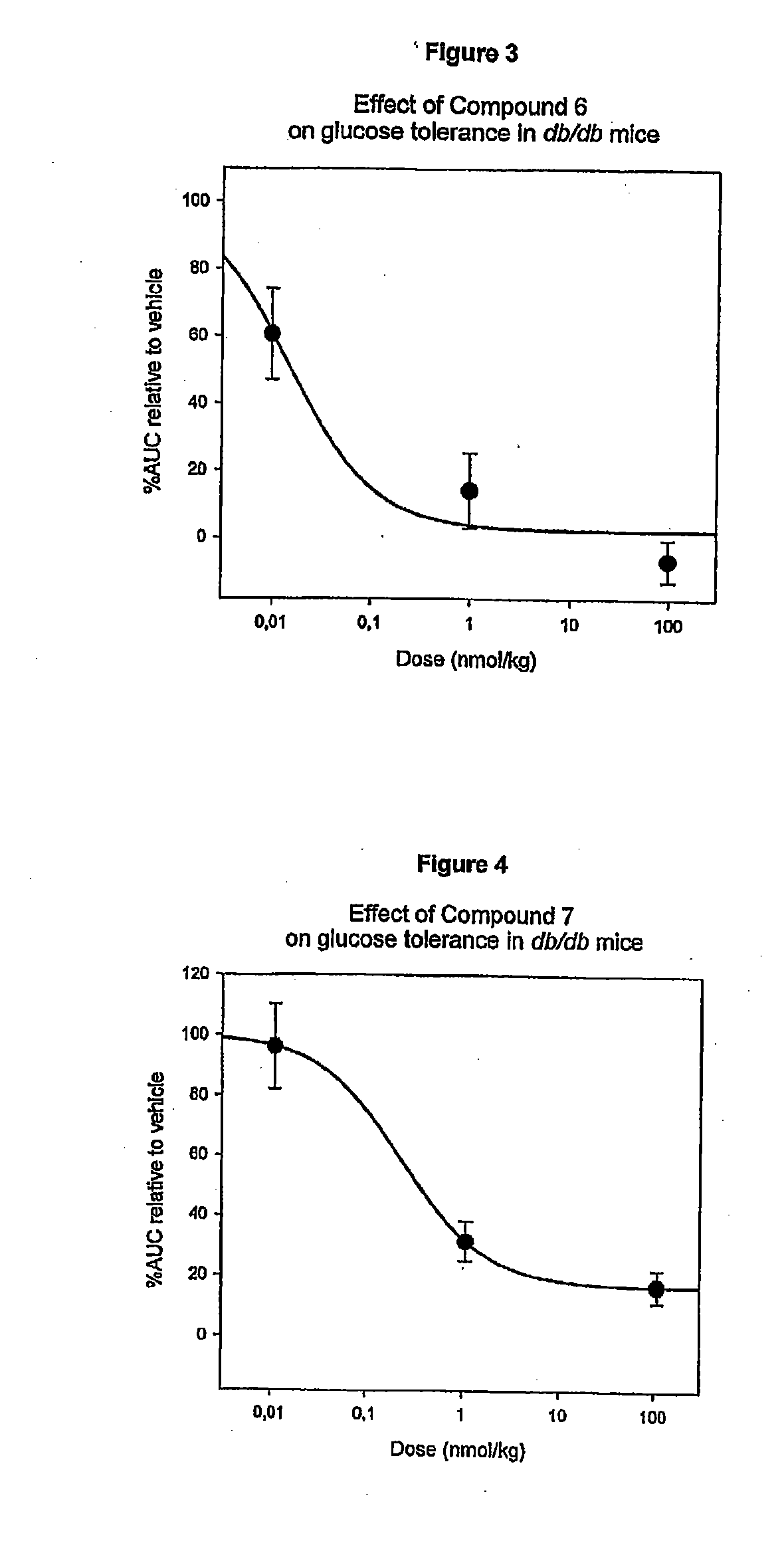

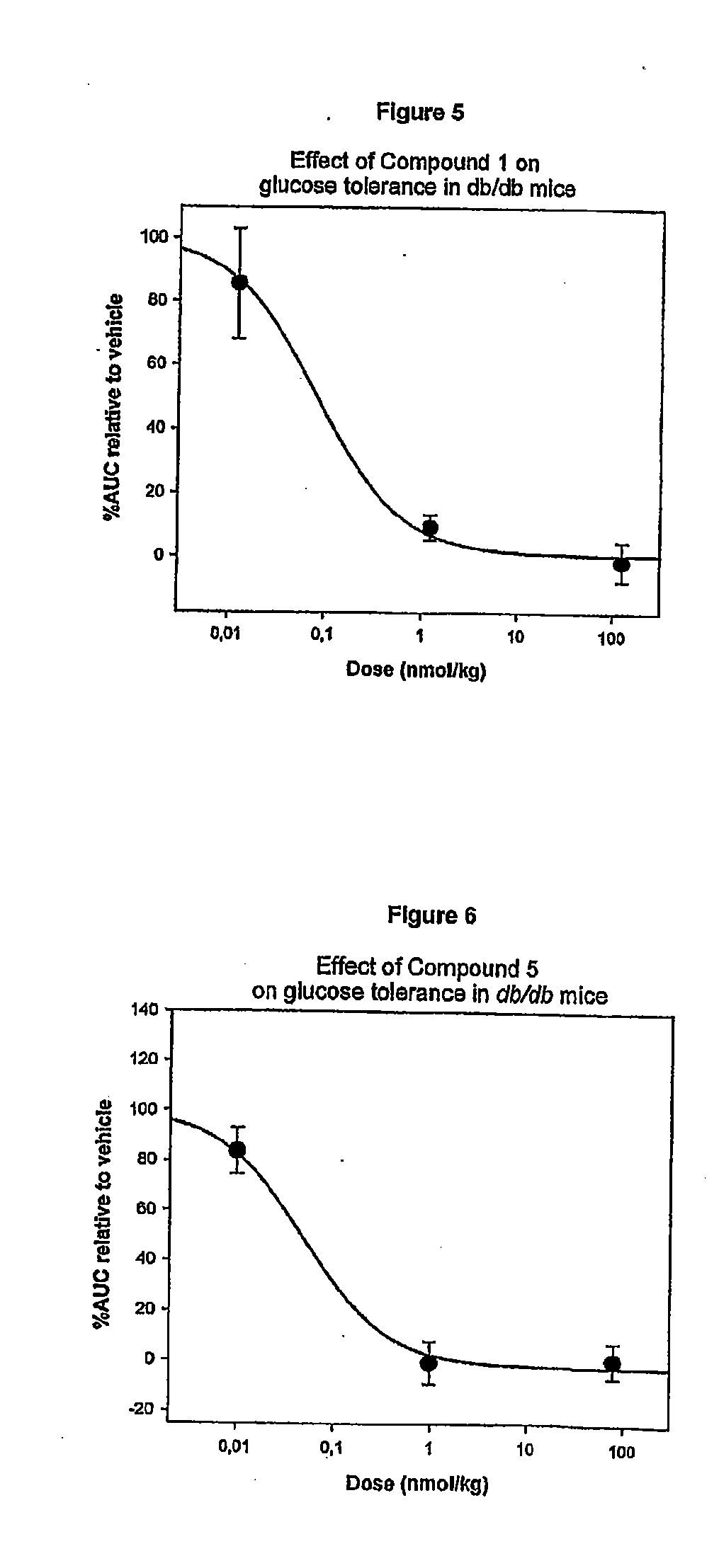

The present invention disclosed compositions comprising a stabilized Exendin-4 (1-39) and related compounds. The invention describes stabilized Exendin-4 agonists that include at least one modified amino acid residue particularly at positions Gln 13, Met14, Trp25, or Asn28 of the Exendin-4 (1-39) molecule. Disclosed are preferred modifications of deaminated, hydrolyzed, oxidized, or isomerized reaction products of the specified amino acid residues corresponding to the same positions in the Exendin-4 molecule. The invention also relates to methods of making and using the stabilized Exendin compounds, such as for the treatment of diabetes.

Owner:ZEALAND PHARM AS

Stabilized exendin-4 compounds

InactiveUS20060194719A1Easy to storeImprove consistencyNervous disorderPeptide/protein ingredientsDiabetes mellitusIsomerization

The present invention disclosed compositions comprising a stabilized Exendin-4 (1-39) and related compounds. The invention describes stabilized Exendin-4 agonists that include at least one modified amino acid residue particularly at positions Gln 13, Met14, Trp25, or Asn28 of the Exendin-4 (1-39) molecule. Disclosed are preferred modifications of deaminated, hydrolyzed, oxidized, or isomerized reaction products of the specified amino acid residues corresponding to the same positions in the Exendin-4 molecule. The invention also relates to methods of making and using the stabilized Exendin compounds, such as for the treatment of diabetes.

Owner:ZEALAND PHARM AS

Single use lyophilized rnase reagents, and kits and methods for using same

InactiveUS20050164204A1Stable and long lifeEasy to useBioreactor/fermenter combinationsBiological substance pretreatmentsDNAReagent

A single use reagent article which comprises: (a) a holder; and a premeasured single use quantity of at least one lyophilized RNase associated with the holder. This reagent article can be used in a wide variety of biological kits and biological methods, such as molecular biological kits and methods for isolating DNA, where a known quantity of RNase(s) is needed having relatively consistent and stable activity. The reagent article is relatively easy to use and can minimize potential errors to due to user variability.

Owner:GERARD BIOTECH

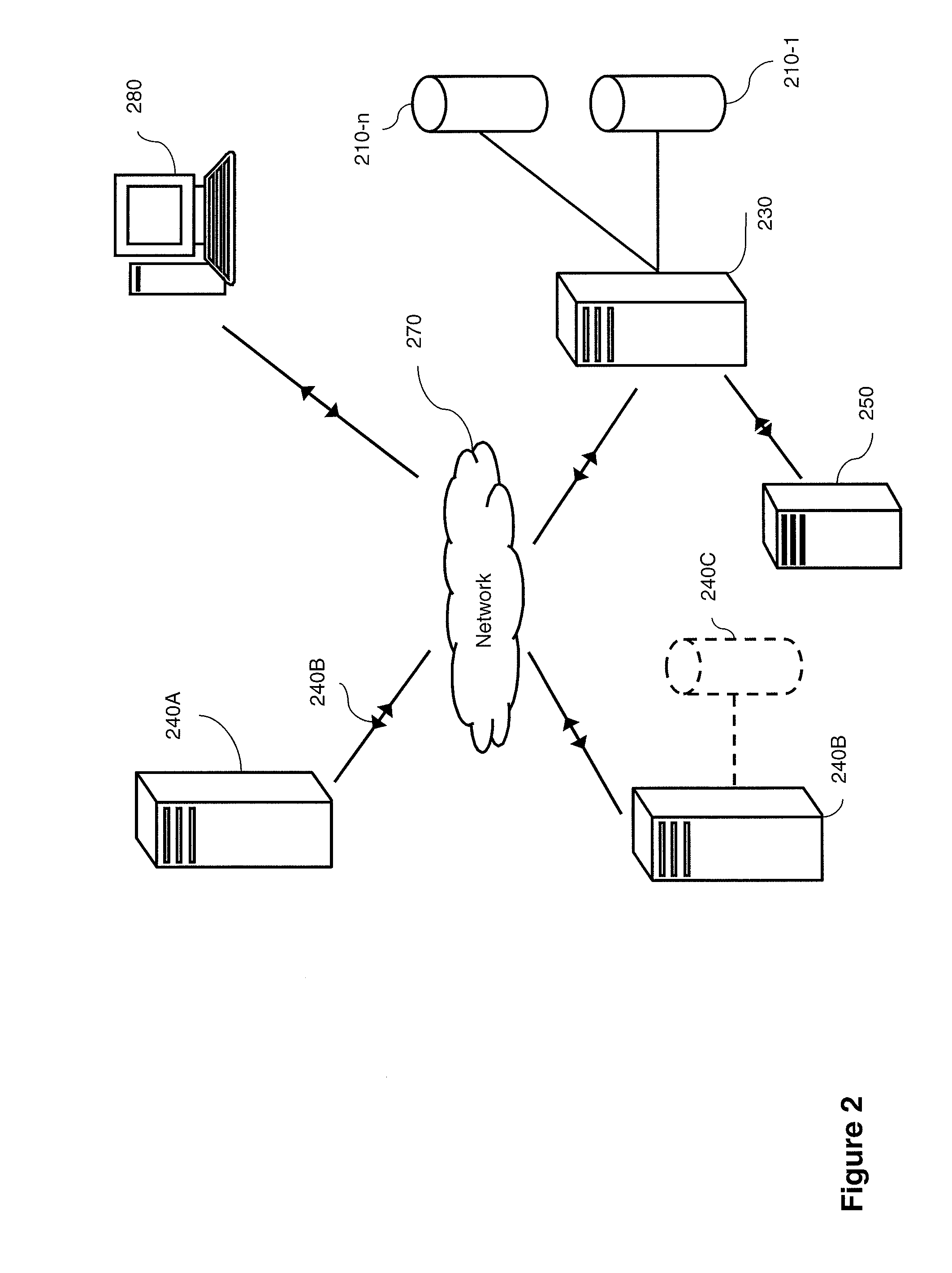

Method and system for implementing definable actions

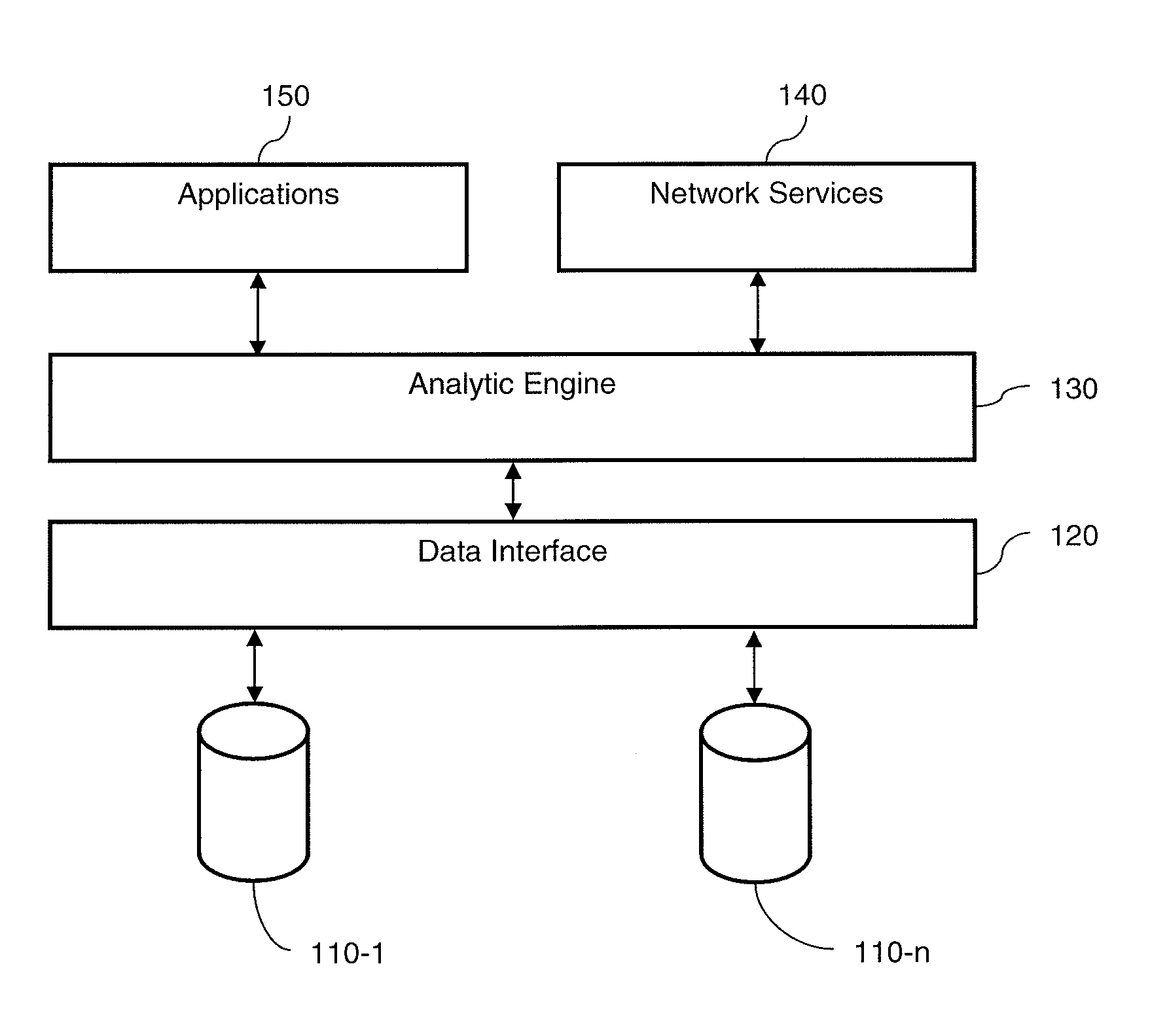

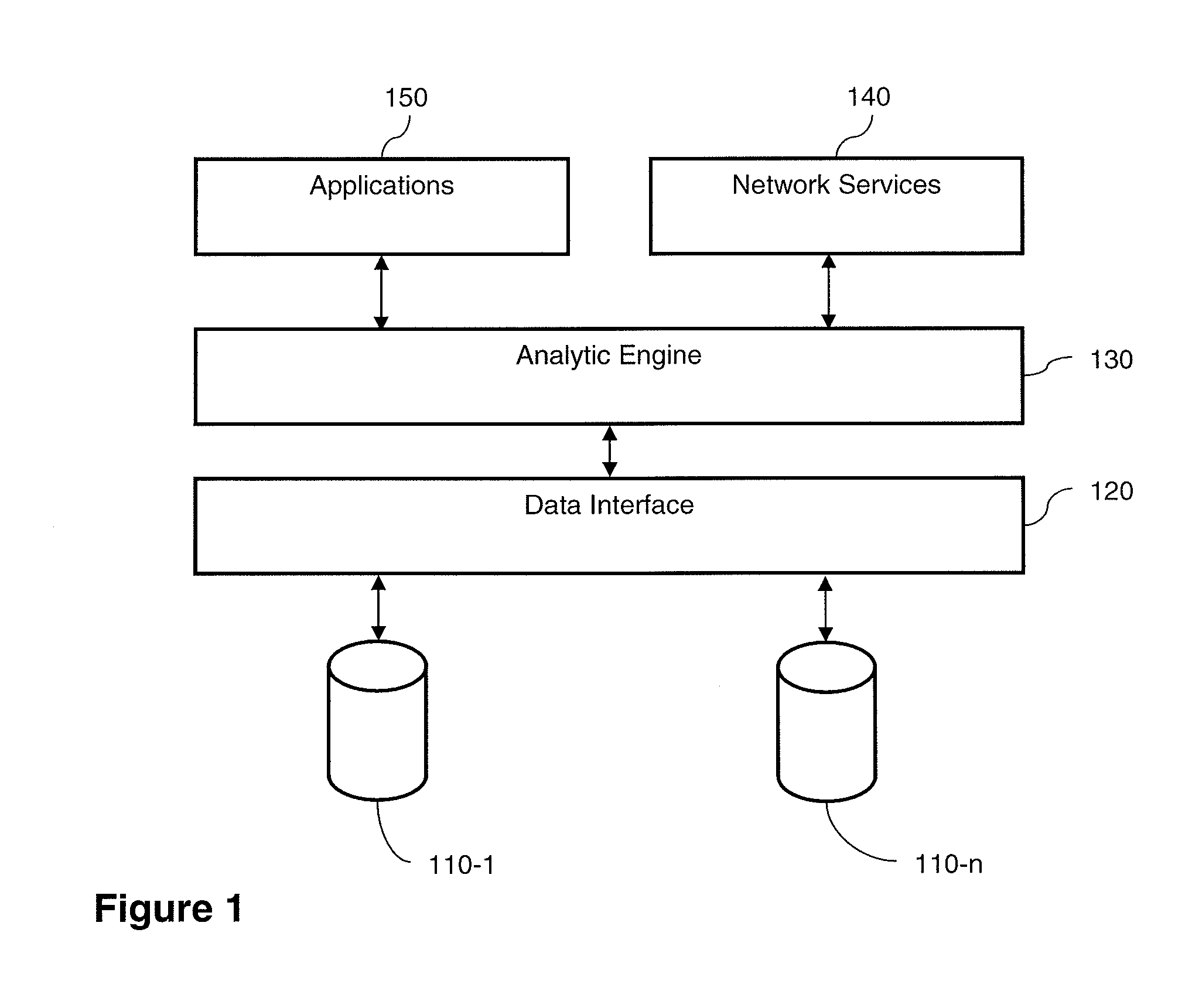

ActiveUS20110173680A1Reduce needConsistent activityDigital data processing detailsUser identity/authority verificationBusiness intelligenceMetadata

A method and system is provided for use in business intelligence and reporting. The method and system are able to implement one or more definable actions when presented with data. The data may be produced by a business intelligence application. The actions may relate to activities performed by a user or an agent. The system comprises an action manager, a repository, a data association manager and an implementation engine. In one embodiment a data mining engine is provided. The system enables the availability of an action in response to the execution of analytic queries to be determined based on a relationship defined by the data association manager. If an action is available, an action definition is used to invoke a target in response to selection of the action by an entity, the invocation of the target including propagating data produced by an analytic engine into the target based on metadata to perform the action.

Owner:ORACLE INT CORP

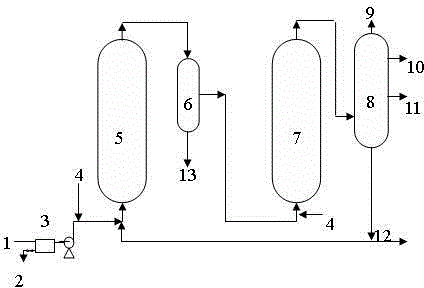

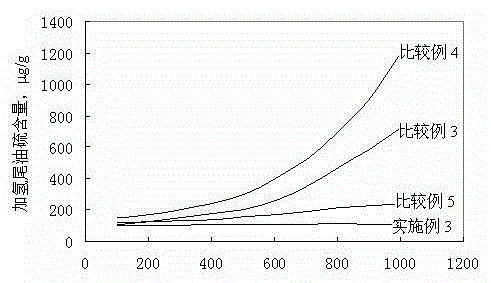

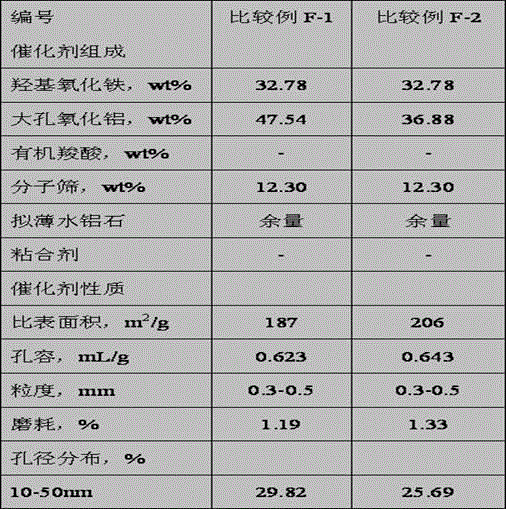

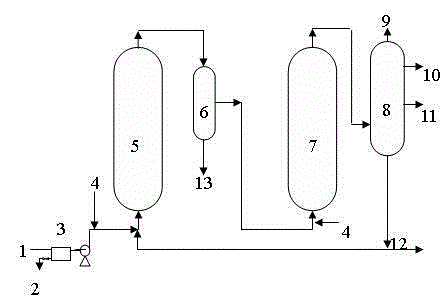

Method for hydrogenation of coal tar via fluidized bed

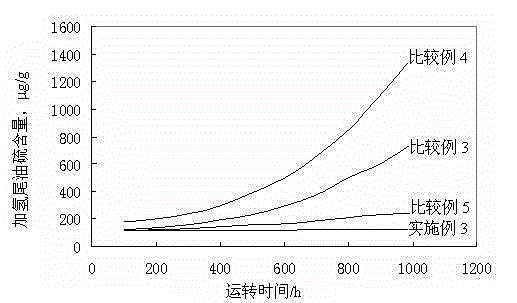

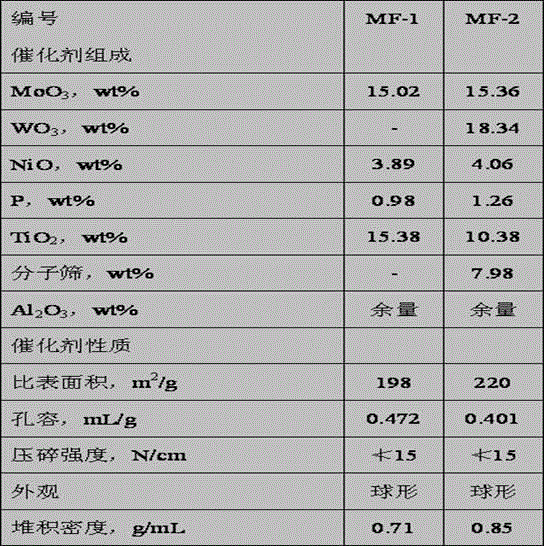

ActiveCN104593060AConsistent activityEasy to removeTreatment with hydrotreatment processesHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention discloses a method for hydrogenation of coal tar via a fluidized bed. The method comprises the following steps: subjecting a coal tar raw material to hydro-upgrading; carrying out separation to remove water; and then carrying out hydrorefining and fractionation so as to obtain a gasoline fraction, a diesel fraction and hydrogenation tail oil. A hydro-upgrading catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina, a molecular sieve and pseudo-boehmite; and a hydrofining catalyst used in the method comprises iron oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina and a binder. The method provided by the invention adopts cheap iron oxyhydroxide as an active metal component, the hydro-upgrading catalyst and the hydro-refining catalyst are graded, so cost is low. According to the invention, moderate cracking of coal tar is carried out before refining of coal tar, so impurities in coal tar are effectively removed, product distribution and product quality are adjusted, and the running period of a device is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing one-dipping two-baking anode carbon block

The invention discloses a method for producing one impregnating two calcining anode carbon blocks, which is on the basis of producing common anode carbon blocks and comprises following steps: selectively using calcined coke, adding a little antioxidant additive, preheating a common anode under the temperature of 280-330DEG C for 18-24 hours, then, hoisting in a high pressure impregnation tank, filling impregnating pitch whose temperature is 160-180DEG C under the vacuum pressure of 0.09-0.094MPa, pressurizing 1.55-1.6MPa, maintaining the pressure for 3-5 hours, hoisting out and cooling to normal temperature, then, calcining for 200-220 hours under the temperature condition that the maximum temperature is 800-900DEG C according to a heating curve, cooling, and then cleaning up to obtain a new one impregnating two calcining anode carbon block. Since the pitch is filled in an air vent of the anode, the mechanicalness and the physical and chemical properties of the anode carbon blocks are newly changed, the bulk density and the compressive strength are increased, the porosity is lowered, the resistivity is lowered, the activity of the binder coke and the activity of aggregate tend to be consistent, the speed of selective oxidation is lowered, the voltage drop of the anode carbon blocks is lowered, and the using period of the anode is prolonged.

Owner:WEN COUNTY DONGFANG CARBON

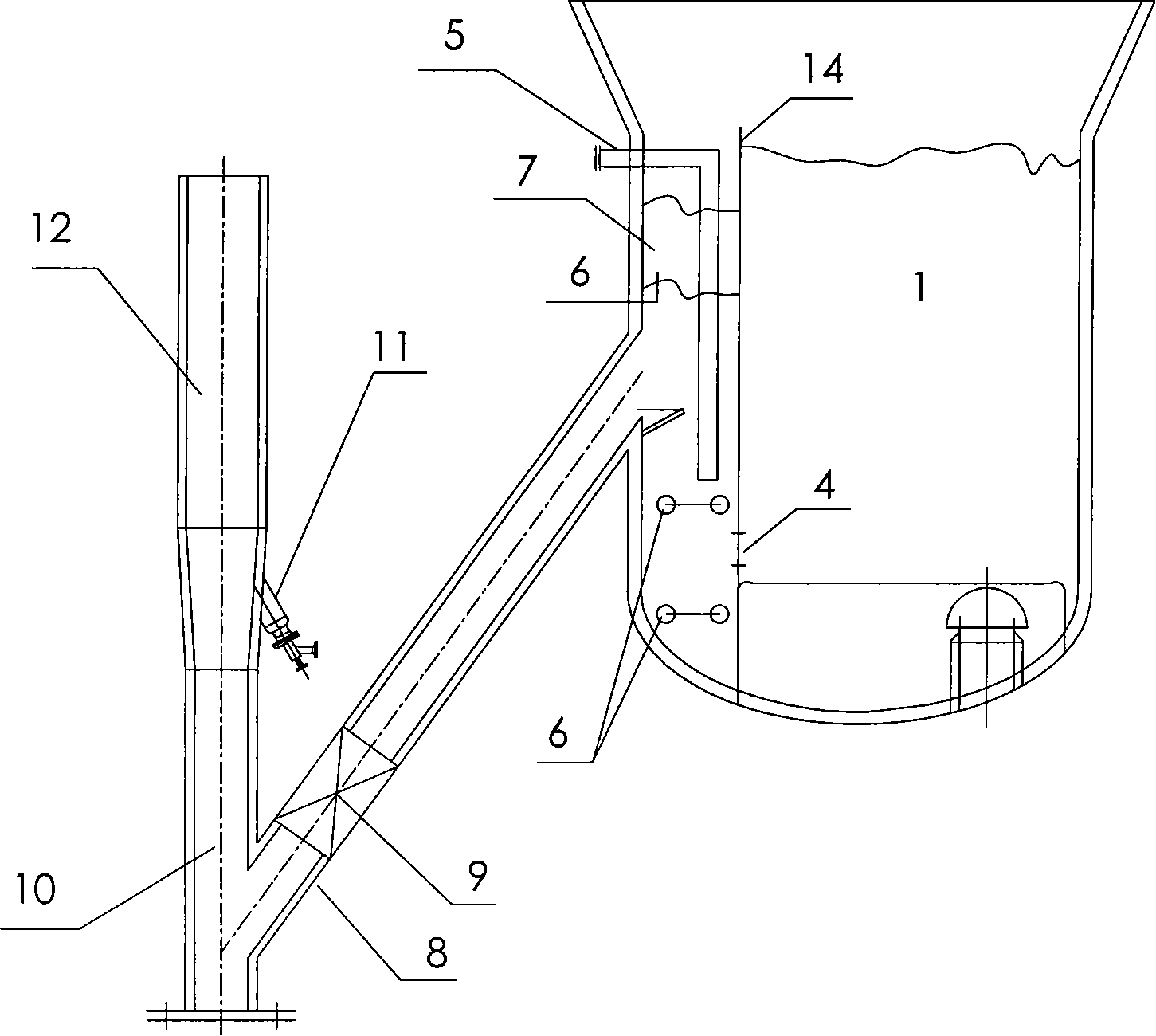

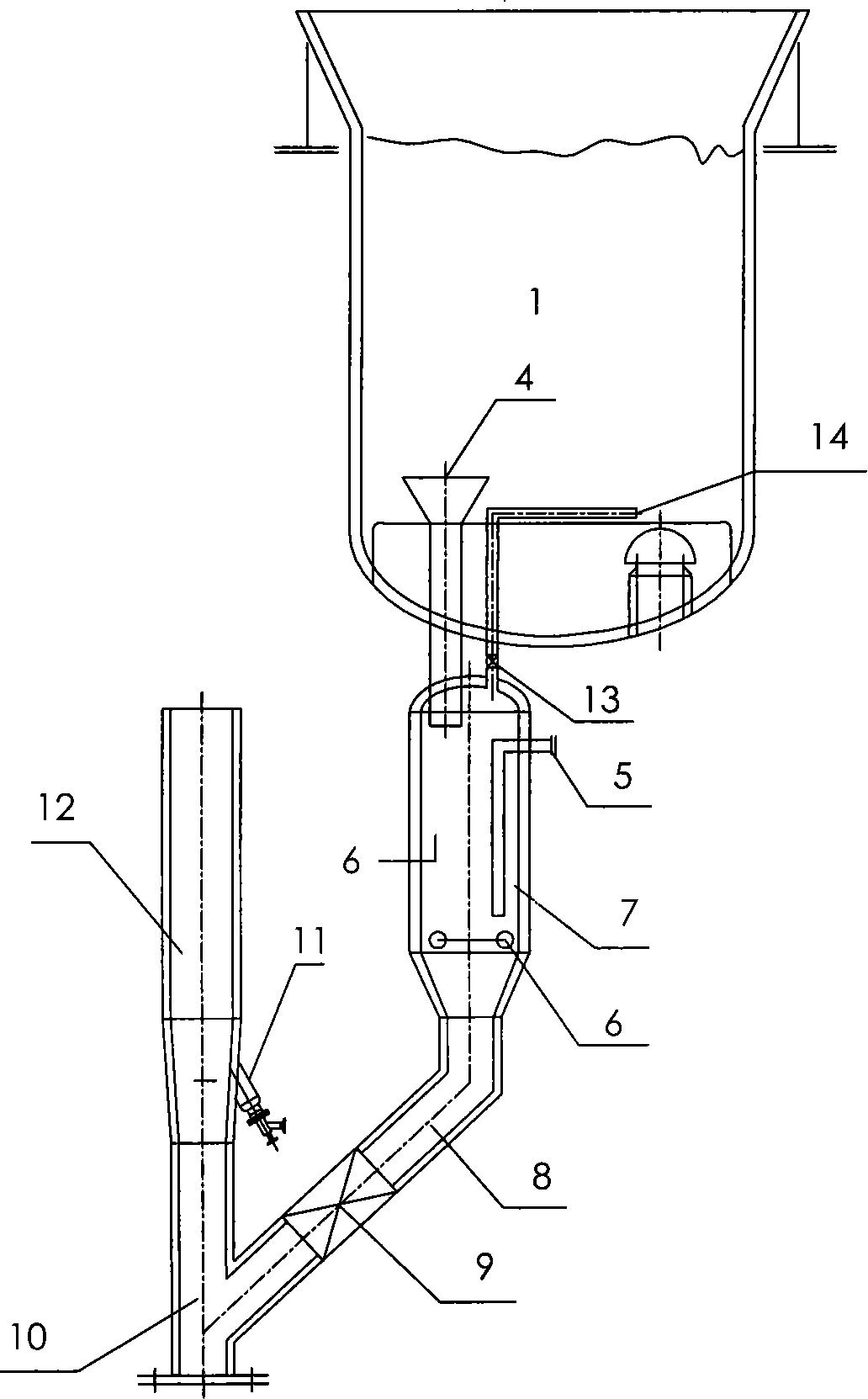

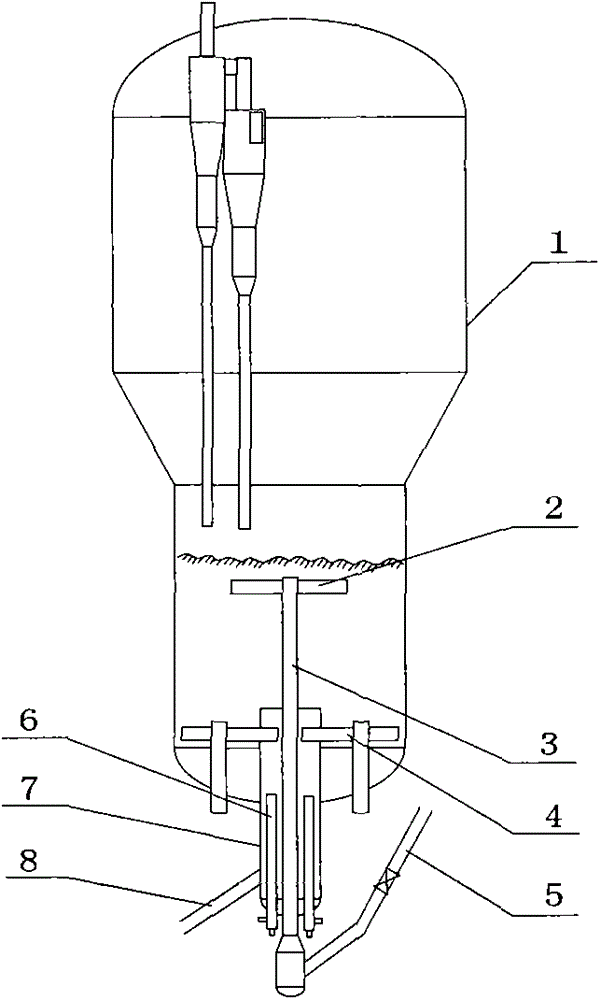

Regenerated catalyst thermoregulation device for catalytic cracking equipment

InactiveCN101191071AHigh reactivityConsistent activityCatalytic crackingBody ThermoregulationCracking reaction

The invention discloses regenerated catalyst temperature adjustment equipment for a catalytic cracker. The equipment can solve the problems that the catalyst-to-oil ratio of the prior catalytic cracker fails to be flexibly improved according to the actual requirement, or the catalyst-to-oil ratio can be adjusted, but has a complex structure. The regenerated catalyst temperature adjustment equipment provided by the invention is characterized in that: a clapboard is arranged in a regenerator dense phase bed and divides the regenerator dense phase bed into two zones, one zone is a regeneration burning zone, the other zone is a catalyst cooler zone, the lower part of the clapboard is provided with a catalyst inlet of the cooler, a heat removing tube is arranged in the catalyst cooler zone, fluidized rings are sectionally arranged along the vertical height of the catalyst cooler zone,a pre-riser arranged on the lower part of a reaction section of a riser reactor is communicated with the catalyst cooler zone through a conveying pipe of regenerated catalyst and a regeneration slide valve. The invention can ensure that the catalyst-to-oil ratio is flexibly improved during the catalytic cracking reaction.

Owner:CHINA PETROCHEMICAL CORP +1

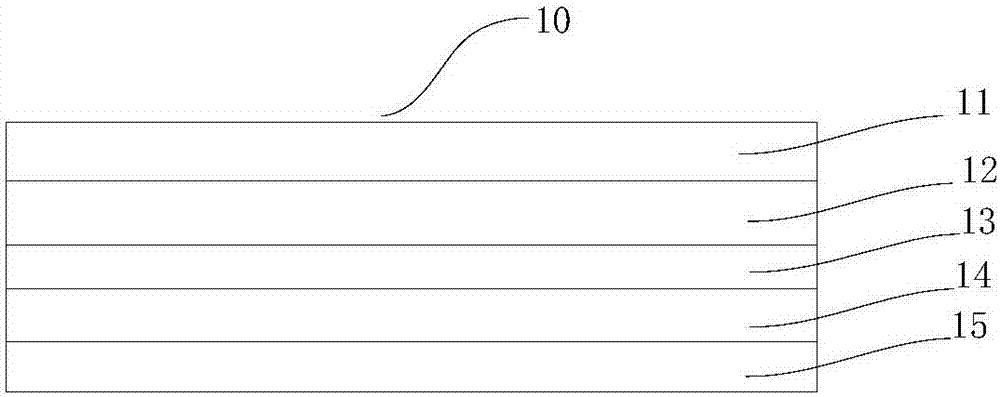

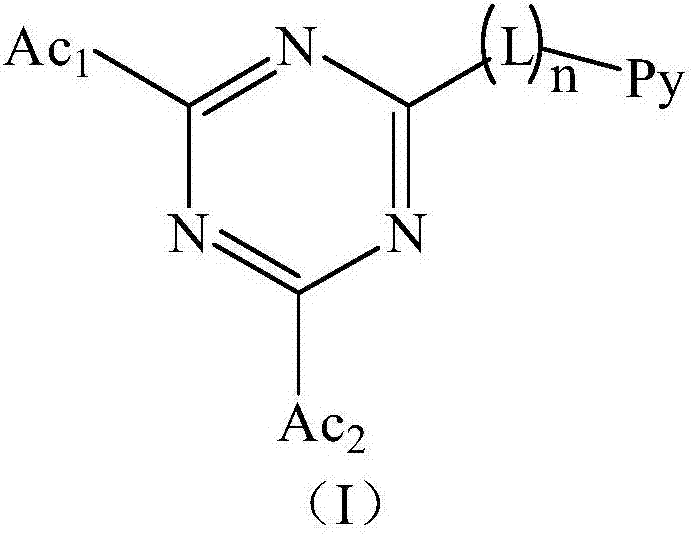

Triazine compound and light-emitting device

InactiveCN106892901AGood planarityRealize the designOrganic chemistrySolid-state devicesTriazeneNitrogen

The invention relates to a triazine compound. The structural formula of the triazine compound is as shown in formula I, wherein L is substituted or non-substituted C6-C24 arylidene; n is 0 or 1; Py is substituted or non-substituted C3-C24 nitrogen-containing heterocyclic groups or nitrogen-containing heterocyclic condensation groups; Ac1 and Ac2 are substituted or non-substituted C12-C48 nitrogen-containing heterocyclic condensation groups; Ac1 and Ac2 can be identical ort different. The invention further relates to a light-emitting device containing the triazine compound. When two nitrogen-containing heterocyclic condensation groups are connected with a triazine group, certain angles are formed between the nitrogen-containing heterocyclic condensation groups and the triazine group due to steric hindrance, and TADF design is achieved.

Owner:AAC MICROTECH CHANGZHOU

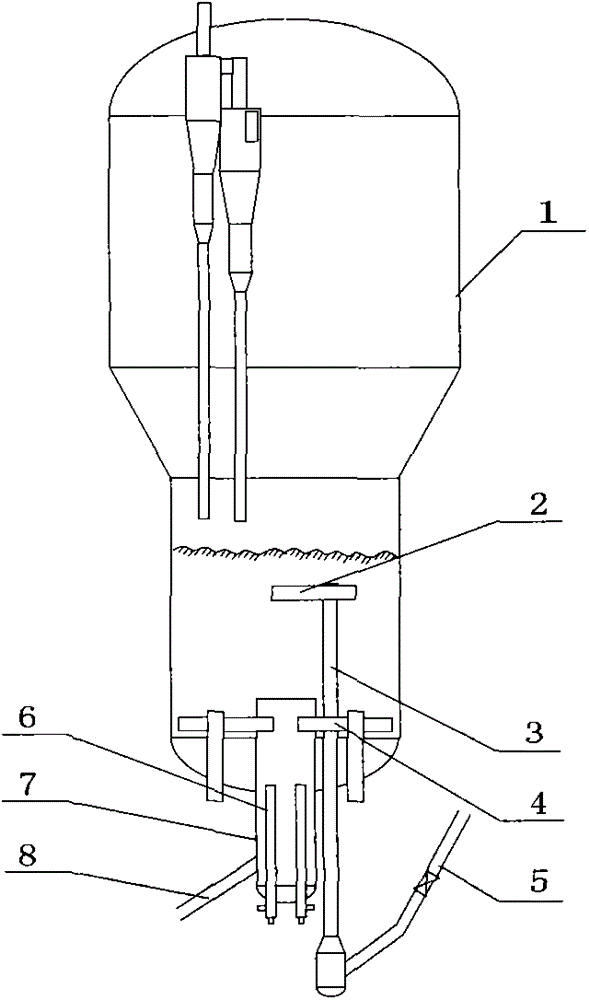

Regenerated catalyst thermoregulation device for catalytic cracking equipment

InactiveCN101191072AHigh reactivityConsistent activityCatalytic crackingCatalyst regeneration/reactivationCracking reactionThermoregulation

The invention discloses regenerated catalyst temperature adjustment equipment for a catalytic cracker. The equipment can solve the problems that the catalyst-to-oil ratio of the prior catalytic cracker fails to be flexibly improved according to the actual requirement, or the catalyst-to-oil ratio can be adjusted, but has a complex structure. The invention is characterized in that: a catalyst cooler is arranged below a regenerator dense phase bed which is communicated with the catalyst cooler through a catalyst extraction hopper arranged at the lower part of the regenerator dense phase bed, a heat removing tube is arranged in the catalyst cooler, fluidized rings are sectionally arranged along the vertical height of the catalyst cooler,the upper part of the catalyst cooler is provided with a fume return device, and the fume return device is provided with a throttling device. The invention can ensure that the catalyst-to-oil ratio is flexibly improved during the catalytic cracking reaction.

Owner:CHINA PETROCHEMICAL CORP +1

Stabilized exendin-4 compounds

InactiveUS20090208565A1Easy to storeImprove consistencyNervous disorderMetabolism disorderIsomerizationAgonist

The present invention discloses compositions comprising a stabilized Exendin-4 (1-39) and related compounds. The invention describes stabilized Exendin-4 agonists that include at least one modified amino acid residue particularly at positions Gln13, Met14, Trp25, or Asn28 of the Exendin-4 (1-39) molecule. Disclosed are preferred modifications of deaminated, hydrolyzed, oxidized, or isomerized reaction products of the specified amino acid residues corresponding to the same positions in the Exendin-4 (1-39) molecule. The invention also relates to methods of making and using the stabilized Exendin compounds, such as for the treatment of diabetes.

Owner:ZEALAND PHARM AS

Derivatives of native lignin from softwood feedstocks

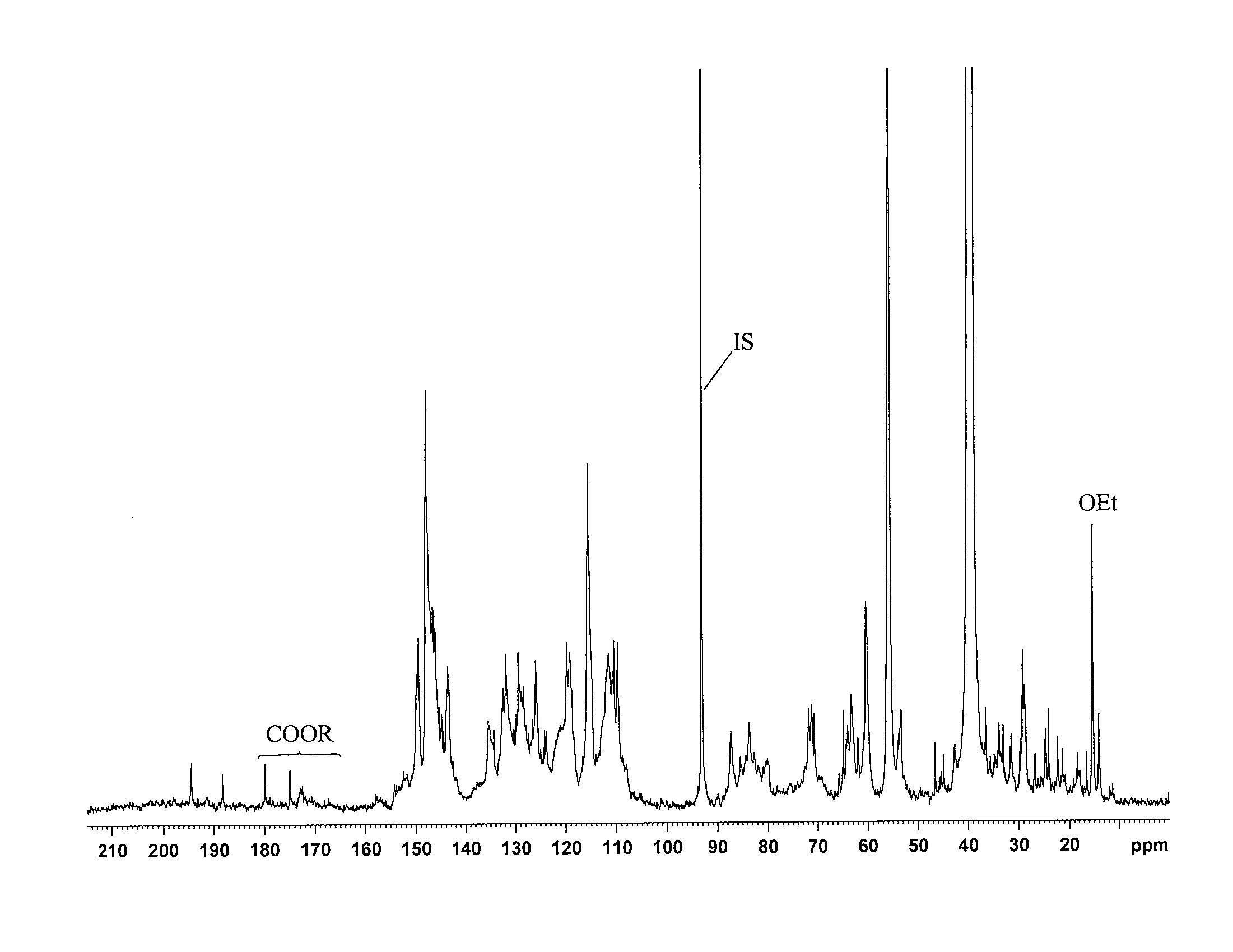

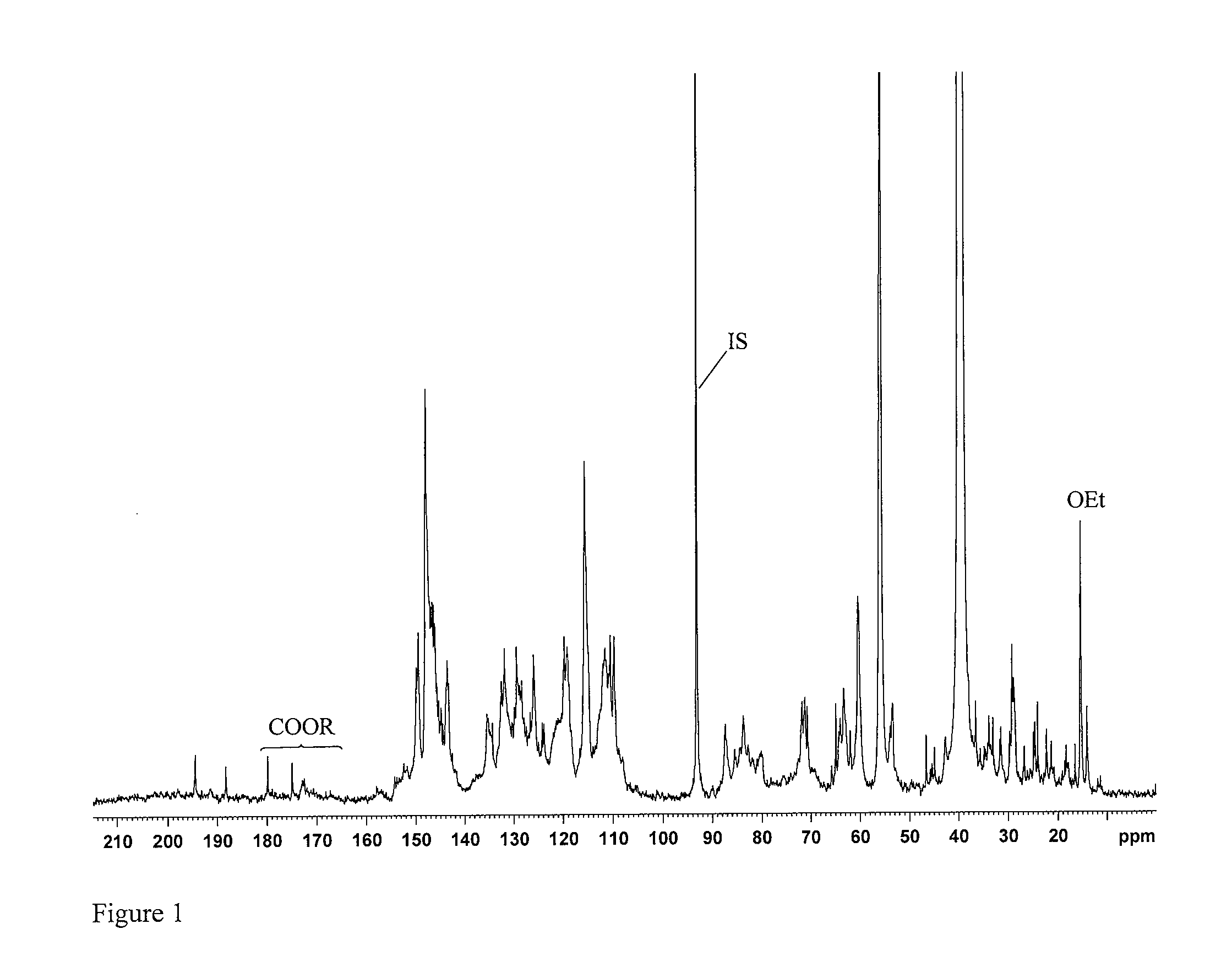

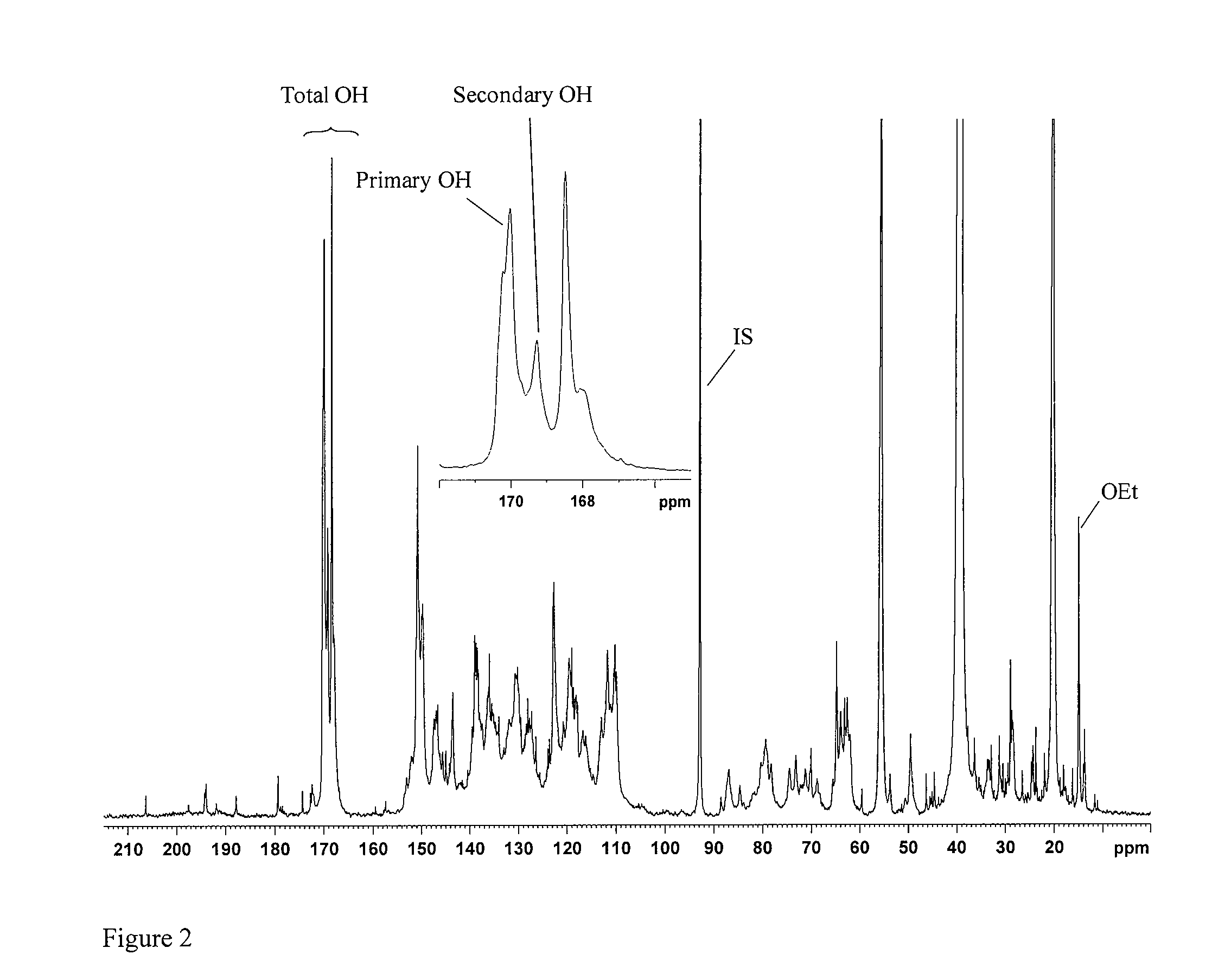

ActiveUS8431635B2Consistent and predictable antioxidant activityConsistent activityNatural cellulose pulp/paperWood working apparatusSoftwoodPolymer composition

One aspect of the invention relates to softwood lignin derivatives having an aliphatic hydroxyl content of from about 2.5 mmol / g to about 7 mmol / g lignin, and the preparation method thereof. The lignin derivatives have a desired antioxidant activity characterized by radical scavenging index (RSI). Another aspect of the invention relates to compositions comprising the softwood lignin derivative. Another aspect of the invention relates to a use of the softwood lignin derivatives comprising incorporating the softwood lignin derivatives into polymer compositions.

Owner:SUZANO CANADA INC

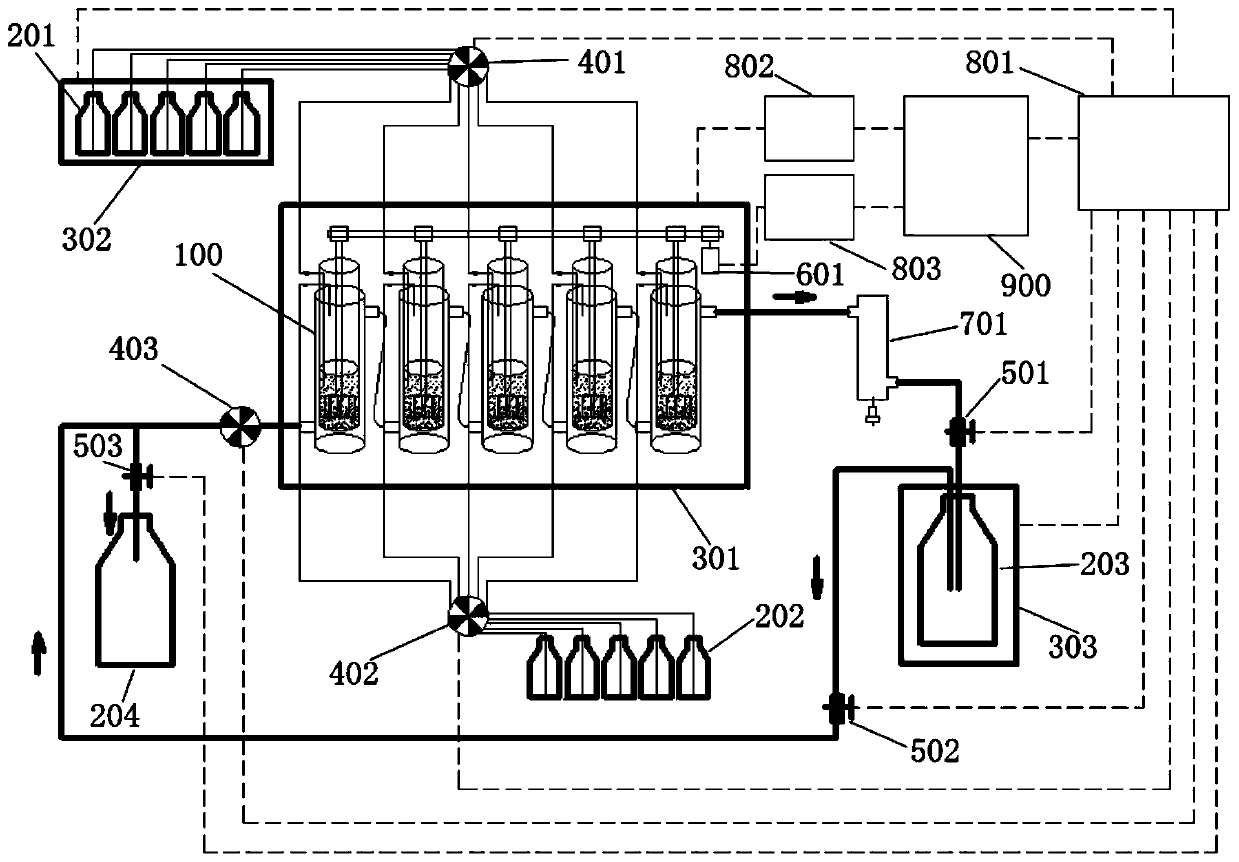

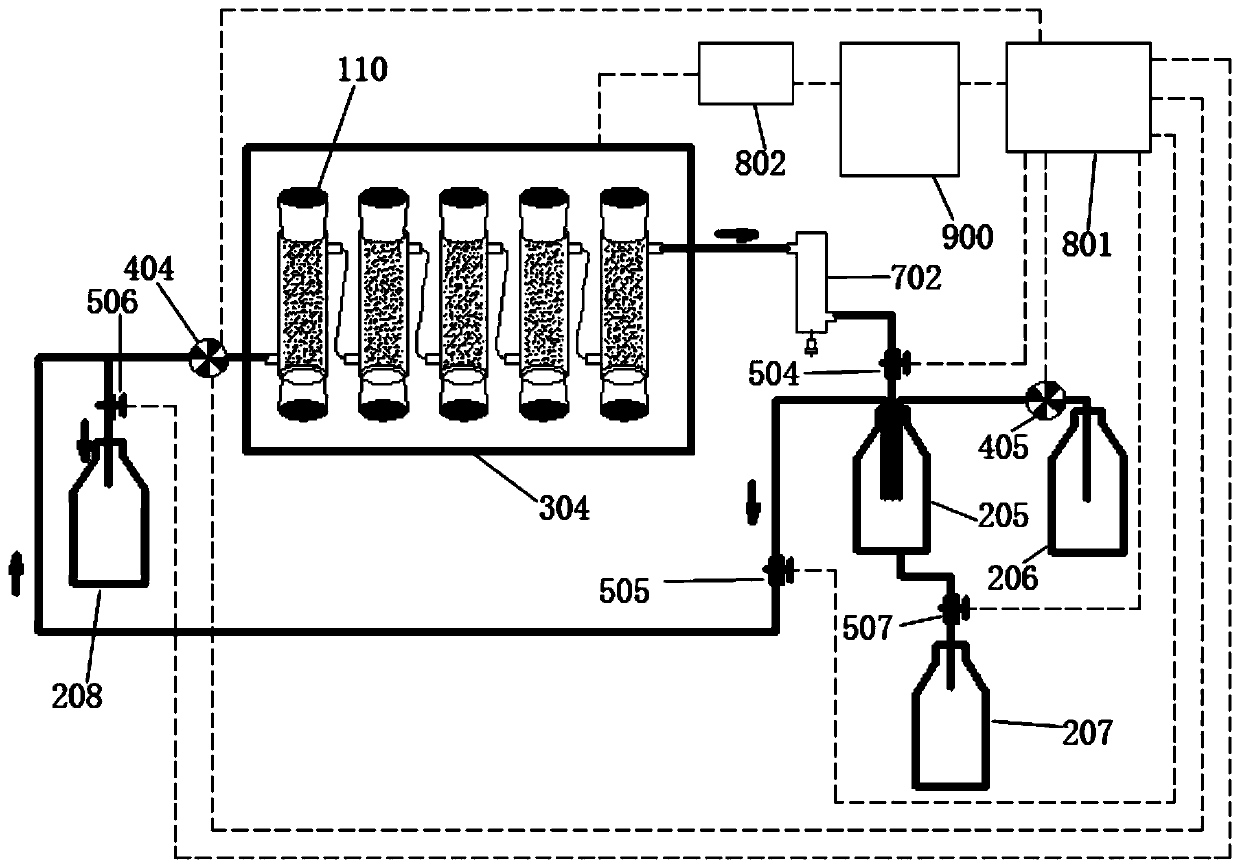

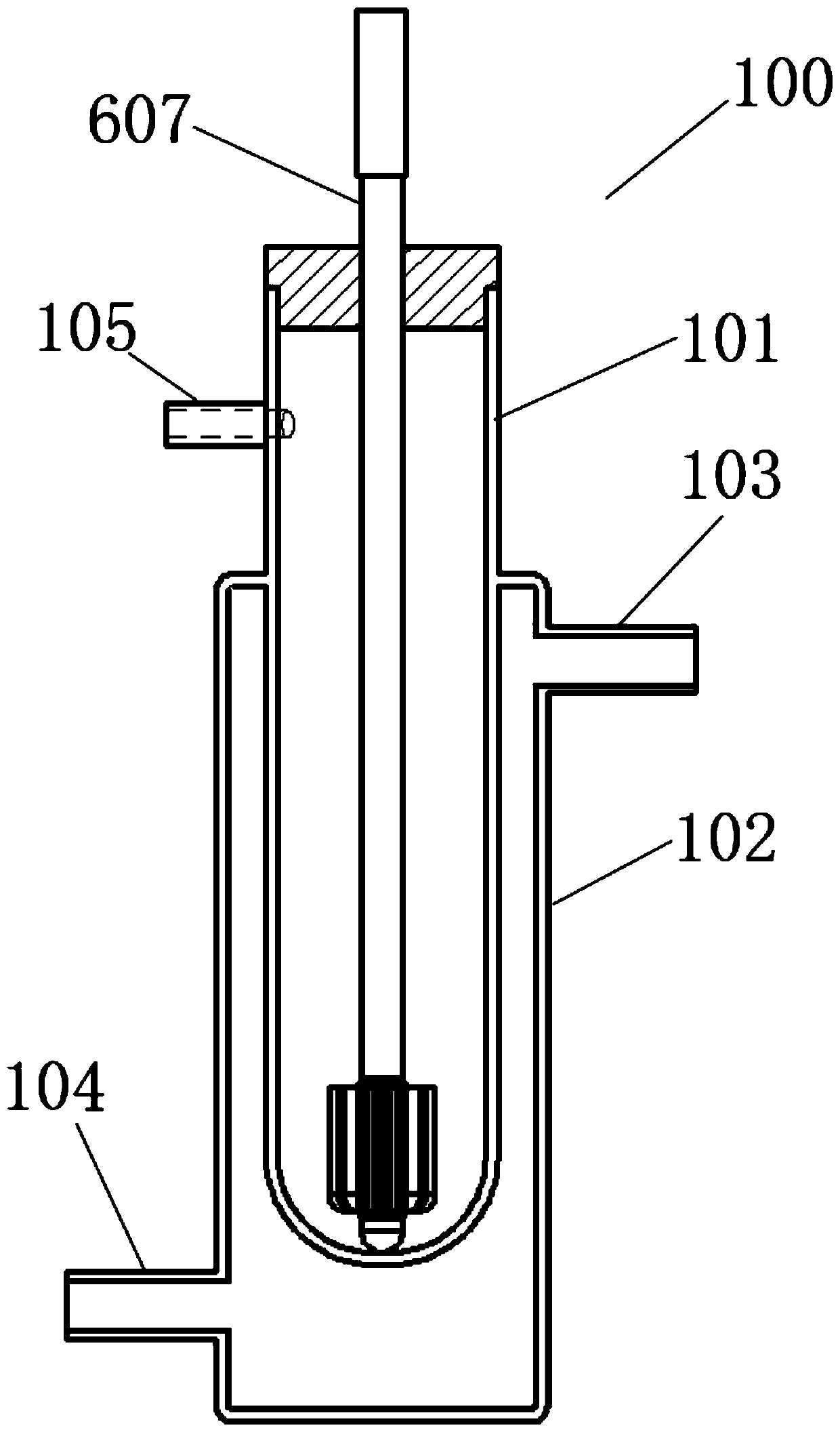

Program-controlled pig bionic digestion system and method using program-controlled pig bionic digestion system to quickly determining digestible energy value of pig feed

ActiveCN110057964AReal Digestion ApproachingConsistent activityChemical methods analysisGastric digestionAnimal science

The invention discloses a program-controlled pig bionic digestion system and a method using the program-controlled pig bionic digestion system to quickly determining a digestible energy value of pig feed. The method comprises the following steps that a feed sample is pulverized and sieved through a standard sieve; a gastric buffer solution and an intestinal buffer solution are prepared; simulatedgastric juice, simulated small intestinal juice and simulated large intestinal juice are prepared; the pulverized feed sample is filled into a simulated digester of the program-controlled pig bionic digestion system, and the simulated gastric juice is added in sequence through computer program control to simulate gastric digestion; after the intestinal buffer solution is added, the simulated smallintestinal juice is added to simulate small intestinal digestion; the simulated large intestinal juice is added to simulate large intestinal digestion; inactivation is carried out after the digestionis completed; and then cleaning is carried out, after undigested residues are obtained, a total energy value of the residues and the feed sample is tested, and the digestible energy value of the feedis calculated. The method is simple, high in precision, low in implementation cost, and the digestible energy value of the pig feed can be accurately determined within 72 hours.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

Preparation method of palladium nitrate solution

InactiveCN106430334ASimple and efficient operationShort processPhysical/chemical process catalystsRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsSolventIon content

Provided is a preparation method of a palladium nitrate solution. The method comprises the steps that 1 part by volume of concentrated nitric acid and 4 parts by volume of concentrated hydrochloric acid are taken and mixed to prepare a solvent A which is used for dissolving metal palladium powder, after the metal palladium powder is completely dissolved, denitration is conducted, hydrazine hydrate is added for reduction, palladium black is obtained, the palladium black is put into a reactor, deionized water and concentrated nitric acid are added for dissolving, cooling is conducted to reach the room temperature, filtration is conducted, and the palladium nitrate solution is obtained. The preparation method is easy to implement, short in technological process, high in production efficiency and good in product consistency, the dissolving rate of metal palladium is high and exceeds 99.5%, the chlorine ion content of the obtained palladium nitrate solution is extremely low, and palladium nitrate catalyst poisoning can be effectively avoided.

Owner:CHONGQING MATERIALS RES INST

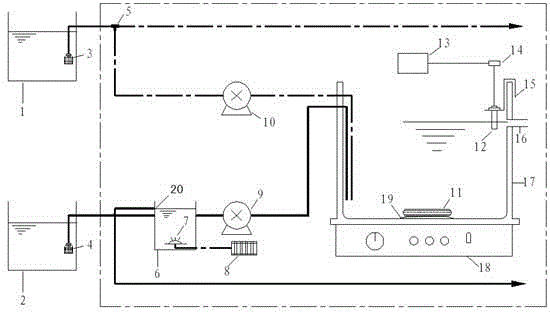

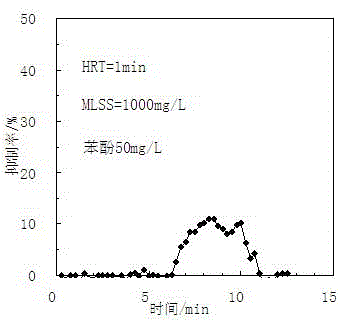

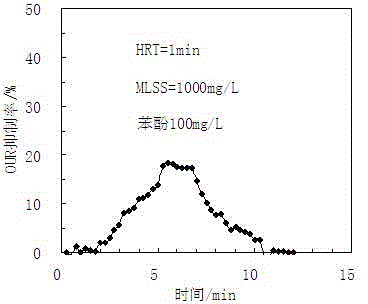

Method for monitoring toxicity of flooding water of municipal sewage plant

InactiveCN103336028ASave power costConsistent activityMaterial analysis by electric/magnetic meansActivated sludgeMunicipal sewage

The invention discloses a method for monitoring toxicity of flooding water of a municipal sewage plant. Mixed liquor of a biochemical pool and flooding water of a sand setting pool of the municipal sewage plant are continuously collected and then mixed according to certain proportion, the respiratory rate of the mixed liquor is measured continuously, and the toxicity and containment degree of the flooding water on the activated sludge of the biochemical pool can be judged through the change of the respiratory rate. According to the method, the toxicity of the flooding water can be monitored continuously online, so that the containment condition of the flooding water on the activated sludge of the biochemical pool can be reflected truly, and the method is less in maintenance, is convenient to operate, and can be applied to an actual sewage treatment plant.

Owner:江西同灿环保科技有限公司

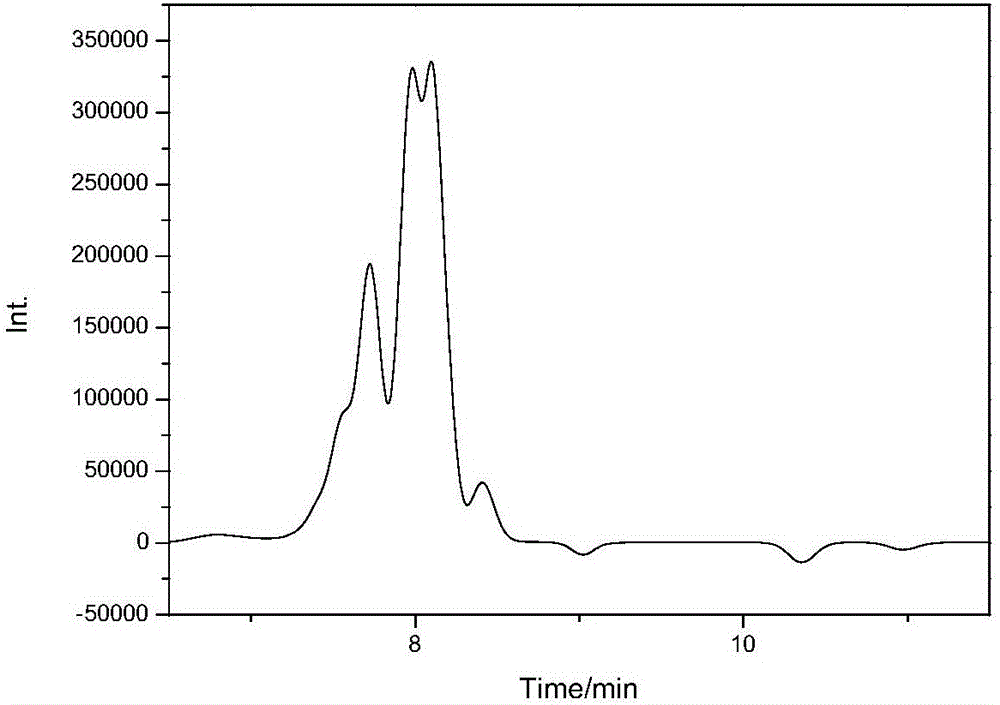

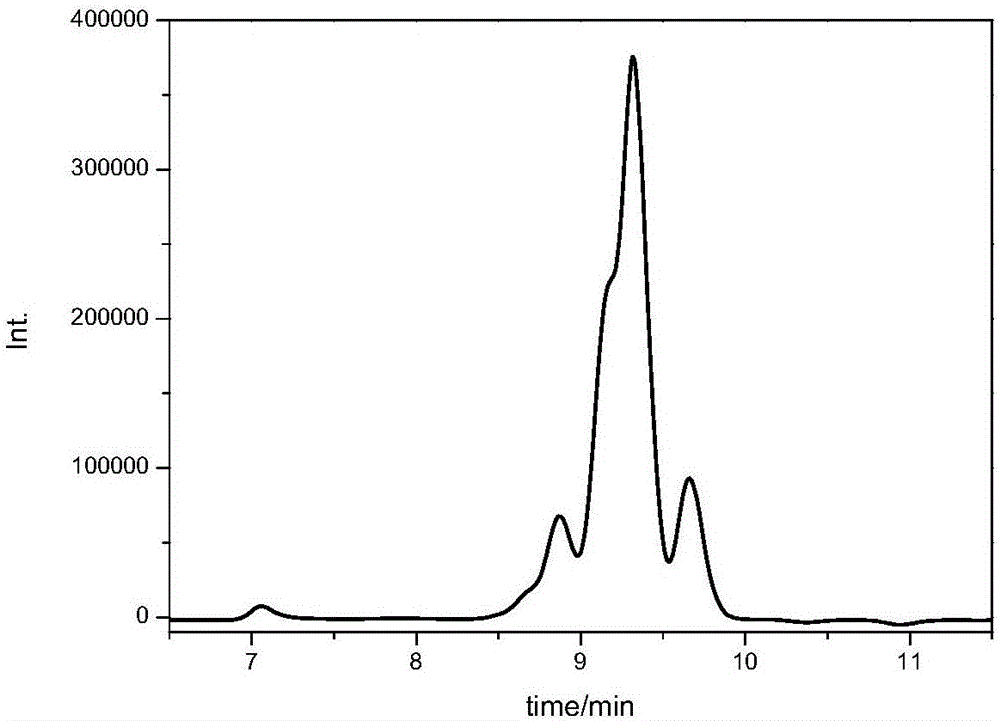

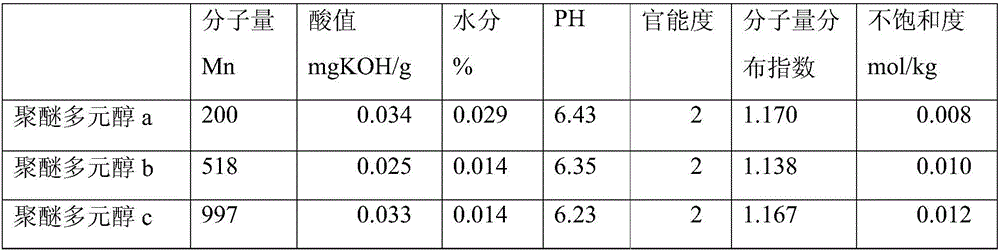

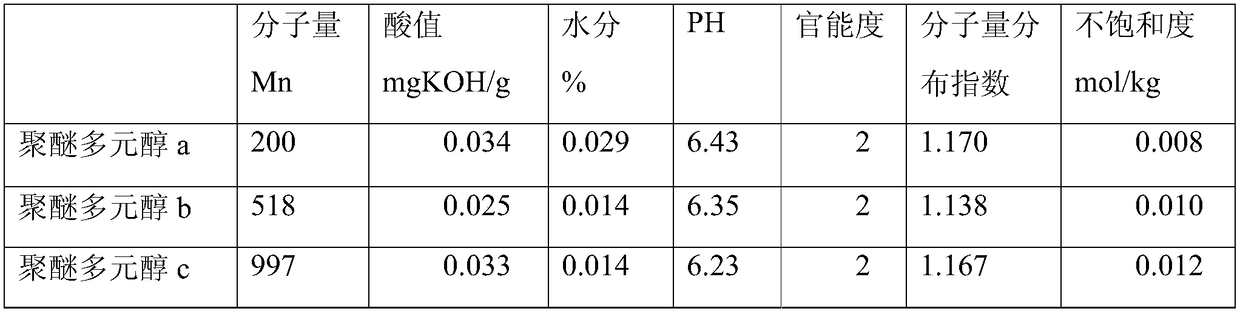

Preparation method preparation method of low-molecular-weight polyether polyol for polyetheramine

ActiveCN106242954AHigh viscosityLow melting pointEther preparation from oxiranesStructural regularityPolyol synthesis

The invention belongs to the technical field of polyether polyol synthesis and specifically relates to a preparation method of low-molecular-weight polyether polyol for polyetheramine. According to the preparation method, 2-methyl-1,3-propylene glycol, which is used as a starting agent, reacts with epoxide in the presence of an alkali metal catalyst at low temperature; and then, the reaction product is end-capped with epoxypropane at high temperature so as to obtain low-molecular-weight polyether polyol for polyetheramine. During the polymerization, 2-methyl-1,3-propylene glycol is used as the starting agent. Due to structural regularity and symmetry of 2-methyl-1,3-propylene glycol, activities at two ends are identical. During polymerization between 2-methyl-1,3-propylene glycol and the epoxide, polyether structure is more regular. During amino-capping, activities at two ends are consistent. The product has characteristics of amorphism, strong weatherability, tension resistance, strong bending resistance and the like. By the structure, polyetheramine can be endowed with characteristics of low melting point, low viscosity and good intersolubility with auxiliaries.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

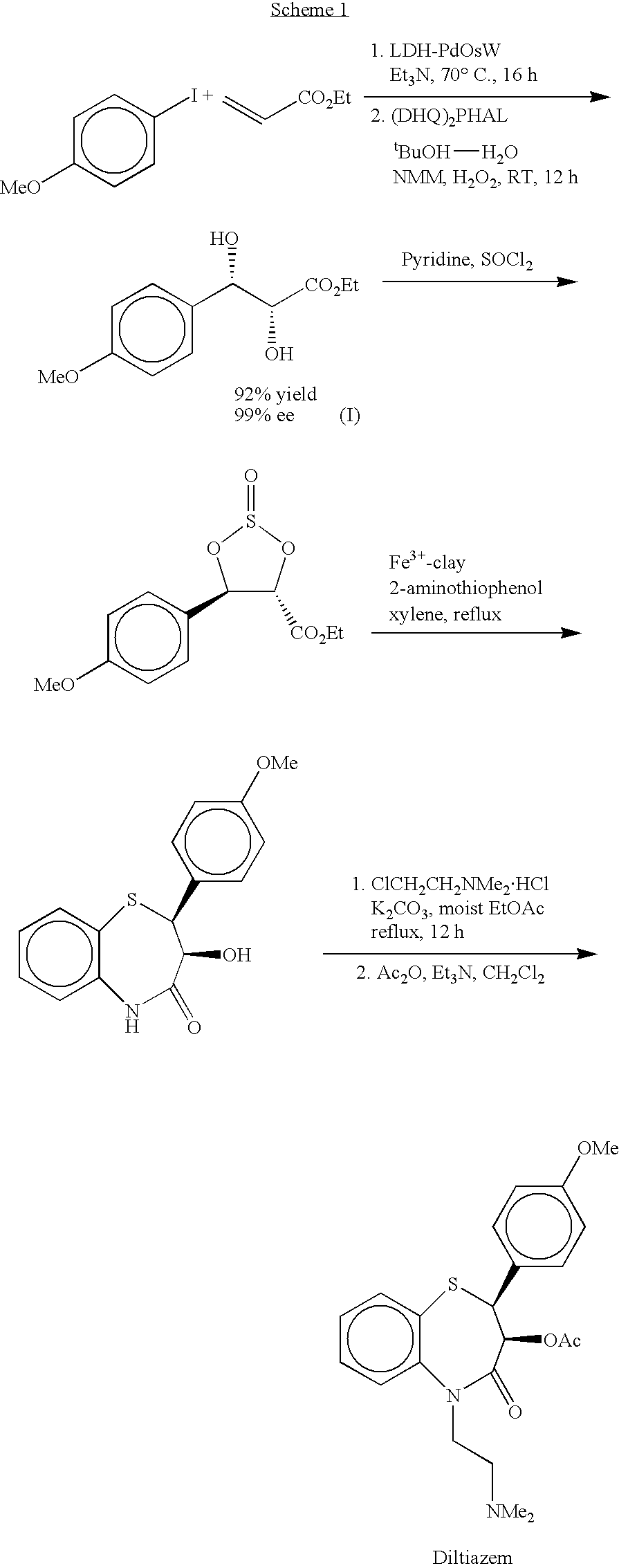

Process for preparing diltiazem using a heterogeneous trifunctional catalyst

InactiveUS20040127704A1High enantioselectivityHigh yieldOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalysts2-AminothiophenolIon exchange

Owner:COUNCIL OF SCI & IND RES

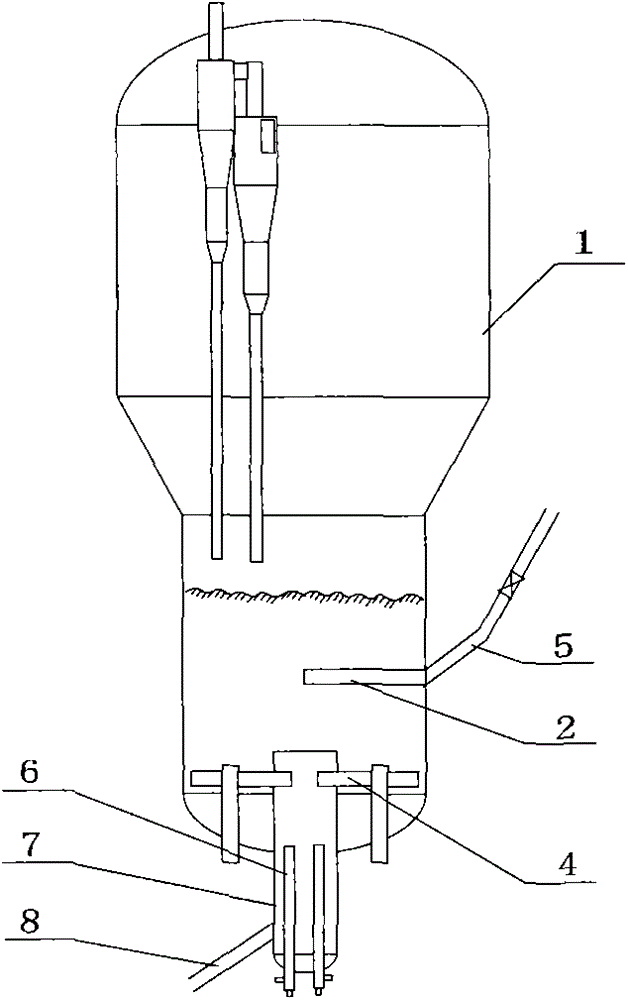

Catalyst regeneration method and regenerator

InactiveCN104415798ASame burn timeConsistent carbon contentCatalyst regeneration/reactivationPetrochemicalEngineering

The invention provides a catalyst regeneration method, belonging to the technical field of petrochemical engineering and fluidization and aiming to improve the burning efficiency of a fluidized bed regenerator. The catalyst regeneration method comprises spent catalyst feeding, main air feeding, fluidized bed burning and regenerating agent discharging, and is characterized in that a turbulent flow bed is in reverse contact to be burnt; a spent catalyst passes through the distributor to enter from the upper part of a fluidized bed and is distributed; a regenerating agent is led out from the central position of the lower part of the fluidized bed; and heating is set so that the temperature of the regenerating agent is lowered and the agent-oil ratio of the device is improved. According to the method, the burning time of the spent catalyst in the fluidized bed can be consistent, the carbon content of the regenerating agent is consistent, the activity of the regenerating agent is consistent, the temperature of the regenerating agent is lowered and the agent-oil ratio of the device is improved. The invention further provides regenerator which can be used for realizing the method and is composed of a central leading-out pipe, a regenerating agent conveying pipe, a spent catalyst feeding pipe and a spent catalyst lifting pipe. The catalyst regeneration method is applied to catalytic cracking and methanol-to-olefin device regenerators.

Owner:刘英聚

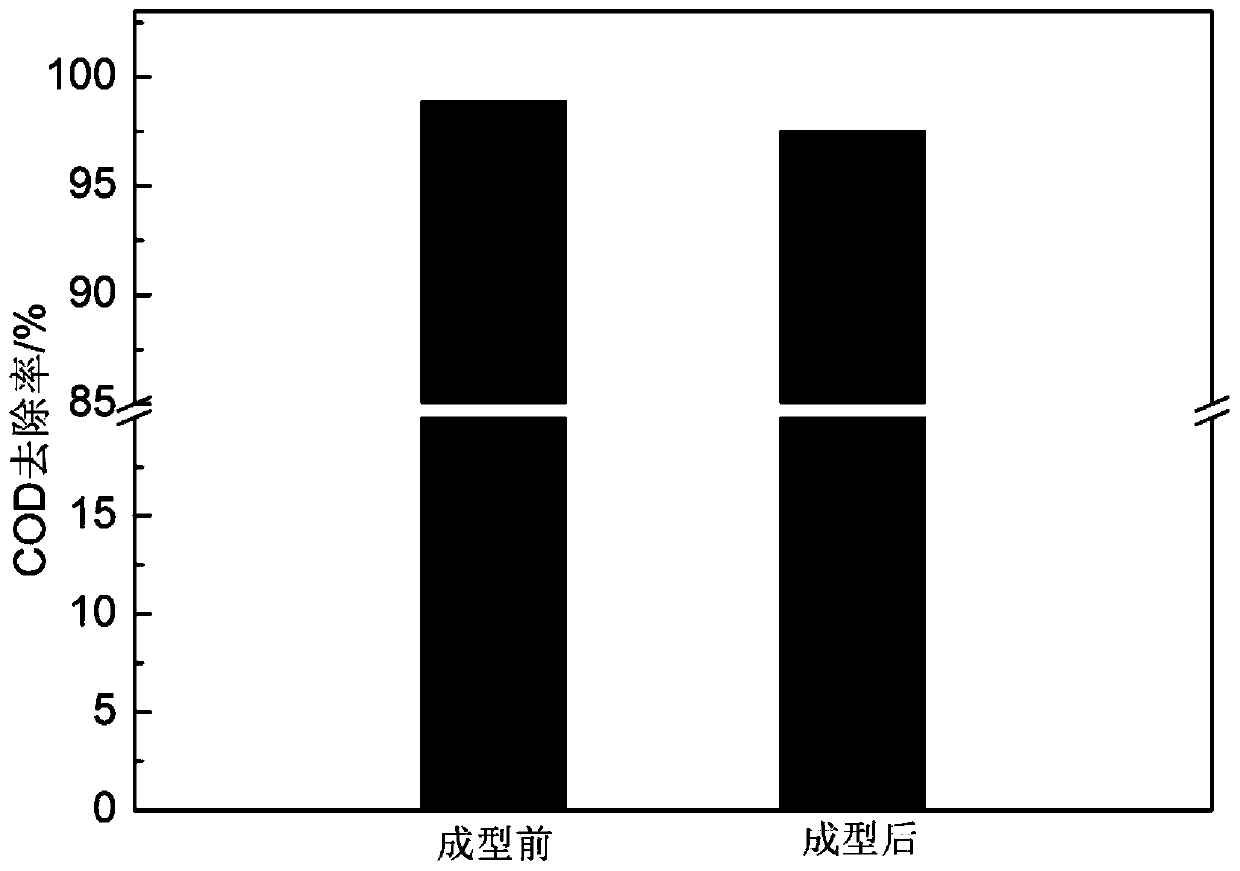

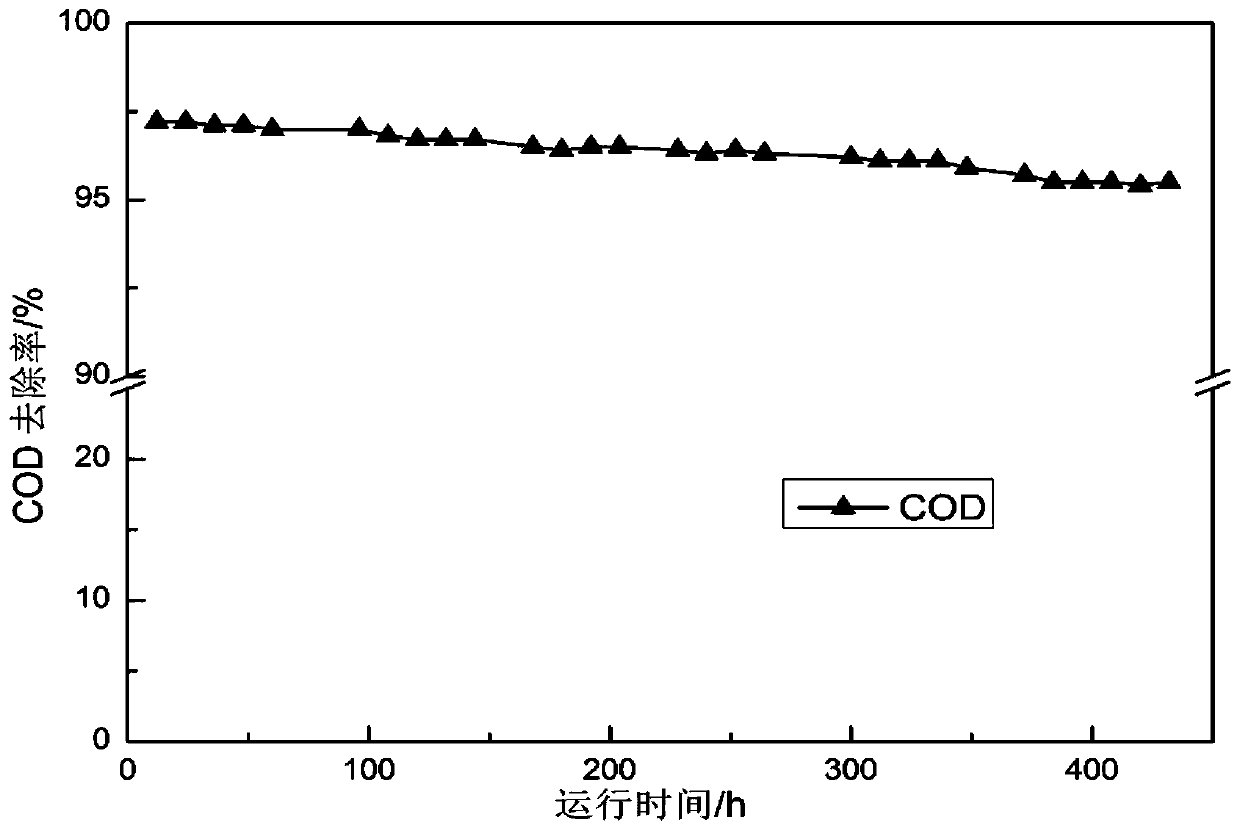

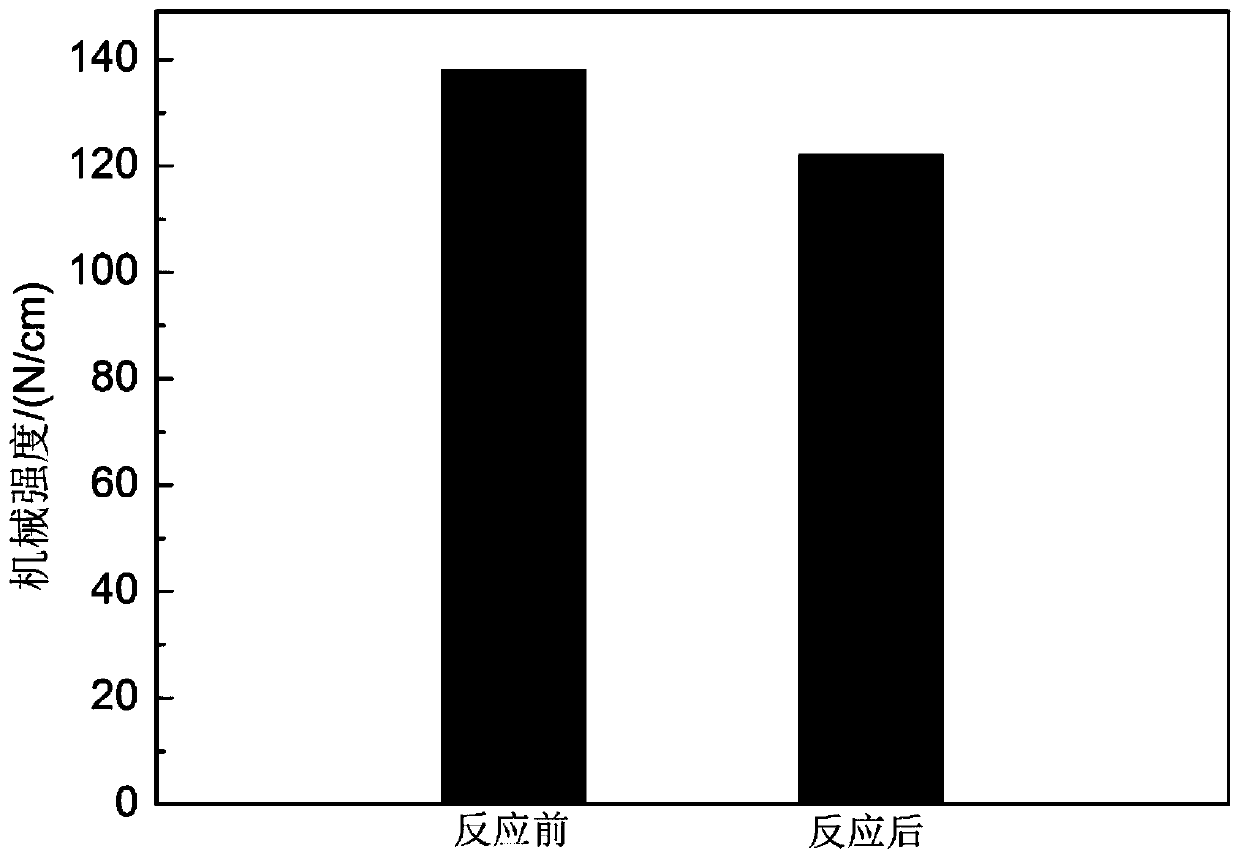

Method for molding catalyst applied to catalytic wet oxidation

InactiveCN110252284AHigh hydrothermal stabilityConsistent activityWater/sewage treatmentWaste water treatment from textile industryIndustrial reactorUltimate tensile strength

The invention provides a method for molding a catalyst applied to catalytic wet oxidation, belonging to the technical field of wastewater treatment. The method is applied to a powder catalyst which can be applied to various industrial reactors only after molding. The method is characterized in that the powder catalyst is a transition metal powder catalyst; and in the process of molding, auxiliary binders, a squeezing agent and a pore structure modifier are added at first, then a binder is dropwise added while mixing and kneading, and then extrusion molding, drying and roasting are performed. According to the invention, a silica sol is added as the binder and nanometer ZrO2 and nanometer TiO2 are added as the auxiliary binders, so the hydrothermal stability of the catalyst can be effectively improved while the requirement on mechanical strength during industrial application of the catalyst is met; and the catalyst has almost the same activity before and after molding, and produces good COD removal effect on wastewater.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrogenation method of coal tar

ActiveCN104593058AConsistent activityEasy to removeTreatment with hydrotreatment processesMolecular sievePtru catalyst

The invention discloses a hydrogenation method of coal tar. The method includes performing hydrogenation modification of the coal tar raw material, separating to remove water, and performing hydrofining and fractionation to obtain a gasoline fraction, a diesel oil fraction and a hydrogenation tail oil, wherein a catalyst applied in the hydrogenation modification process comprises ferric oxyhydroxide, organic polybasic carboxylic acid, macroporous alumina, molecular sieve and pseudo-boehmite. The inventive method adopting the hydrogenation modification catalyst with the low-cost ferric oxyhydroxide as an active metal component has low cost, and can realize moderate cracking and refining of the coal tar, effectively remove impurities in the coal tar, adjust product distribution and properties, and extend running cycle of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

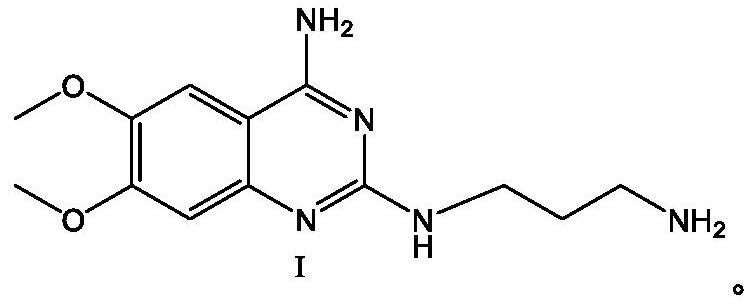

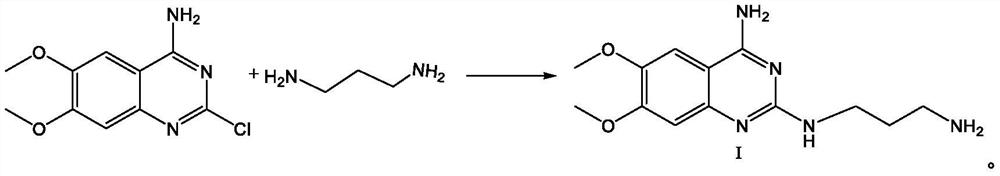

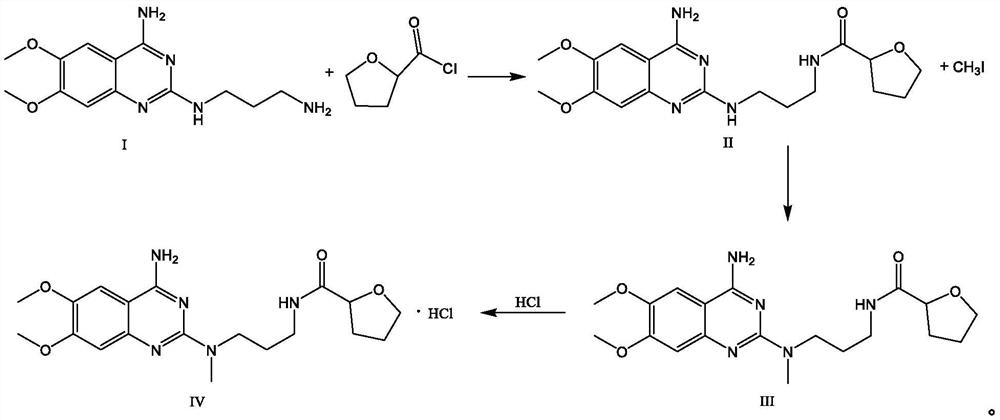

Alfuzosin hydrochloride intermediate compound

PendingCN113801069ASimple and fast operationOperational securityOrganic chemistryPropionitrileCombinatorial chemistry

The invention belongs to the technical field of medicine synthesis, and particularly relates to an alfuzosin hydrochloride intermediate compound I and a preparation method thereof. 3-methylaminopropionitrile commonly used in the alfuzosin hydrochloride synthesis process is replaced with 1, 3-propane diamine. As the activities of two amino groups are consistent, the selectivity problem does not exist, and side reactions are few. Meanwhile, a high-temperature and high-pressure cyano reduction reaction is avoided. A method for preparing alfuzosin hydrochloride by using the intermediate is simple and convenient to operate, low in cost, high in yield and purity and suitable for large-scale industrial production.

Owner:LUNAN PHARMA GROUP CORPORATION

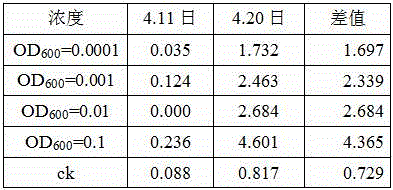

Method of quantitatively evaluating cucumber green mottle mosaic virus resisting ability of Lagenaria leucantha

InactiveCN106818455AGuaranteed singularityConsistency concentrationPlant genotype modificationMaterial analysisGerm plasmLagenaria

The invention relates to the technical field of crop disease resistance and breeding, in particular to an inoculation identification and quantitative detection method of cucumber green mottle mosaic viruses of Lagenaria leucantha. A method of quantitatively evaluating the cucumber green mottle mosaic virus resisting ability of Lagenaria leucantha comprises the following steps: firstly, utilizing bacterial liquid carrying an infectious cloning vector to inoculate Lagenaria leucantha seedlings by a cotyledon pressing contact method, then detecting CGMMV absorption values in a Lagenaria leucantha plant within two time quantum after inoculation by utilizing an ELISA technology, and comprehensively evaluating the ability of resisting CGMMV of different Lagenaria leucantha germ plasm according to the content variation condition of the CGMMV. Therefore, the method replaces phenotypic identification based on disease symptoms and is simple to operate and liable to apply.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

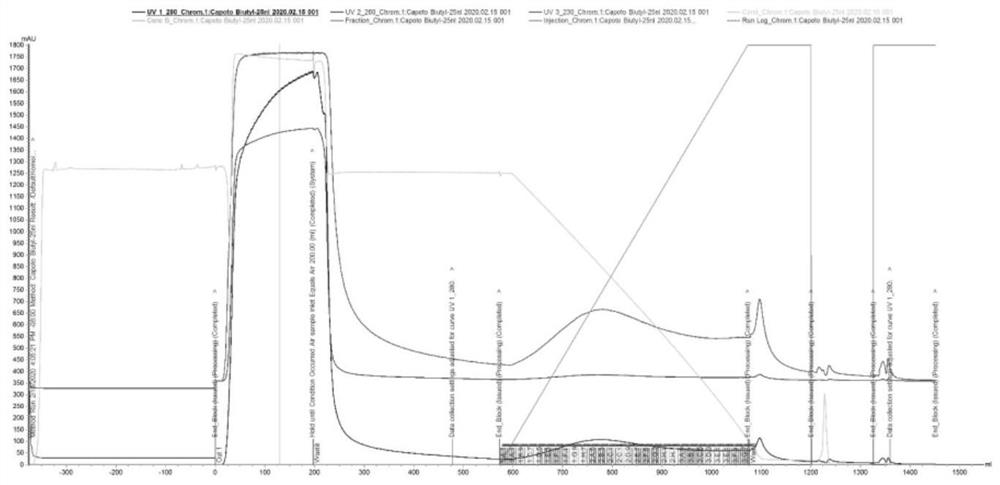

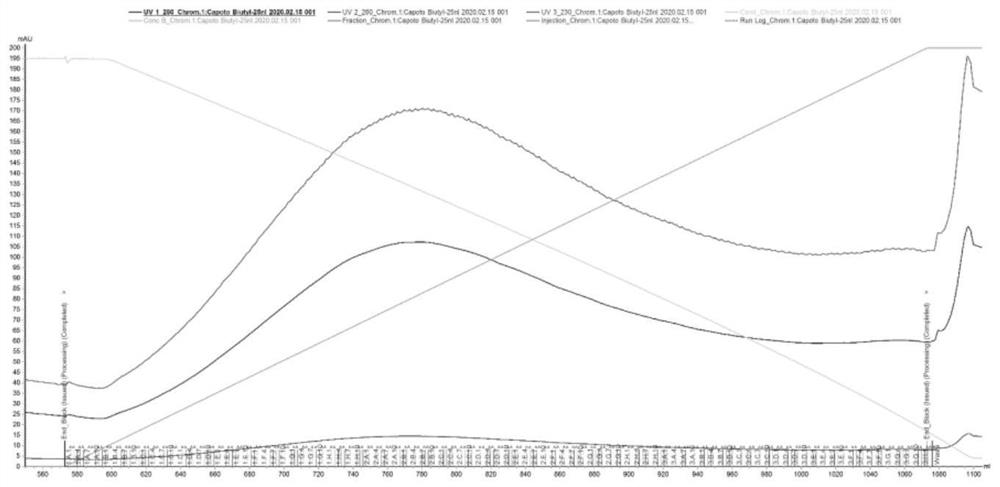

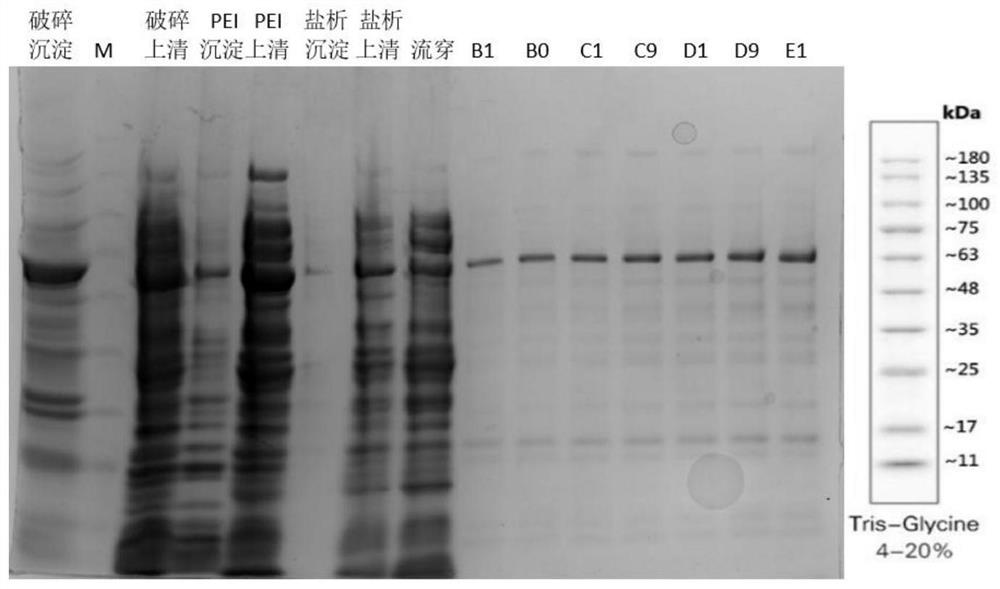

M-MLV reverse transcriptase and preparation method thereof

PendingCN114214299AHigh purityIncrease enzyme activityTransferasesNucleic acid vectorEscherichia coliGene Mutant

The invention discloses an M-MLV reverse transcriptase and a preparation method thereof. A reverse transcriptase gene sequence containing M-MLV is constructed, the reverse transcriptase gene sequence is connected to a vector and then is introduced into escherichia coli for expression, and a gene mutation site contains one or more of D524G, E562Q, D538N and G638H. According to the present invention, the amino acid of the mutation key site is charged or the hydrophobicity is changed so as to change the space structure of the M-MLV reverse transcriptase, weaken the M-MLV RNase H Minus, and improve the activity and the stability of the M-MLV reverse transcriptase;

Owner:苏州译酶生物科技有限公司

Trichloroacetone production process

InactiveCN108752176AHigh hydroxyl contentHigh selectivityCarbonyl compound separation/purificationPreparation from heterocyclic compoundsBenzeneAlcohol

The invention relates to the technical field of chemical production and in particular relates to a trichloroacetone production process. According to the process, the content of trichloroacetone in thecrude product obtained by one-step production of trichloroacetone can be obviously improved, and the product purity is improved. The process specifically comprises the following steps: S1, mixing acetone and ethylene glycol, adding an accelerant into the mixture, heating and stirring uniformly, and carrying out an addition reaction; S2, introducing chlorine into the mixture prepared in the S1, adding a catalyst, uniformly stirring and mixing, and carrying out a chlorination reaction; S3, adding an acid into the mixture prepared in the S2 for hydrolysis, and preparing the crude trichloroacetone; S4, performing the first purification on the crude trichloroacetone prepared in the S3 with water; S5, continuously performing the second purification on the crude trichloroacetone with benzene; S6, performing the third purification on the crude trichloroacetone with alcohol; S7, recrystallizing the product treated in the S6, thereby obtaining the final product trichloroacetone.

Owner:枣阳天燕硅普材料有限公司

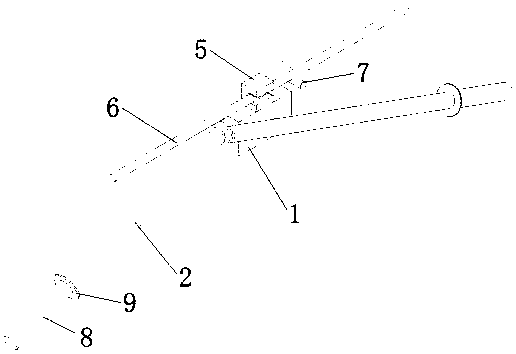

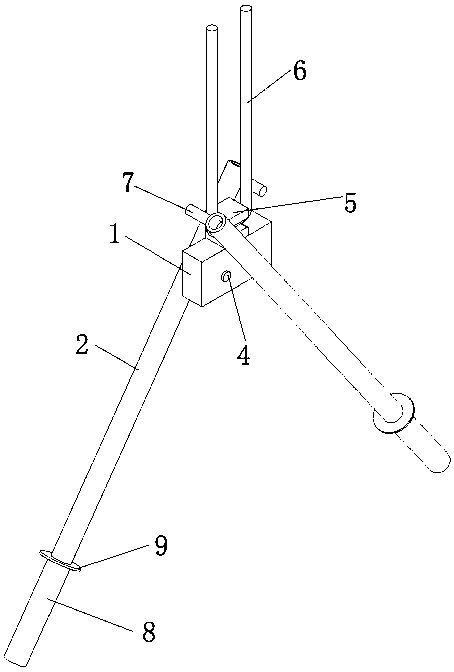

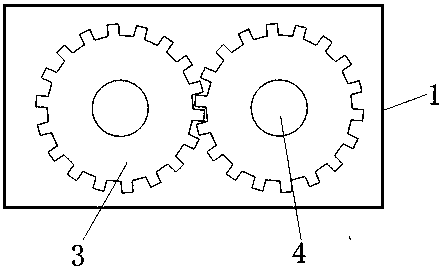

Stay wire bender

PendingCN108493839AApplicable to the production of curved shapes required for pull wiresMade applicableApparatus for overhead lines/cablesFixed positionSteel tube

The invention relates to a tool, in particular to a stay wire bender. The stay wire bender comprises a square aluminum box and steel tubes, wherein the number of the steel tubes is two, the steel tubes form an ''X'' shape by taking the square aluminum box as an intersection, two sets of synchronous gears are arranged in the square aluminum box, a central shaft of each set of synchronous gears passes through through holes on both sides of the square aluminum box so as to fix positions of the gears, the two sets of synchronous gears are engaged by means of toothed slots, one of the steel tubes is perpendicularly connected with the central shaft of one set of the synchronous gears, a steel mold is arranged on the square aluminum box, a groove is formed in the steel mold for clamping a stay wire, one end, connected with the synchronous gears, of the steel tube is welded with a pressing column, and the pressing column is perpendicular to the steel pipe and is used for applying a force to the stay wire so as to bend the stay wire. The stay wire bender can keep the bending shapes of the stay wires consistent, and maintains good bending quality and appearance of the stay wires.

Owner:GUANGDONG POWER GRID CO LTD +1

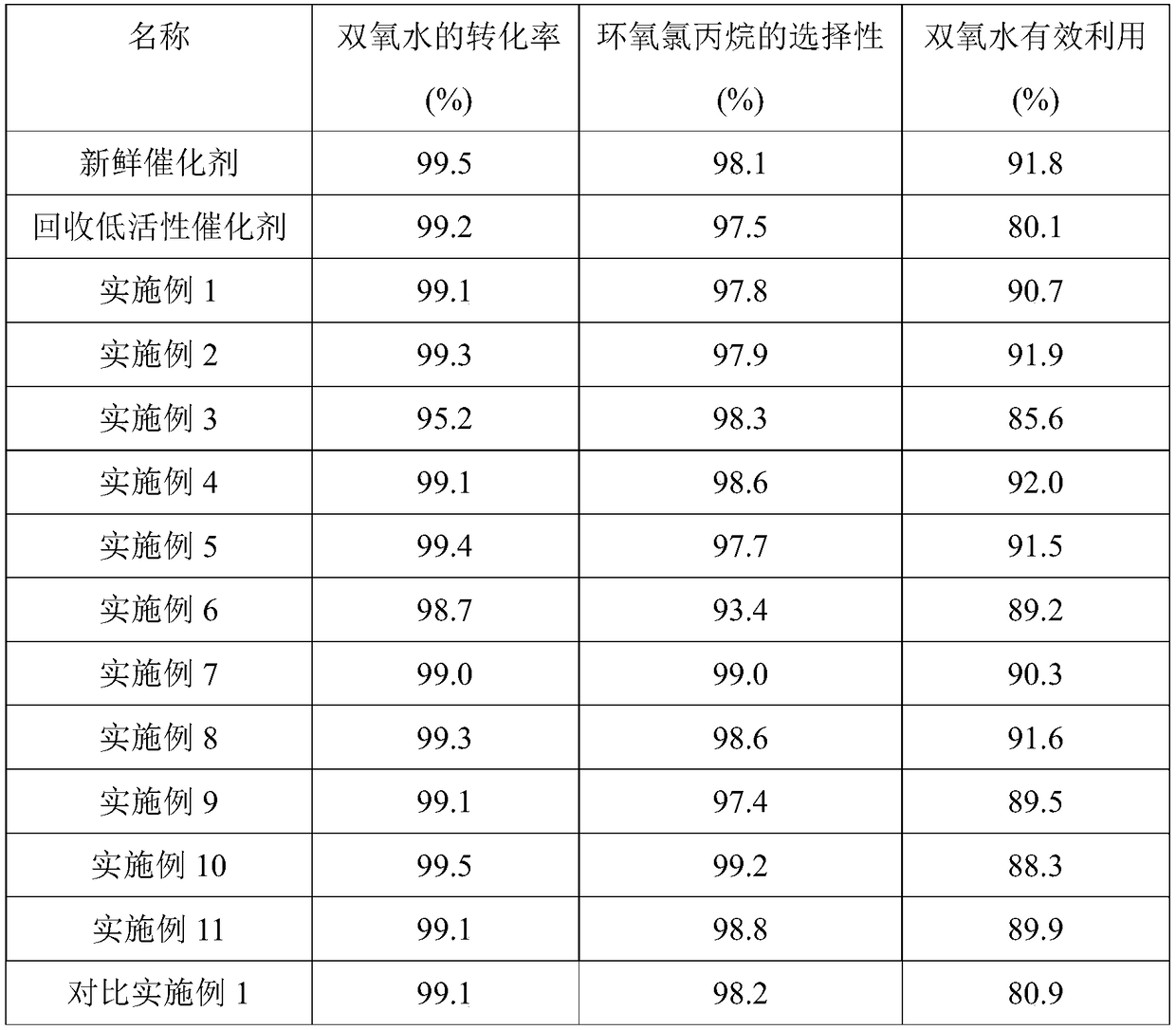

Method for regenerating phosphorus molybdenum/tungsten heteropolyacid quaternary ammonium salt catalyst

ActiveCN108993616AProcess stabilityPromote regenerationOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst regeneration/reactivationAqueous solutionTungsten

The invention discloses a method for regenerating a phosphorus molybdenum / tungsten heteropolyacid quaternary ammonium salt catalyst. The method comprises the following steps: (1) adding equivalent deionized water into a phosphorus molybdenum / tungsten heteropolyacid quaternary ammonium salt catalyst with activity decrease, and oxidizing in an ozone atmosphere; (2) adding water into the oxidized phosphorus molybdenum / tungsten heteropolyacid quaternary ammonium salt catalyst, and stripping under a negative pressure; (3) adding a quaternary ammonium salt aqueous solution into the kettle, stirring,washing and regenerating. The method has the main advantages that (1) the catalyst regeneration process is simple, and the process is stable; (2) the regenerated catalyst and the novel catalyst havebasically consistent activity. The requirements on modern industrial application are met.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Preparation method of low molecular weight polyether polyol for polyether amine

ActiveCN106242954BHigh viscosityLow melting pointEther preparation from oxiranesPolyol synthesisStructural regularity

Owner:SHANDONG INOV NEW MATERIALS CO LTD

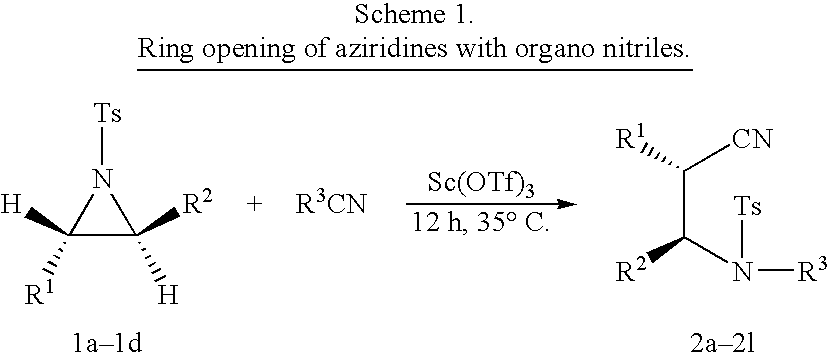

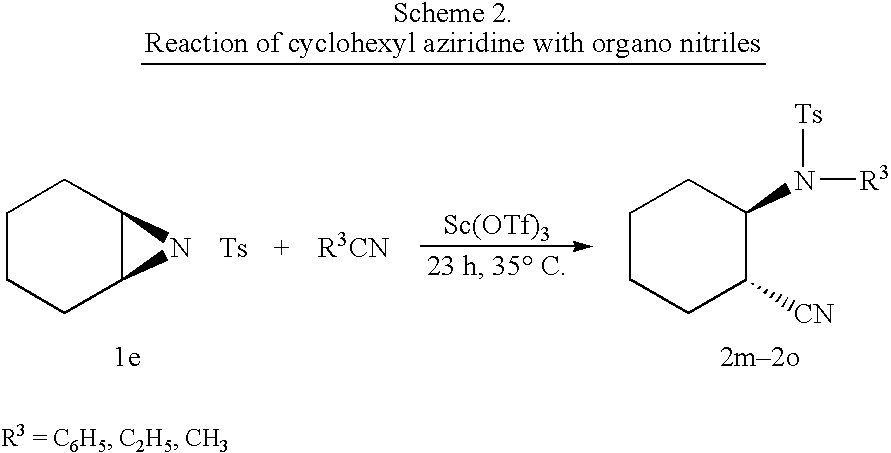

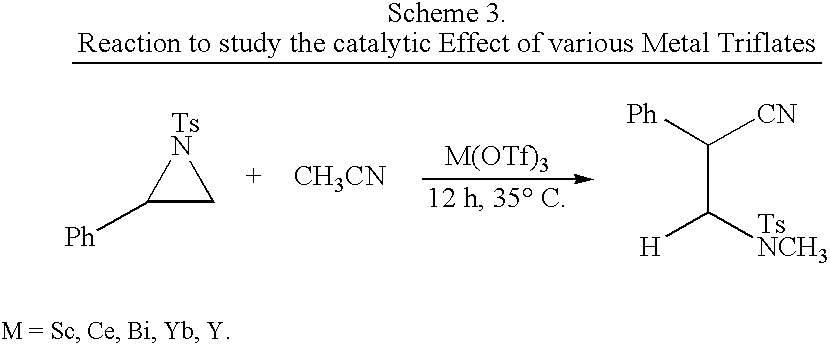

Process for the synthesis of N-Substituted beta-amino nitriles through the ring opening of aziridines

InactiveUS6906216B2High selectivityHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationAziridineTosylhydrazone

Owner:COUNCIL OF SCI & IND RES

High-purity trichloroacetone production technology

InactiveCN108997094AHigh hydroxyl contentHigh selectivityOrganic compound preparationPreparation by halogen introductionBenzeneAlcohol

The invention relates to the technical field of chemical production, in particular to a high-purity trichloroacetone production technology which can significantly increase the content of trichloroacetone in a crude product obtained by one-step production of trichloroacetone and improve the product purity. The technology specifically comprises the following steps: S1: mixing acetone with glycerin,adding a promoter thereto, heating, stirring uniformly, and performing an addition reaction; S2: introducing chlorine into a mixture prepared in the S1, adding a catalyst, stirring, mixing uniformly,and performing a chlorination reaction; S3: adding acid into the mixture prepared in the S2 for hydrolysis to prepare crude trichloroacetone; S4: performing initial purification on the crude trichloroacetone prepared in the S3 with water; S5: continuously performing secondary purification on the crude trichloroacetone with benzene; S6: performing third-time purification on the crude trichloroacetone with alcohol; and S7: recrystallizing a product treated in the S6 to obtain a final product of trichloroacetone.

Owner:枣阳天燕硅普材料有限公司

Process for the preparation of 2-nitrothiophene selectively from thiophene using metal exchanged clay catalysts

InactiveUS20030181734A1High yieldConsistent activityPhysical/chemical process catalystsOrganic chemistry methodsAcetic anhydrideTerthiophene

The present invention provides an ecofriendly process for the preparation 2-nitrothiophenes selectively from thiophene, using metal exchanged clay catalysts and nitric acid, dispensing with the use of acetic anhydride.

Owner:COUNCIL OF SCI & IND RES

Process for the preparation of 2-nitrothiophene selectively from thiophene using metal exchanged clay catalysts

InactiveUS6794521B2High yieldConsistent activityPhysical/chemical process catalystsOrganic chemistry methodsTerthiopheneAcetic anhydride

The present invention provides an ecofriendly process for the preparation 2-nitrothiophenes selectively from thiophene, using metal exchanged clay catalysts and nitric acid, dispensing with the use of acetic anhydride.

Owner:COUNCIL OF SCI & IND RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com