Method for molding catalyst applied to catalytic wet oxidation

A technology for catalyzing wet oxidation and molding methods, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. Preparation procedures, catalyst activity decline and other problems, to achieve good industrial application prospects, good removal effect, and improve the effect of hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

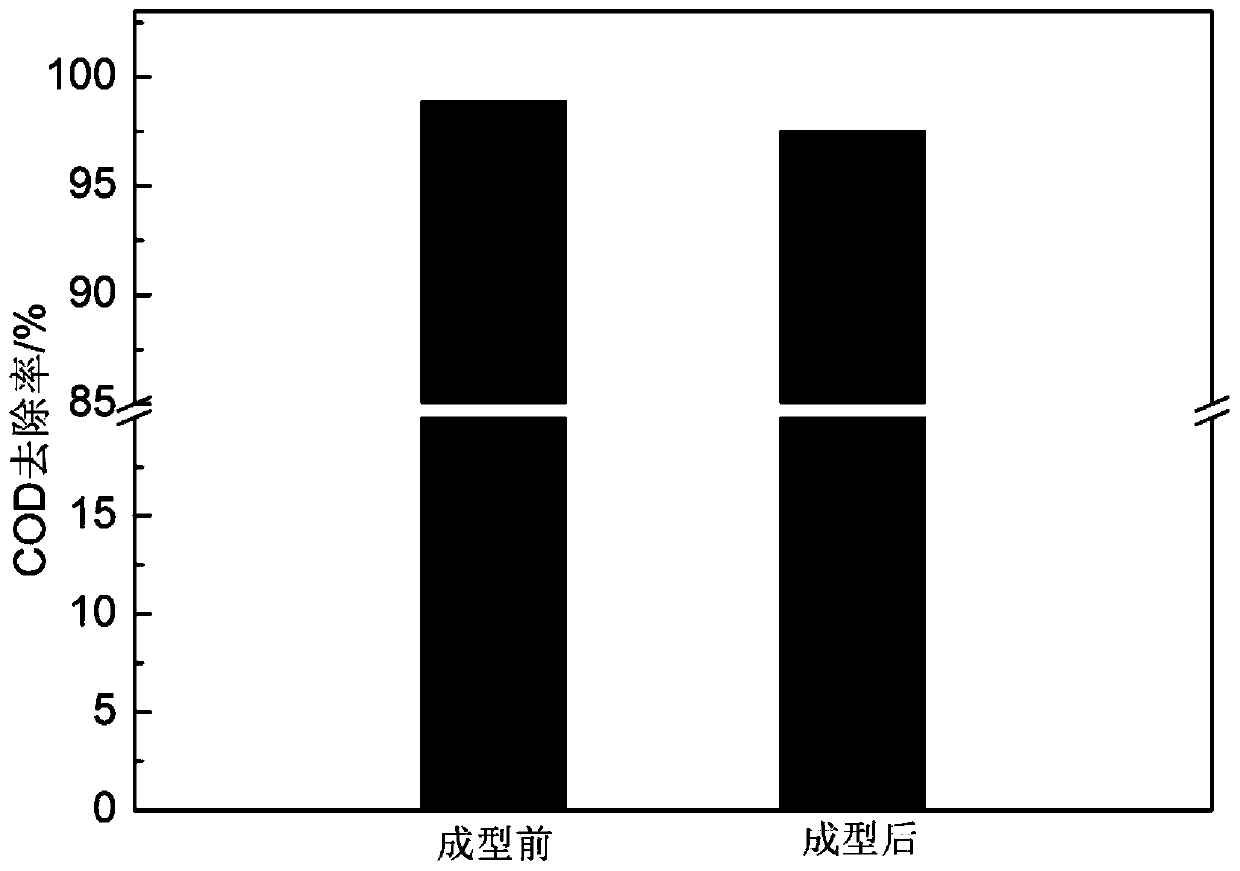

Embodiment 1

[0049] Example 1: A molding method of catalytic wet oxidation catalyst, that is, a molding method of cryptomanganese ore (OMS-2) powder. The transition metal powder catalyst is ground and pulverized to 100-150 mesh cryptomanganese Potassium ore (OMS-2) powder, its weight is 0.8 kg;

[0050] The auxiliary binder is nano ZrO 2 Powder, the weight of which is 0.16 kg;

[0051] Described extruding aid is squash powder, and its weight is 0.016 kg;

[0052] Described pore structure modifier is citric acid, and its weight is 0.032 kg;

[0053] The binder is an aqueous solution of silica sol, and its dropping weight is 1.0 kg;

[0054] Mix the above materials with a mixer, add them into a kneader and knead for 20 minutes after mixing completely, add 30% binder silica sol aqueous solution dropwise while kneading, continue kneading for 20 minutes after the addition is completed, until the material becomes plastic state; The kneaded material was put into the extruder, the twin-screw s...

Embodiment 2

[0057] Example 2: A molding method of catalytic wet oxidation catalyst, that is, a molding method of cryptomanganese ore (OMS-2) powder. The transition metal powder catalyst is ground and pulverized to 100-150 mesh cryptomanganese Potassium ore (OMS-2) powder, its weight is 0.8 kg;

[0058] The auxiliary binder is nano ZrO 2 Powder, the weight of which is 0.24 kg;

[0059] Described extruding aid is squash powder, and its weight is 0.016 kg;

[0060] Described pore structure modifier is citric acid, and its weight is 0.032 kg;

[0061] The binder is an aqueous solution of silica sol, and its dropping weight is 1.2 kg;

[0062] Mix the above materials with a mixer, and then add them into the kneader and knead for 30 minutes, while kneading, add 30% of the binder silica sol aqueous solution dropwise, and continue kneading for 20 minutes after the addition is completed, until the materials are in a plastic state; The kneaded materials were put into the extruder, the twin-scre...

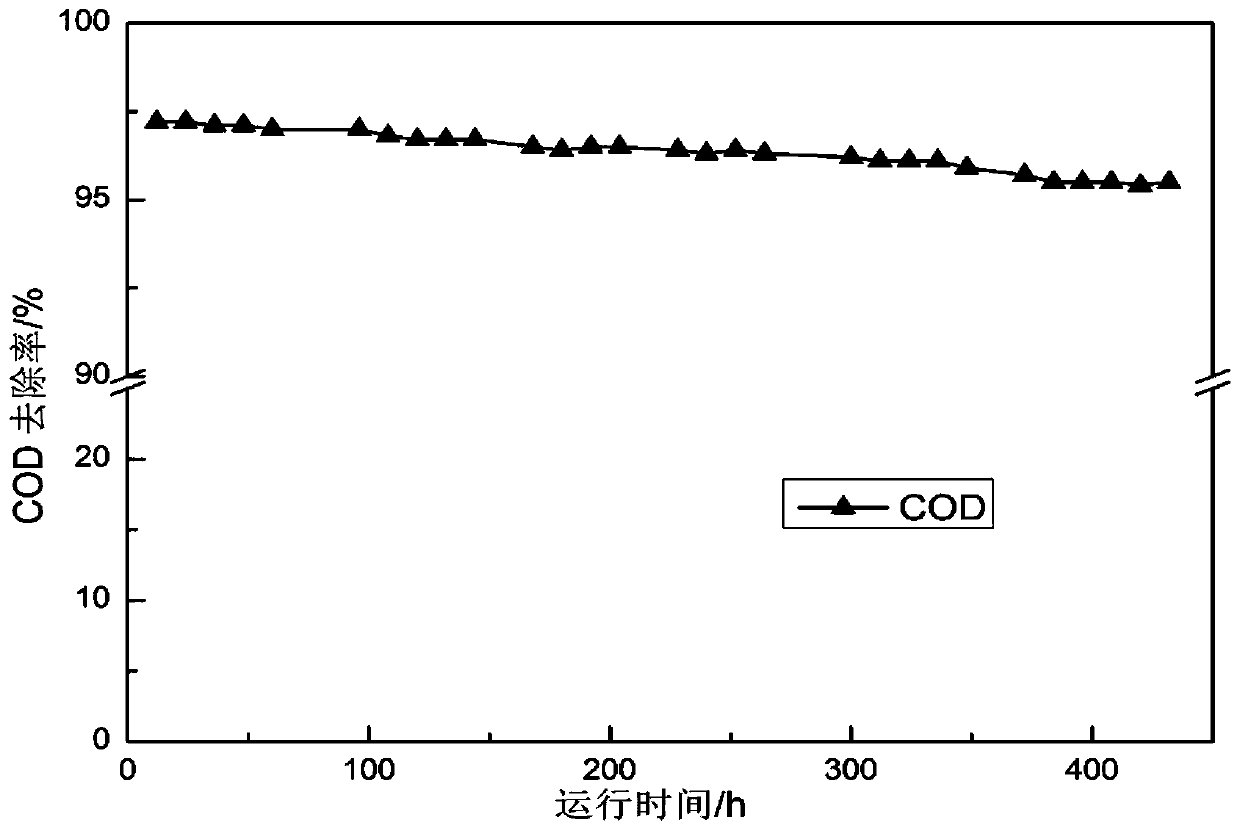

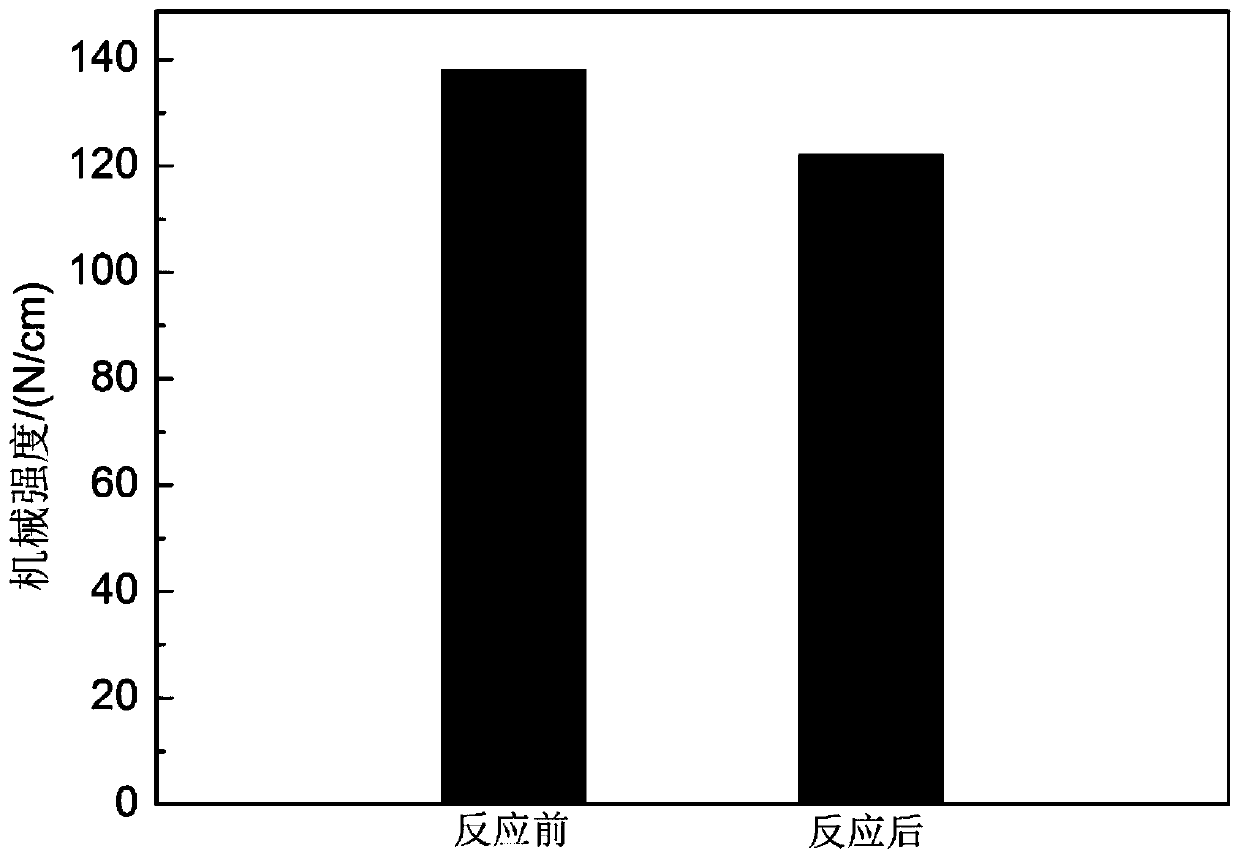

Embodiment 3

[0067] A method for forming a catalytic wet oxidation catalyst, an industrial MnO 2 Powder molding method, the transition metal powder catalyst is ground and pulverized to 100~150 mesh industrial MnO 2 Powder,

[0068] It is a material that is difficult to form. Its weight is 1.5 kg;

[0069] The auxiliary binder is nano TiO 2 Powder, the weight of which is 0.75 kg;

[0070] Described extruding aid is starch, and its weight is 0.075 kg;

[0071] Described pore structure modifier is oxalic acid, and its weight is 0.15 kg;

[0072] The binder is an aqueous solution of silica sol, and its dropping weight is 1.2 kg;

[0073] Mix the above materials with a mixer, and then add them into the kneader and knead for 30 minutes, while kneading, add 30% of the binder silica sol aqueous solution dropwise, and continue kneading for 20 minutes after the addition is completed, until the materials are in a plastic state; The kneaded materials were put into the extruder, the twin-screw s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com