Method for regenerating phosphorus molybdenum/tungsten heteropolyacid quaternary ammonium salt catalyst

A heteropolyacid quaternary ammonium salt and catalyst technology, which is applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low processing efficiency, cumbersome process, long regeneration cycle, etc., and achieve The regeneration process is simple and the process is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

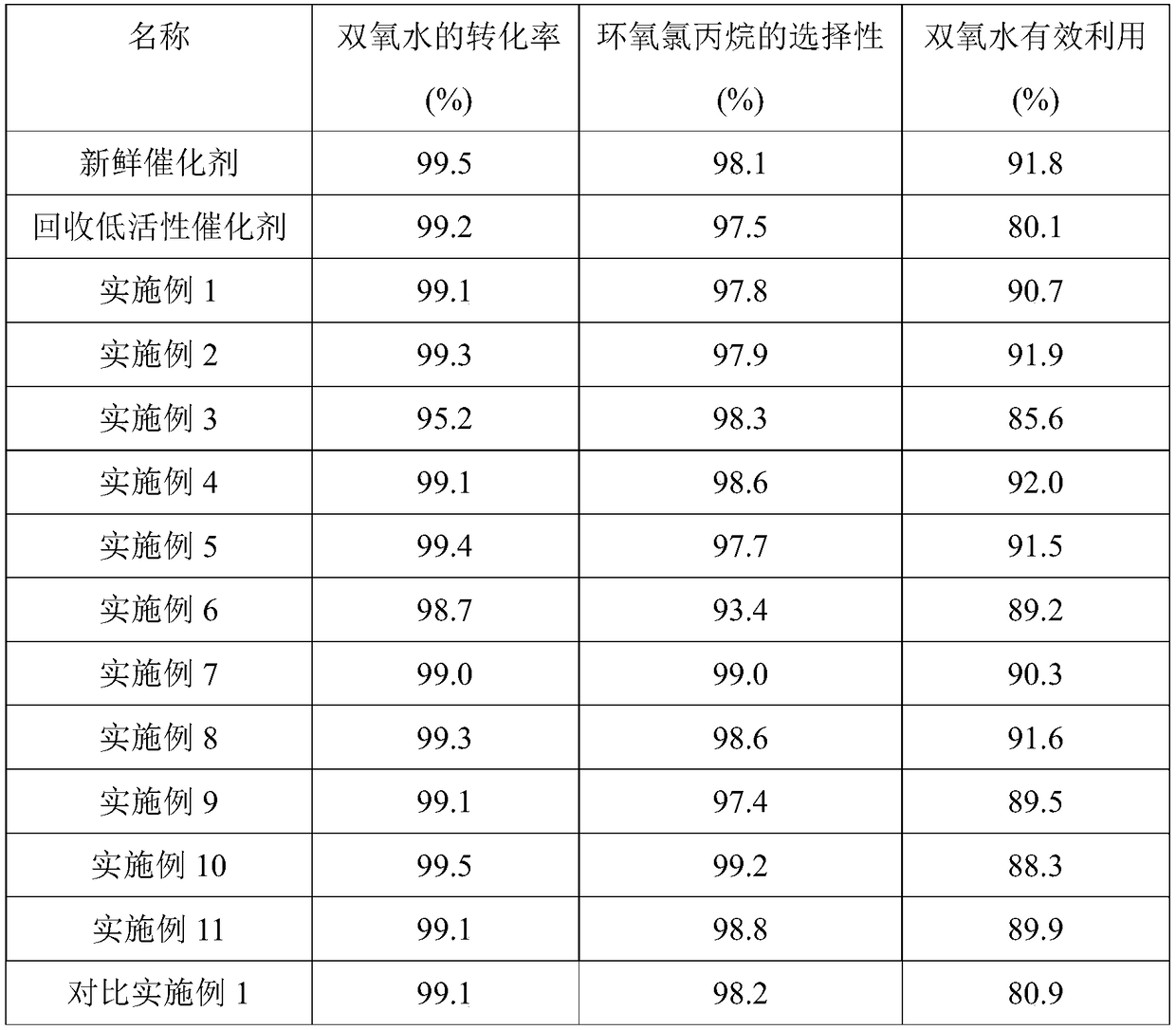

Examples

Embodiment 1

[0022] In the process of preparing epichlorohydrin by direct epoxidation of propylene chloride using aqueous hydrogen peroxide solution as the oxygen source and phosphomolybdenum / tungsten heteropoly acid quaternary ammonium salt as the catalyst, the catalyst will be deactivated or catalytically active as the catalyst is recycled for a certain period of time Reduce to a predetermined level (effective utilization rate of hydrogen peroxide 80.0%). Take 50g of the reduced activity catalyst (phosphomolybdenum / tungsten heteropoly acid quaternary ammonium salt), add 50g of deionized water, at 60℃, pass in the ozone concentration of 12mg / L at a rate of 2.5L / h for 2h; after oxidation Add 250g of water to the catalyst of, and perform stripping at a negative pressure of -0.05Mpa to a temperature of 80℃; add 20.0g of 5.0wt% quaternary ammonium salt aqueous solution to the rest of the reactor, stir and wash at 20℃ to regenerate for 12h, then separate the water after standing. Phase, the bot...

Embodiment 2

[0024] Take 50g of the catalyst with reduced activity and add 50g of deionized water. At 20°C, pass the ozone concentration of 12mg / L at a rate of 2.5L / h to oxidize for 3h; add 500g of water to the oxidized catalyst, and the negative pressure is- Stripping is carried out at 0.07Mpa to a kettle temperature of 70°C; adding 40.0g of a 1.0wt% quaternary ammonium salt aqueous solution to the rest of the kettle, stirring and washing at 30°C for 10h regeneration, after standing still, the water phase is separated, and the bottom solid is the regenerated catalyst.

Embodiment 3

[0026] Take 50g of the catalyst with reduced activity, add 50g of deionized water, and at 70℃, pass the ozone concentration of 12mg / L at a rate of 2.5L / h to oxidize for 5h; add 750g of water to the oxidized catalyst, and the negative pressure is- Stripping is carried out at 0.03Mpa to a kettle temperature of 90°C; 10.0g of a 10.0wt% quaternary ammonium salt aqueous solution is added to the remainder of the kettle, stirred and washed at 50°C for 16h regeneration, after standing still, the water phase is separated, and the bottom solid is the regenerated catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com