Catalyst regeneration method and regenerator

A regenerator and catalyst technology, which is applied in petrochemical and fluidization fields, can solve the problems of long burning time of catalyst, high activity of regenerant, low activity of regenerant, etc., achieve consistent burning time and increase the ratio of agent to oil in the device , Consistent effect of regenerant activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

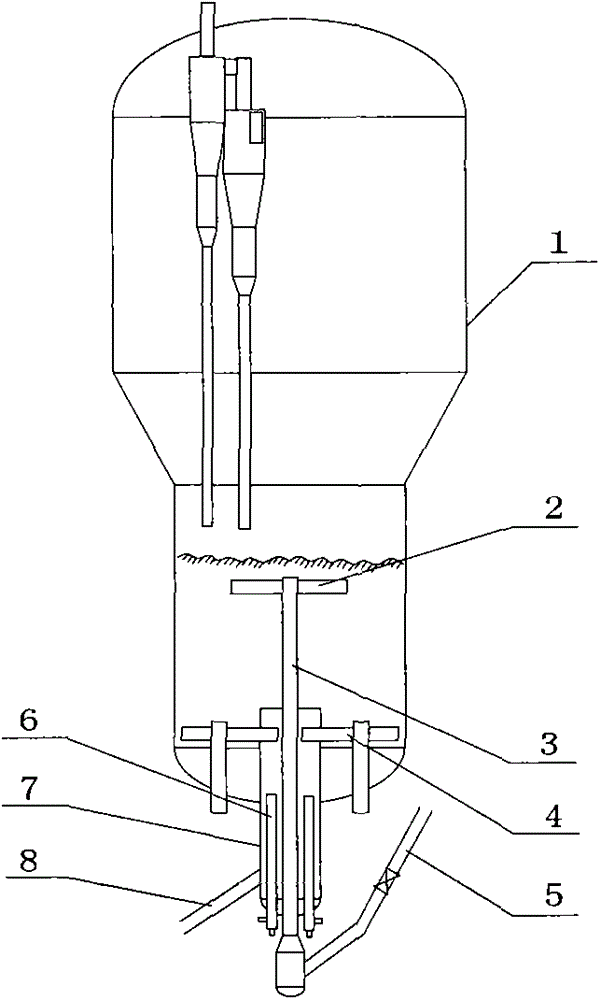

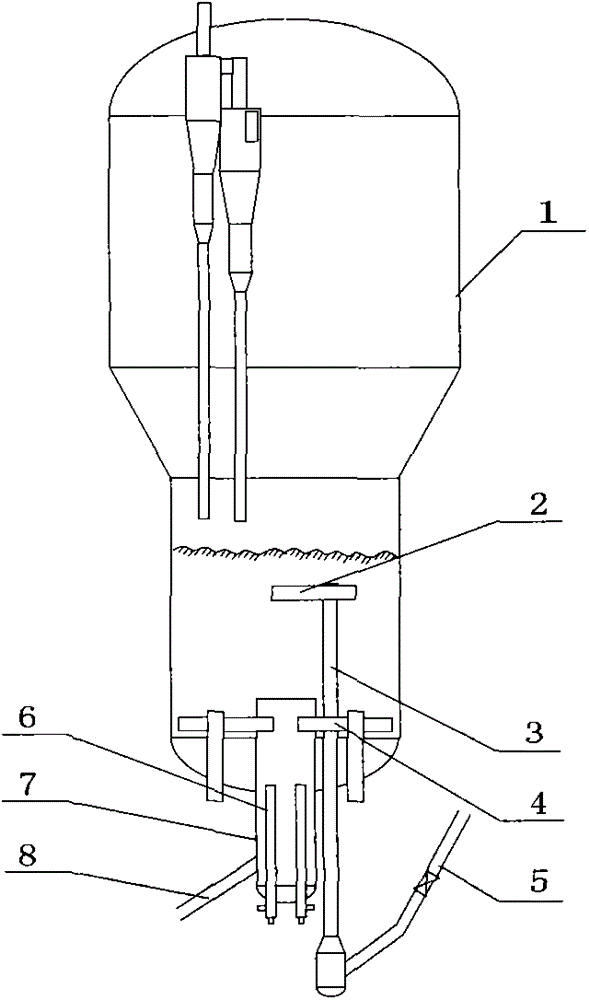

[0020] See figure 1 , figure 2 , the lower part of the regenerator 1 has the main air distribution pipe 4, and the central lead-out pipe 7 extends from the bottom center of the regenerator 1 from bottom to top, and its lower part is connected with the regenerant delivery pipe 8, and the heat-taking pipe 6 extends into the central lead-out pipe 7 from bottom to top . The spent agent riser 3 extends into the regenerator 1 through the central outlet pipe 7 from bottom to top, its upper end is connected with the spent agent distributor 2 , and its lower end is connected with the spent agent feed pipe 5 . figure 2 The spent agent riser 3 directly extends into the regenerator 1.

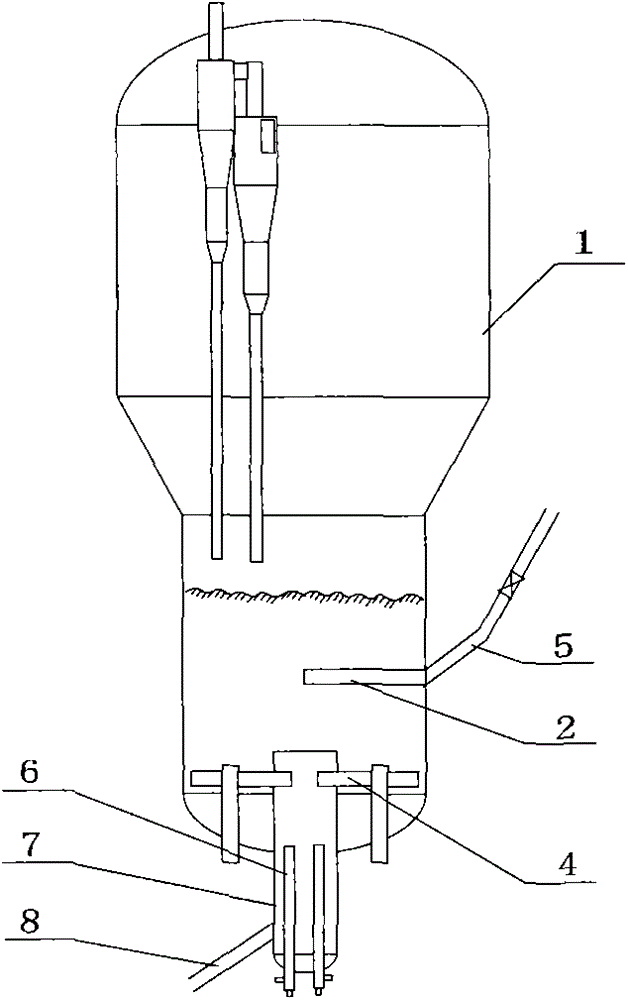

[0021] See image 3 , the lower part of the regenerator 1 has the main air distribution pipe 4, and the central lead-out pipe 7 extends from the bottom center of the regenerator 1 from bottom to top, and its lower part is connected with the regenerant delivery pipe 8, and the heat-taking pipe 6 extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com