Program-controlled pig bionic digestion system and method using program-controlled pig bionic digestion system to quickly determining digestible energy value of pig feed

A digestive system, program-controlled technology, applied in the agricultural field, can solve problems such as rupture and inability to truly simulate large intestine digestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

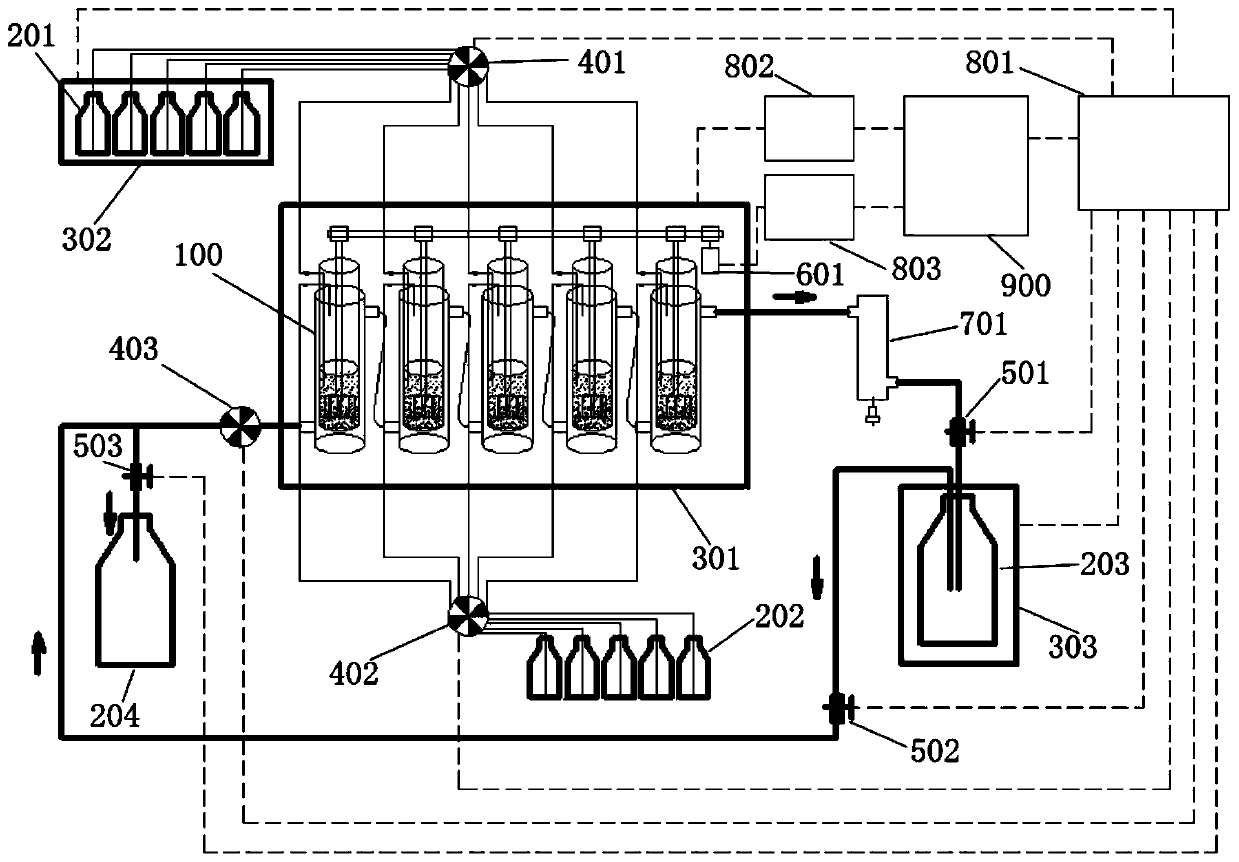

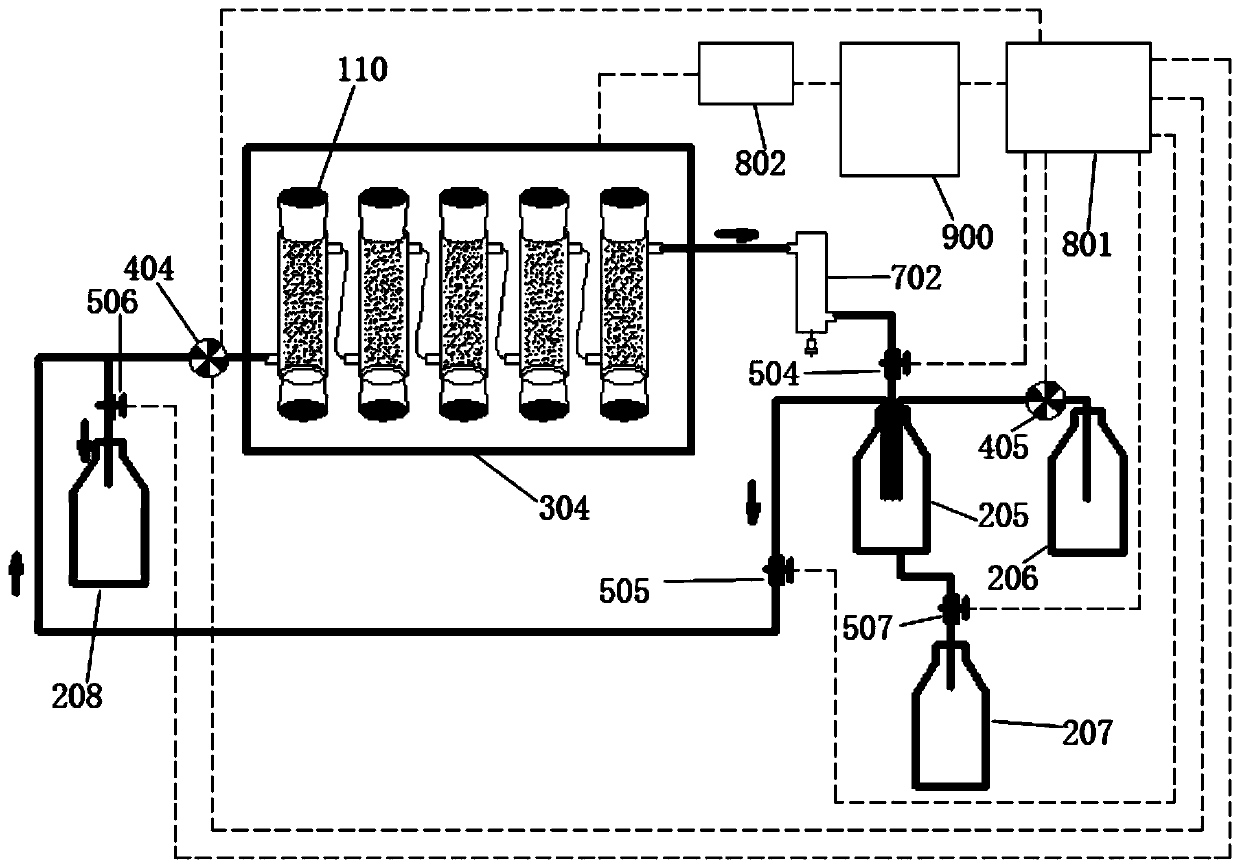

[0078] Such as Figure 1-2 Shown is a program-controlled pig bionic digestion system provided by the present invention, which is composed of a reaction unit and a cleaning unit;

[0079] Wherein, the reaction unit includes a simulated digester 100, a supporting stirring device 700, a digestion liquid storage bottle 201, a buffer storage bottle 202, a deionized water reagent bottle 203, and a waste liquid collection bottle 204;

[0080] There is at least one simulated digester 100, and the number of the digestive solution storage bottle 201 and the buffer solution storage bottle 202 corresponds to the number of the simulated digester 100;

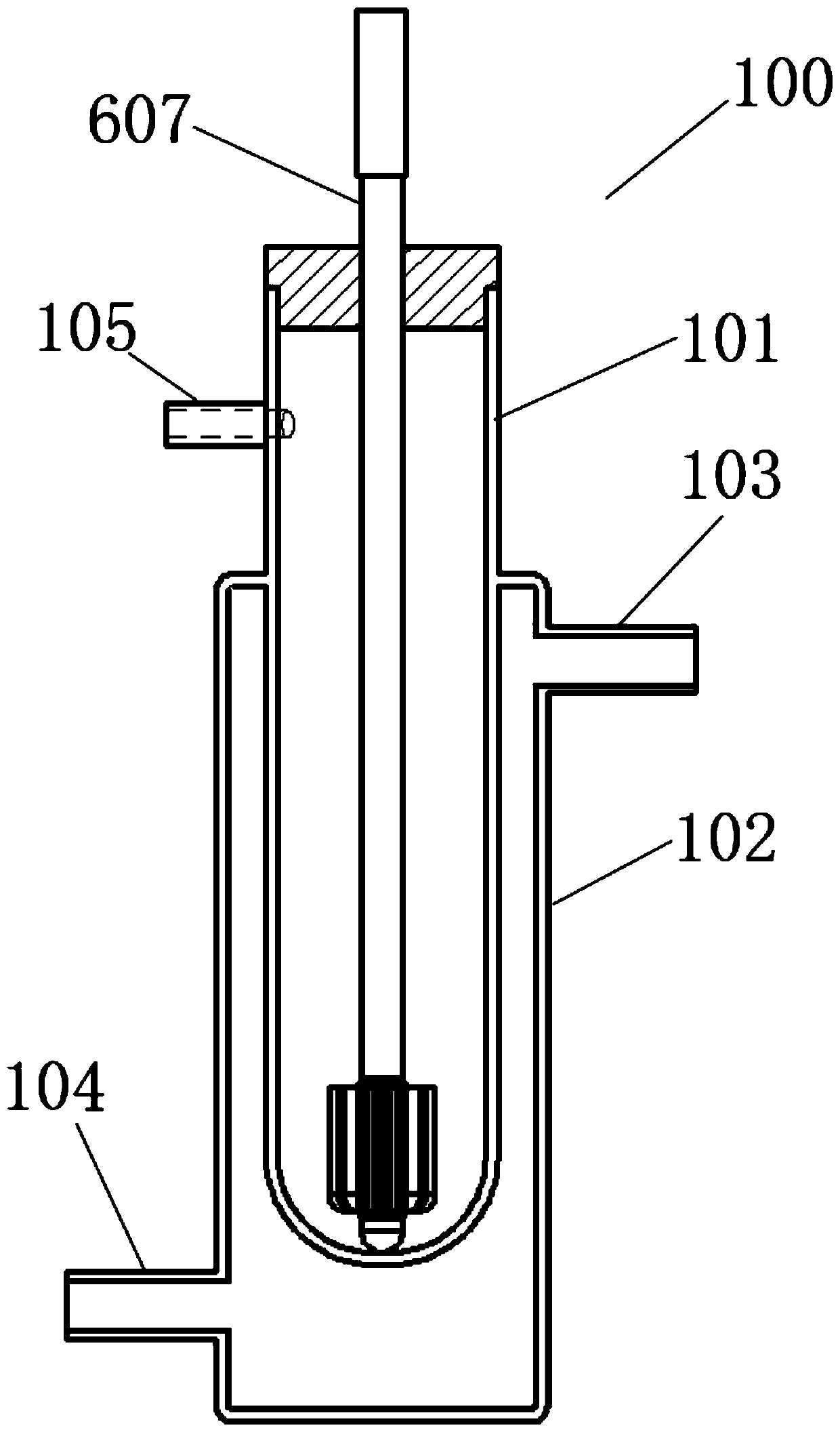

[0081] Such as Figure 3-4 As shown, the simulated digester 100 is made up of two layers of glass tubes inside and outside. The inner glass tube 101 opens upwards, and the outer glass tube 102 is connected to the upper part of the inner glass tube 101 by shrinking and connecting the inner glass tube 101. The opening of the tube 101 is higher than t...

Embodiment 2

[0106] Determination of the digestible energy value of corn and barley by pig bionic digestion method

[0107] 1. Pretreatment of feed ingredients to be tested

[0108] Sampling according to GB / T 14699.1, using 3 corns (total energy 4444-4475kcal / kg DM, crude protein 7.69%~7.90%, crude fat 2.99%~3.52%, crude ash content 1.09%~1.17%), 2 barley (Total energy 4408~4441kcal / kg DM, crude protein 8.26%~10.01%, crude fat 1.74%~1.90%, crude ash content 1.47%~1.77%) were taken as representative feed samples. Divide the collected feed samples into quarters to about 200g, crush them with a universal pulverizer, pass through a 60-mesh standard sieve, seal them in a sample bag and store at -20°C for later use.

[0109] 2. The bionic digestion process of pigs

[0110] 2.1 Preparation of buffer and simulated digestion:

[0111] Gastric buffer (500mL): Weigh 2.59g of NaCl, 0.25g of KCl, and 6g of anhydrous sodium dihydrogen phosphate. Dissolve in 450mL deionized water, adjust the pH to 2.0 with 2mol...

Embodiment 3

[0181] Determination of digestible energy value of wheat, early rice, sorghum and broken rice by pig bionic digestion method

[0182] Reference Figure 1-6 The in vitro bionic digestion method for rapid determination of digestible energy value of pig feed in this embodiment has the following differences from embodiment 1-6:

[0183] 1 Pretreatment of feed ingredients

[0184] Sampling according to GB / T 14699.1 2 wheat (GE 4460~4493kcal / kg DM, CP 14.25%~15.33%, EE 1.44%~1.68%, Ash 1.41%~1.53%), 1 early rice and 1 broken rice ( GE 4306~4365kcal / kg DM, CP 7.40%~7.66%, EE 0.50%~1.83%, Ash 0.24%~3.34%), 1 sorghum (GE 4476kcal / kg DM, CP 8.46%, EE 3.02%, Ash 1.28 %) and other commonly used pig feed ingredients as representative feed samples. After being crushed by a universal pulverizer and passing through a 60-mesh standard sieve, they were put into feed sample bags and sealed at -20°C for later use.

[0185] 2 Pig's bionic digestion process

[0186] Same as Example 2

[0187] 3 Bionic dig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mwco | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com