Regenerated catalyst thermoregulation device for catalytic cracking equipment

A technology for regenerating catalysts and temperature-adjusting equipment, which is used in catalytic cracking, cracking, petroleum industry, etc., can solve the problems that the ratio of catalyst to oil cannot be flexibly increased according to actual requirements, and the structure is complex, and achieves consistent activity, high reaction activity, and realization agent. The effect of oil ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

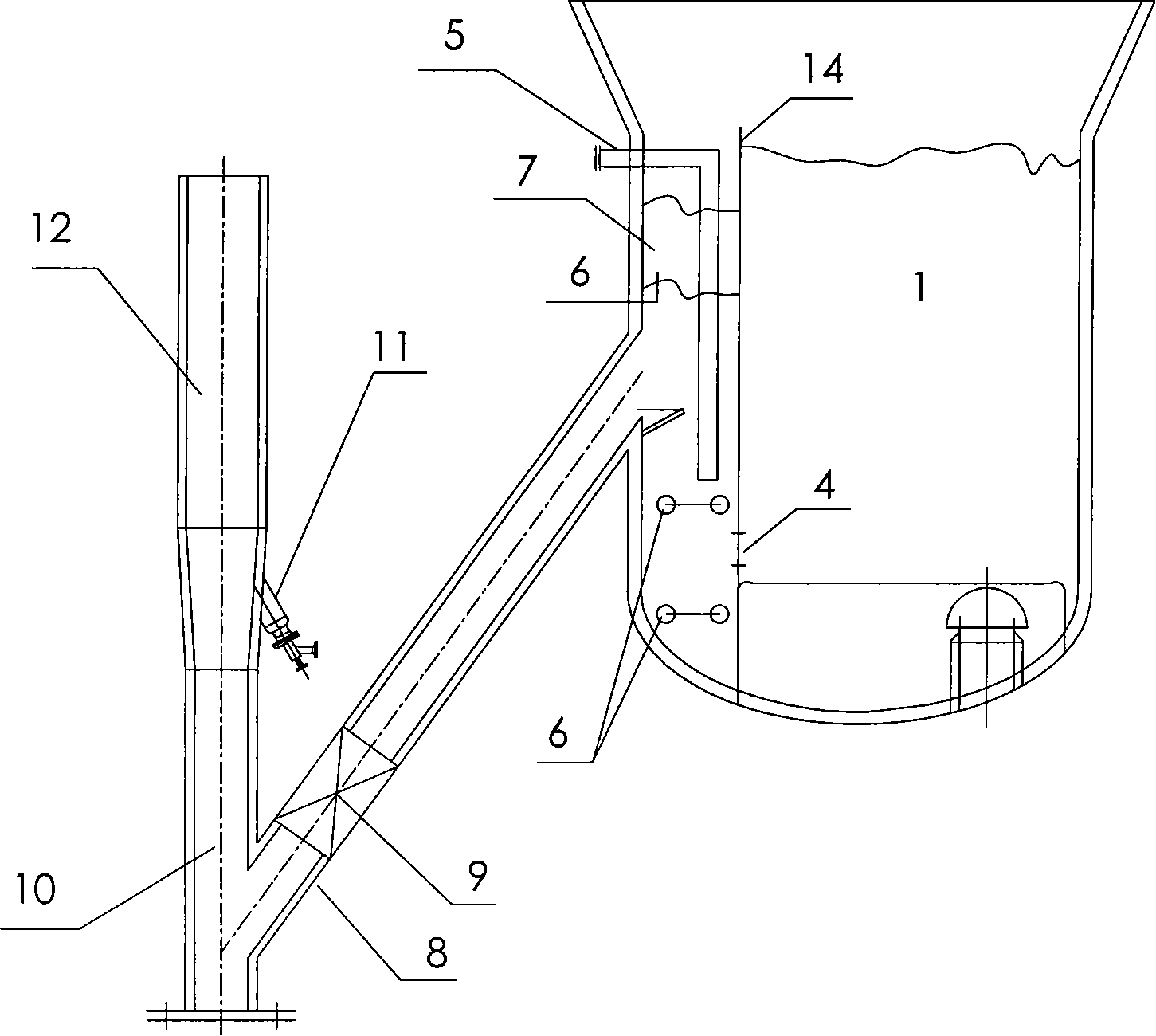

[0014] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only drawn to illustrate the basic content of the present invention, and do not limit the scope of the present invention.

[0015] As shown in the figure, the catalytic cracking unit regenerated catalyst temperature-regulating equipment of the present invention includes a regenerator dense-phase bed 1 and a riser reactor reaction section 12, and a partition 14 is arranged in the regenerator dense-phase bed 1, and the regenerator dense-phase The bed 1 is divided into two areas, one area is the regenerated coke area, and the other area is the catalyst desuperheater area 7, and the lower part of the partition 14 is provided with the desuperheater catalyst inlet 4. A heat-taking pipe 5 is provided in the catalyst desuperheater area 7, and a fluidized ring 6 is arranged in sections along the vertical height of the cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com