A double-layer aluminum electrolytic cell cover plate with side suction and enhanced heat preservation

An aluminum electrolytic cell and aluminum plate technology, which is applied in the field of electrolytic cell cover plate, can solve the problems of uneven distribution of temperature field in the electrolytic cell, inability to achieve uniform and rapid flue gas, and inability to completely seal the cell cover plate, so as to achieve uniform gas collection Fast side suction, uniform and fast absorption of smoke, enhanced service life and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

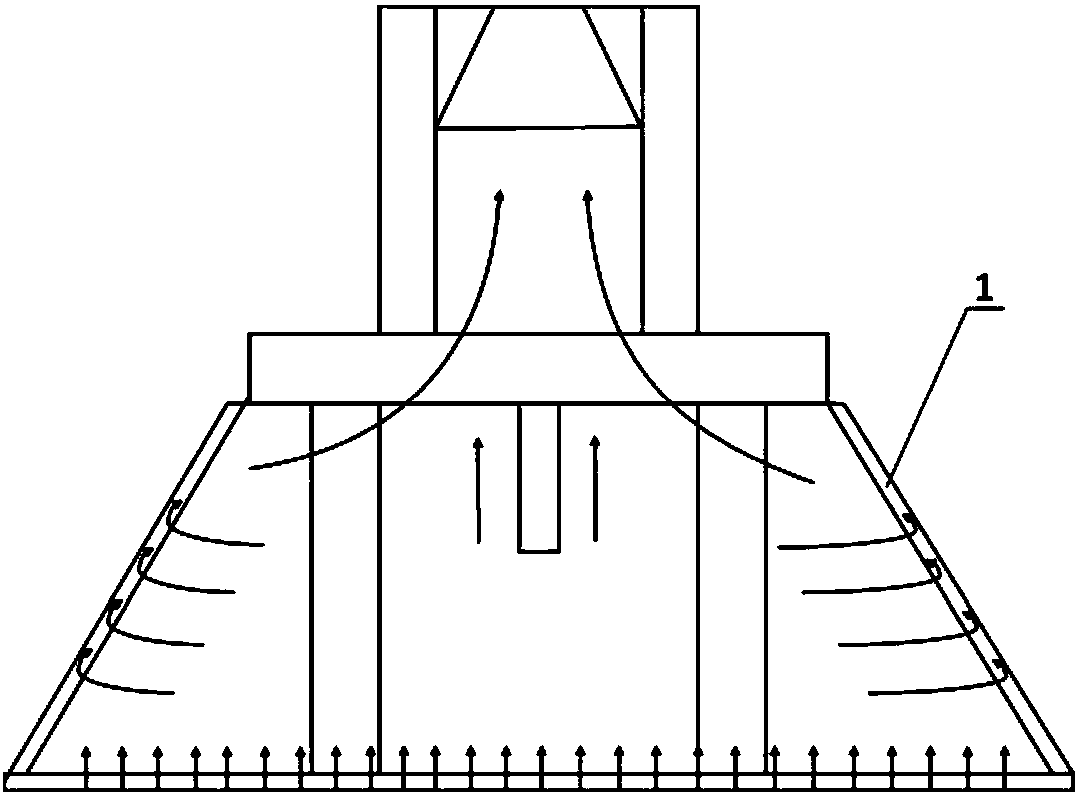

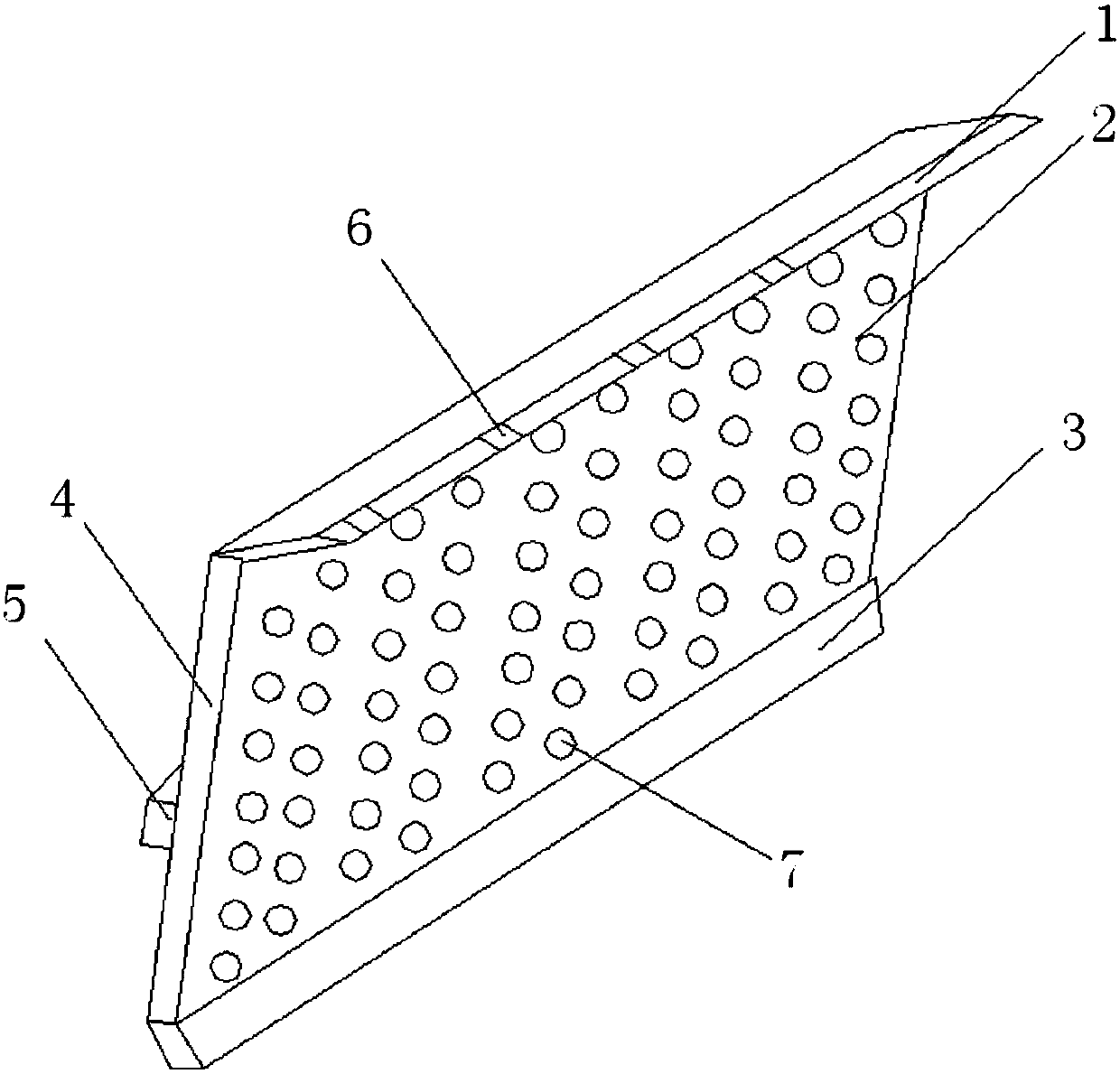

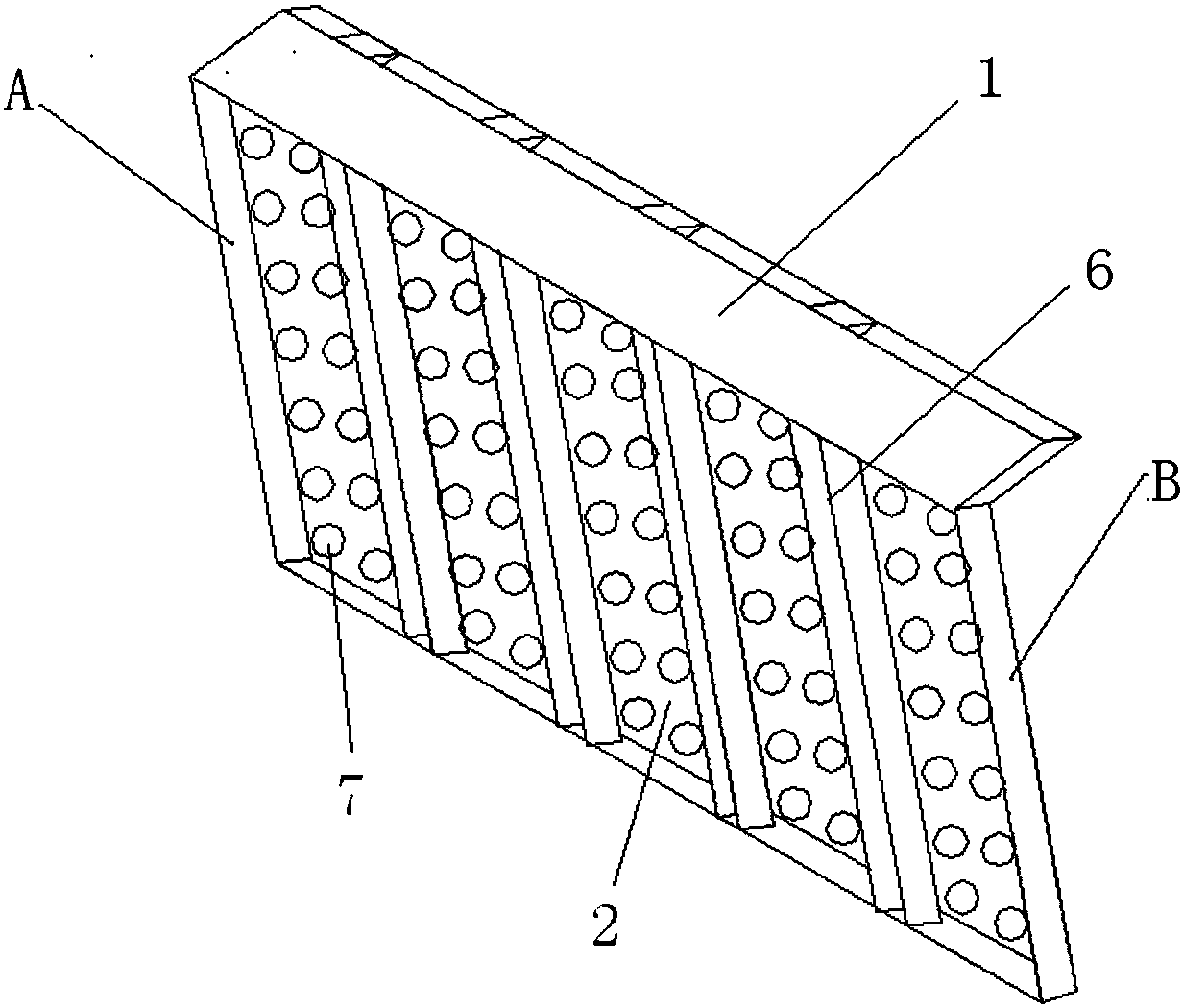

[0025] Such as figure 2 , image 3 with Figure 4 As shown, the present invention includes an upper hollow frame 1, an inner aluminum plate with ventilation holes 2, a lower solid frame 3, a hollow interlayer 4 of two layers of aluminum plates, an outer groove cover plate 5 and an inner support frame 6, and an inner aluminum plate with ventilation holes The inner layer aluminum plate of 2 is directly drilled with a vent hole 7, the diameter of the vent hole 7 is between 1cm-5cm, and the coverage rate of the vent hole 7 is 50%-75%, which can be processed into an aluminum plate with an inner layer with vent holes 2 . Weld the upper hollow frame 1 and the inner aluminum plate 2 with vents together, weld several steel bars between the upper hollow frame 1 and the inner aluminum plate 2 with vents as the internal support frame 6, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com