Large space frame type gas collection lower flue structure

A frame-type, large-space technology, applied in the field of flue structure, can solve the problems of excessive fluoride discharge in the skylight of the electrolysis workshop, inability to protect the upper structure of the tank, and unbalanced gas collection effect of the flue system, etc. The effect of the upper smoke problem, the equal suction air collection efficiency, and the reduction of contact strength and deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

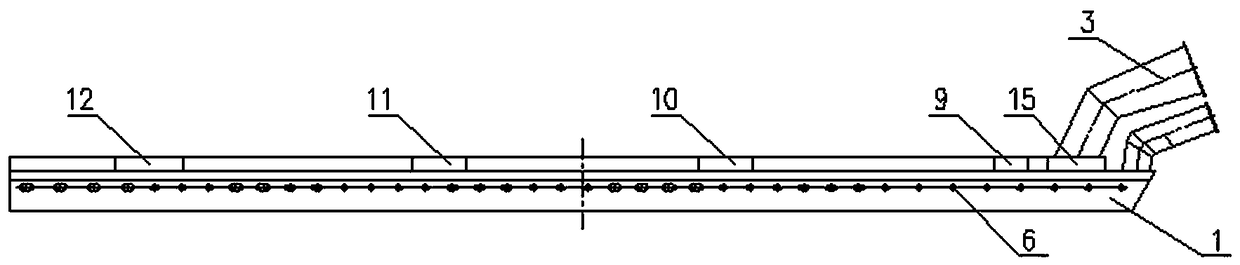

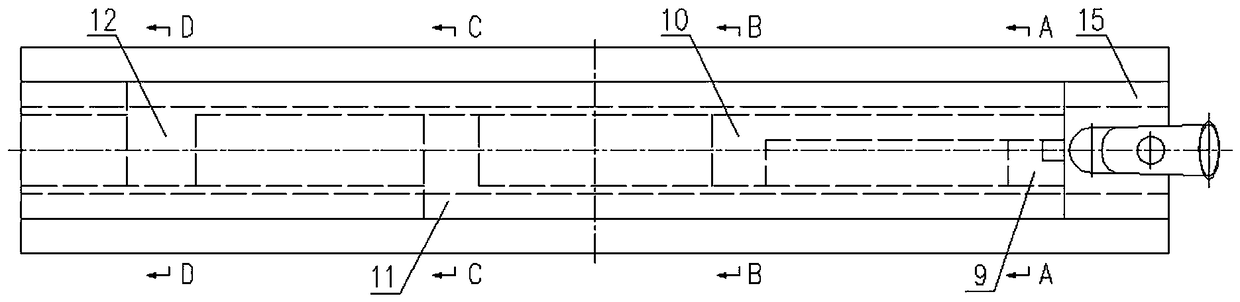

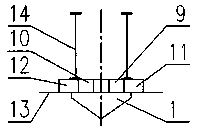

[0021] As shown in the figure, the large-space frame-type gas-gathering lower flue structure divides the gas-gathering lower flue 1 into 2-10 sections, and each section of the sub-flue is equipped with an independent branch pipe for separate gas collection, which converges in the collective smoke chamber 15, The summed smoke cavity 15 is connected with the main smoke exhaust pipe 3, the gas-collecting lower flue 1 is set at the bottom of the horizontal cover plate 13, each branch smoke pipe is welded above the horizontal cover plate 13, and the bottom of the girder 14 is welded to the bottom of the branch smoke pipe. top.

[0022] The gas-collecting lower flue 1 is divided into four sections, and the branch smoke pipes are the first smoke pipe 12, the second smoke pipe 11, the third smoke pipe 10 and the fourth smoke pipe 9, and each smoke pipe passes through The smoke pipe is connected to the collecting smoke chamber 15 .

[0023] Four cigarette pipes form a frame structure....

Embodiment 2

[0028] The gas-collecting lower flue 1 is divided into five sections, and the fifth section of the sub-flue opens at the bottom of the collection smoke chamber 15 . Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com