Aluminum electrolytic cell closed gas collecting device

A technology of aluminum electrolytic cells and gas collection devices, which is applied in the field of aluminum electrolytic cells, can solve the problems of aluminum electrolytic cells that are not environmentally friendly and the efficiency of waste gas collection is not high, and achieve the effects of improving energy utilization, significant energy saving effects, and huge energy saving potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

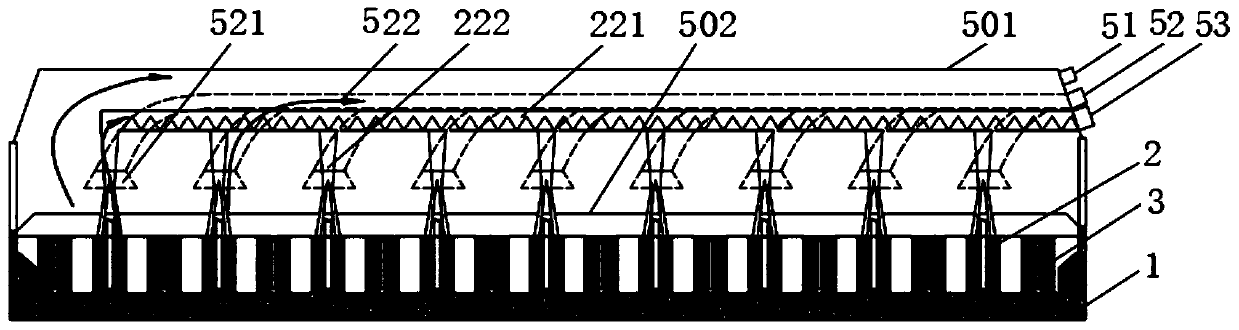

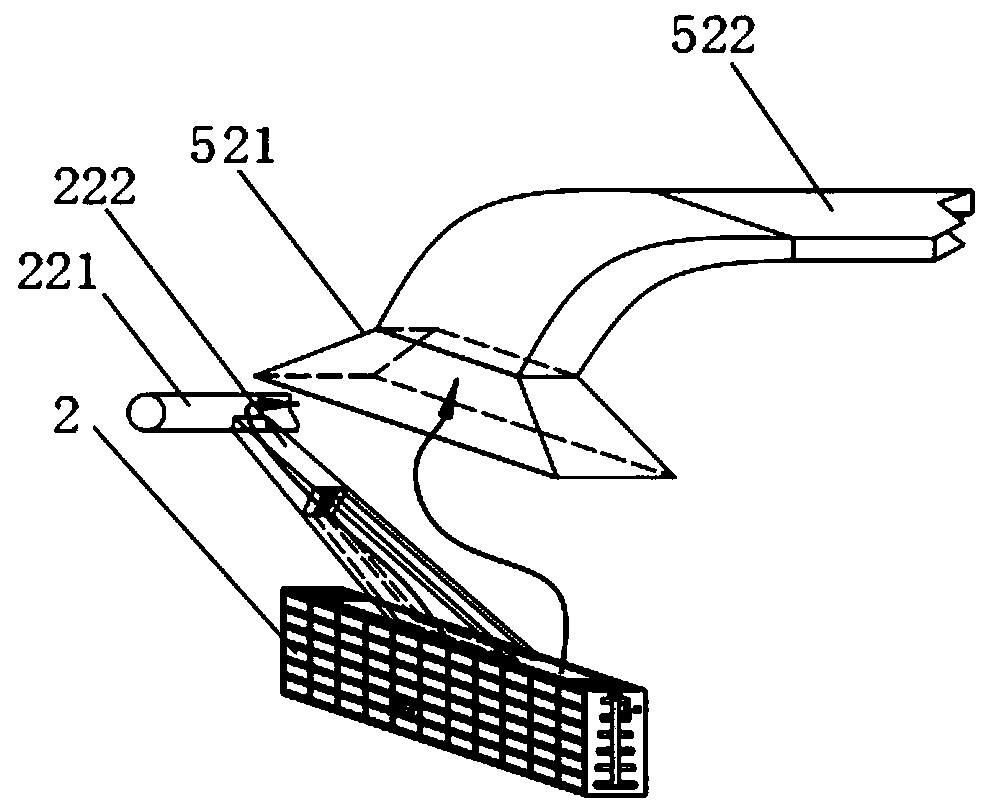

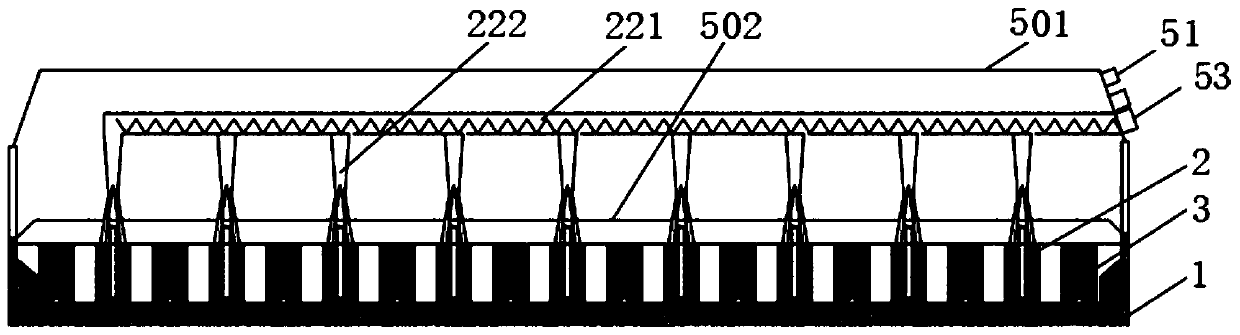

[0032] see figure 1 , the multi-chamber aluminum electrolytic cell shown in the figure is a specific implementation of the airtight gas collection device for the aluminum electrolytic cell of the present invention. In the aluminum electrolytic cell in the figure, anodes 2 and cathodes 3 are alternately arranged in the horizontal direction of the cell body 1, and the electrolytic cell The number of cathodes 3 inside is 10 groups, and the number of anodes 2 is 9 groups. Each group of anodes 2 and cathodes 3 adopts a plate-type electrode structure with the same electrolysis area size. Adjacent anodes 2 and cathodes 3 are arranged vertically and Parallel electrolytic chambers are formed with the same height, and at least two such electrolytic chambers are formed along the horizontal direction inside the cell body 1 of the entire electrolytic cell.

[0033] In this embodiment, the cathode 3 is fixed on the bottom of the tank body 1 by prefabricated cathode carbon block, and the ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com