Gas gathering system of divisional gas-gathering type aluminum electrolytic bath

An aluminum electrolytic cell and electrolytic cell technology, which is applied in the field of gas collection system, can solve the problems of the V-shaped structure device being close to the fire hole, the limitation of gas collection efficiency, and the complicated upper structure, so as to improve the uniformity of negative pressure distribution in the tank and reduce the Weight, effect of improving tank life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

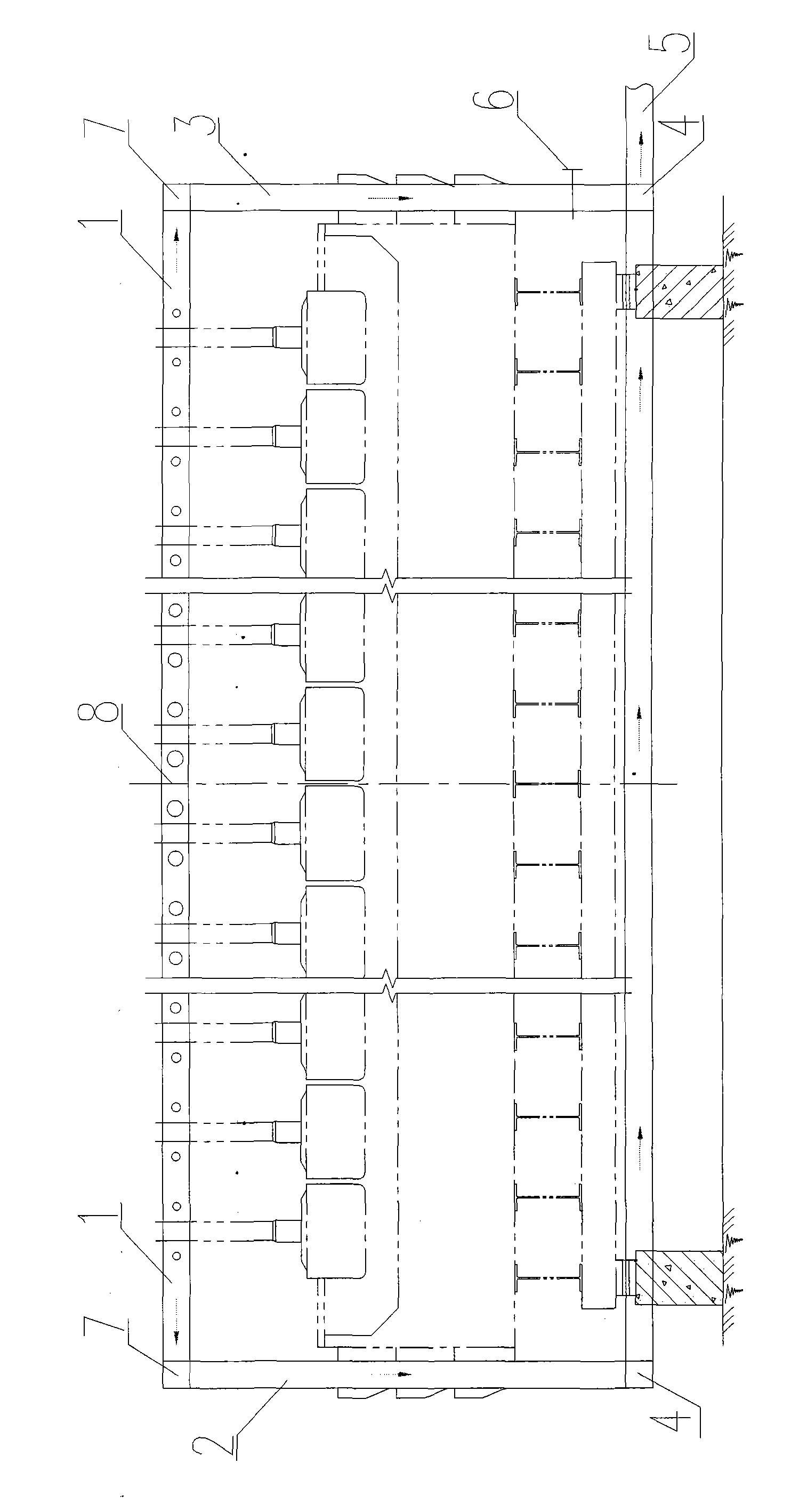

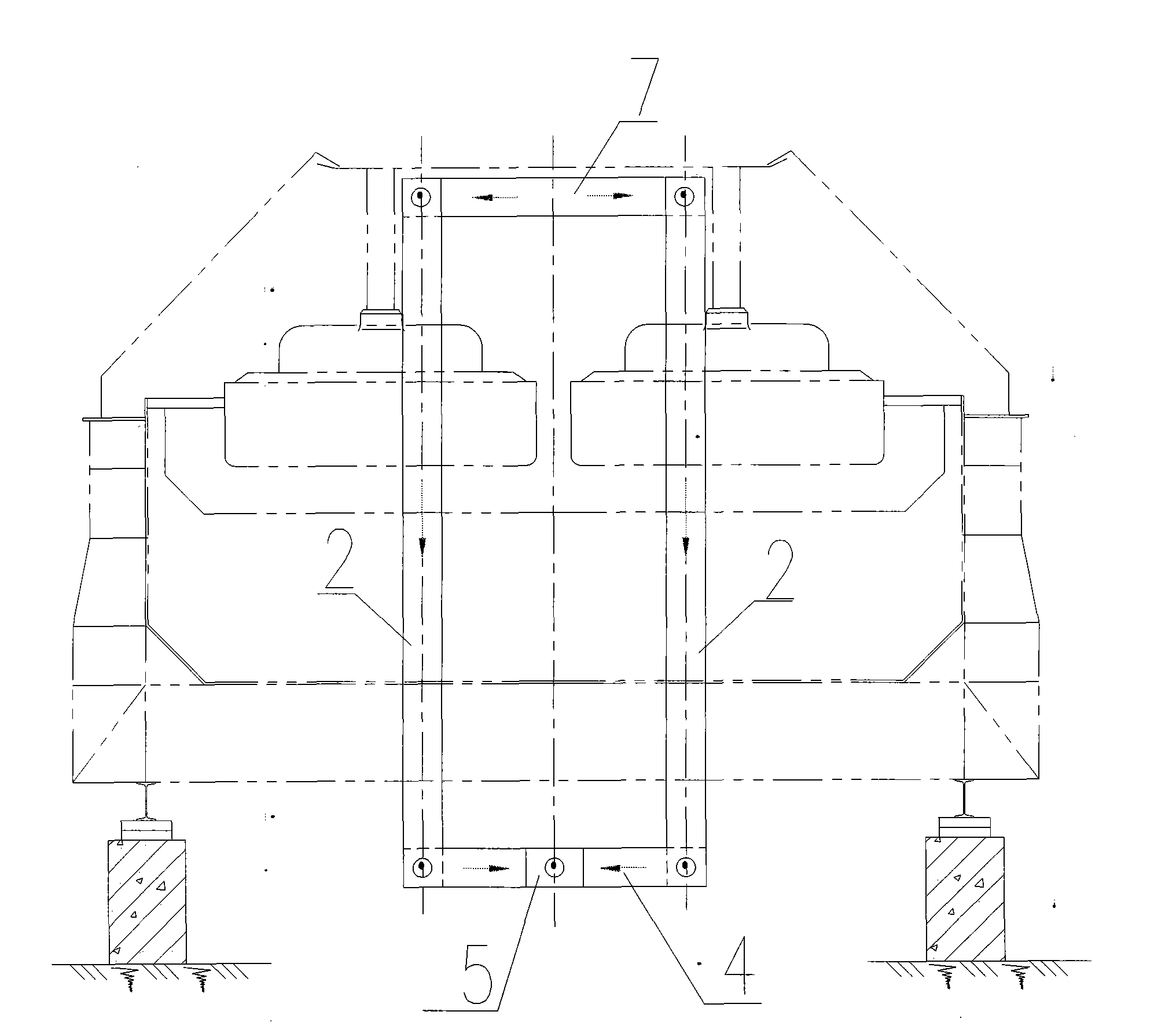

[0030] Such as figure 1 , figure 2 , image 3 As shown, it is the structural form of the gas collection system ① of the partitioned gas collection type aluminum electrolytic cell of the present invention. The gas collection system includes a horizontal flue 1 in the tank, a partition 8, a vertical flue 2 on the left, and a vertical flue 3 on the right. , Bottom confluence flue 4, upper confluence flue 7, total flue 5 and regulating valve 6. The horizontal cover plates on the upper part of the horizontal flue in the groove are combined together, the number is 2, and the height of the horizontal flue in the groove is 300mm. The baffle is perpendicular to the length direction of the horizontal flue and divides its length equally. In this way, the horizontal flue and the baffle divide the horizontal gas-gathering area into 6 areas I, II, III, IV, V, and VI. The upper converging flue 7 is arranged at both ends of the horizontal flue in the tank and communicates with both ends o...

Embodiment 2

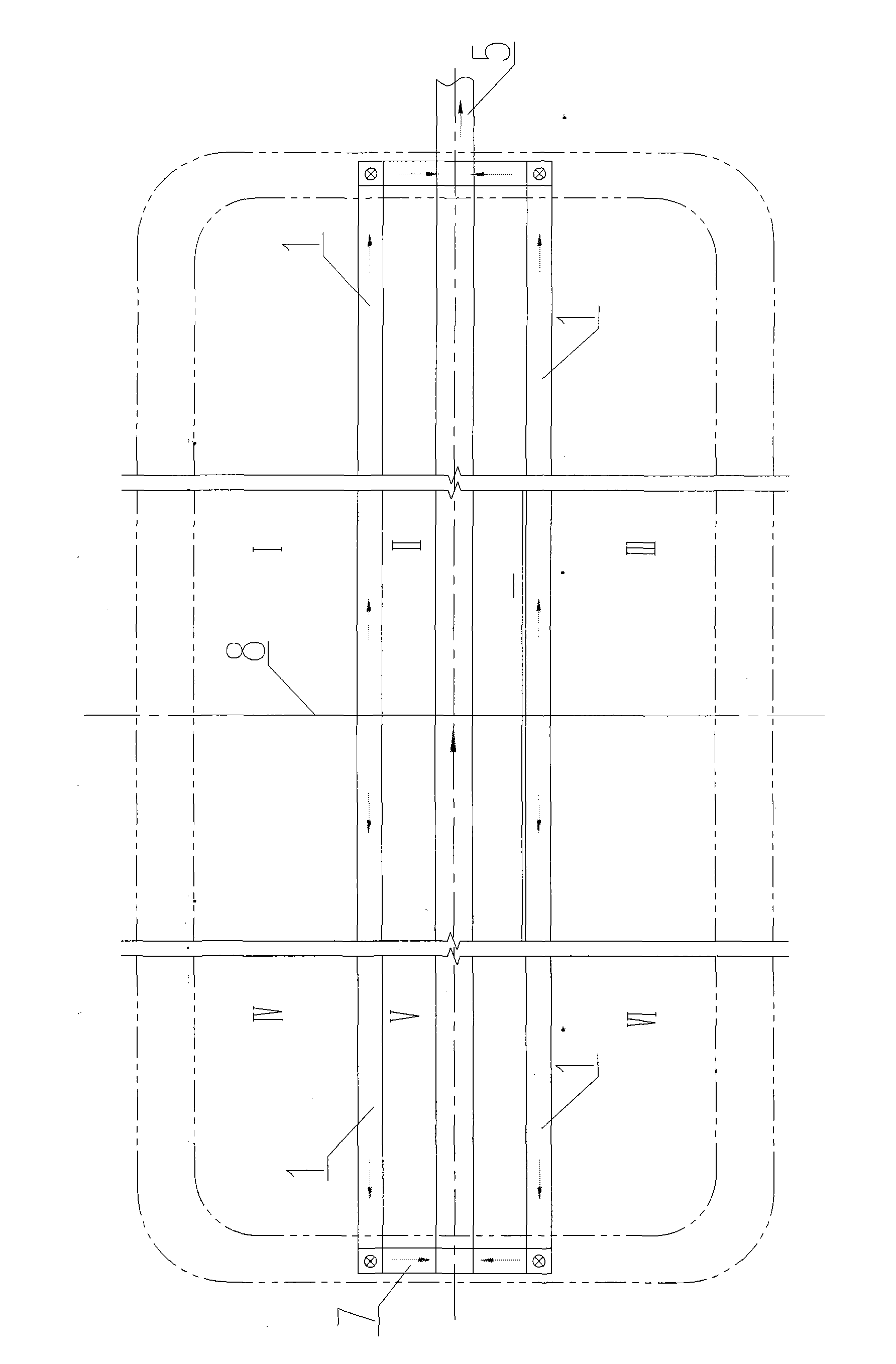

[0033] Such as Figure 4 As shown, it is the structural form of the gas collection system of the partitioned gas collection type aluminum electrolytic cell of the present invention ②, the gas collection system includes a horizontal flue 1 in the tank, a partition 8, a vertical flue 2 on the left, and a vertical flue 3 on the right , the bottom confluence flue 4, the upper confluence flue 7, the total flue 5 and the regulating valve 6. The horizontal flue in the tank is independent, the number is 5, and the height of the horizontal flue in the tank is 400mm. The baffle is perpendicular to the length direction of the horizontal flue and equally divides its length. In this way, the horizontal flue and the baffle divide the horizontal gas-gathering area into multiple areas, and the number of areas is 12. The upper converging flue 7 is arranged at both ends of the horizontal flue 1 in the tank, and communicates with both ends of the horizontal flue 1 in the tank. The left vertica...

Embodiment 3

[0036] Such as Figure 5 As shown, it is the structural form of the gas collection system of the partitioned gas collection type aluminum electrolytic cell of the present invention ③, the gas collection system includes a horizontal flue 1 in the tank, a partition 8, a vertical flue 2 on the left, and a vertical flue 3 on the right , Bottom confluence flue 4, upper confluence flue 7, total flue 5. The horizontal flue 1 in the groove is combined with the horizontal cover plate on the upper part of the groove, the number is 3, and the height of the horizontal flue 1 in the groove is 100mm. The baffle is perpendicular to the length direction of the horizontal flue and divides its length equally. In this way, the horizontal flue and the baffle divide the horizontal gas-gathering area into multiple areas, and the number of areas is 8. The upper converging flue 7 is arranged at both ends of the horizontal flue in the tank and communicates with both ends of the horizontal flue in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com