A gas collection device for liquid raw material feeding and mixing system

A technology of gas collection device and mixing system, which is applied in the direction of mixer, transportation and packaging, dissolution, etc., can solve the problems of lack of consideration and standardization design, and achieve the effect of improving gas collection efficiency, standardization and stable collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

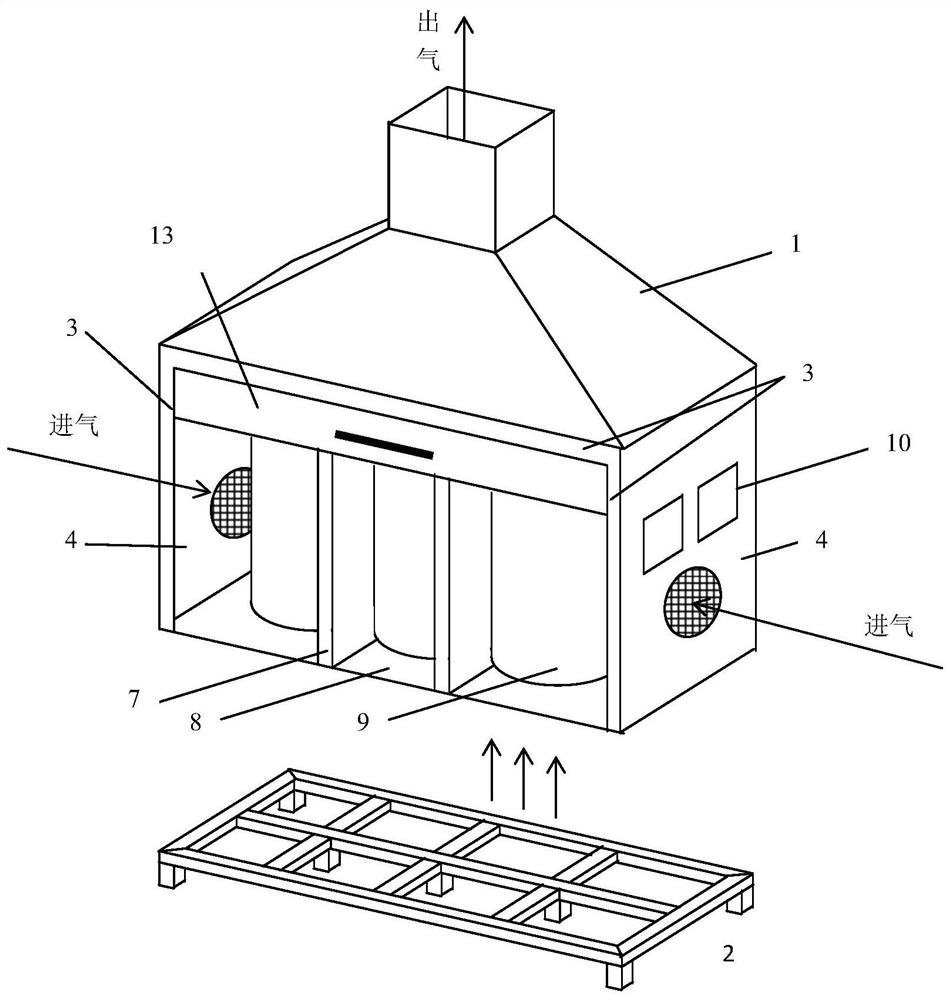

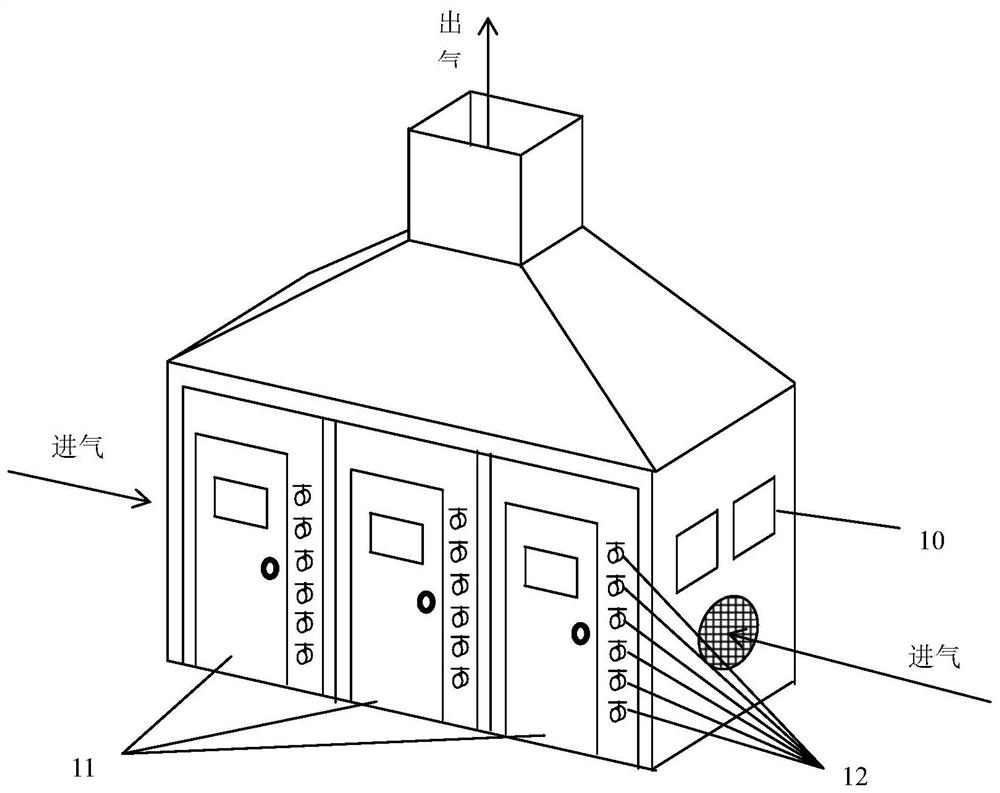

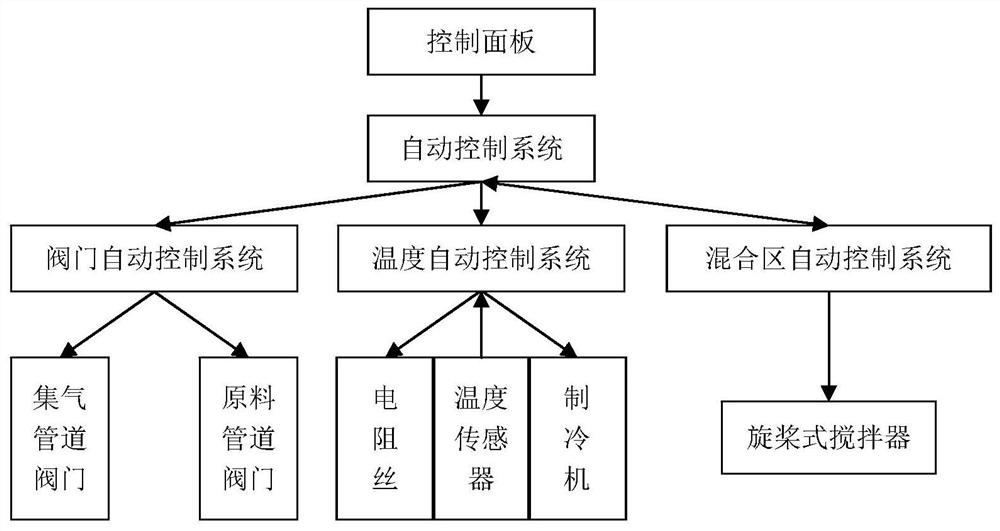

[0030] Such as figure 1 , figure 2 , image 3 Shown is a gas collection device for liquid raw material feeding and mixing systems, including a gas collection box with a raw material barrel placed inside, a top suction gas collection hood 1 arranged at the top opening of the gas collection box, and an automatic control system , the left and right sides of the gas collection box are provided with air inlets, and the back is fixed and sealed by surfacing welding with a number of raw material pipe joints 12 for connecting the raw material barrel 9 and the raw material delivery pipeline. The automatic control system includes:

[0031] The valve automatic control system is used to adjust the opening of the gas-gathering pipeline valve according to the opening of the raw material pipeline valve;

[0032] An automatic temperature control system, used to control the temperature of the air entering the air inlet according to the temperature in the gas collection box;

[0033] The ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com