Automatic safety cone deploying and retracting system and vehicle-mounted system thereof

An automatic retractable and dynamic system technology, applied to roads, road signs, traffic signals, etc., can solve problems such as low work efficiency, dangerous work environment, and heavy workload, and achieve simple structure, high degree of automation, and stable work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

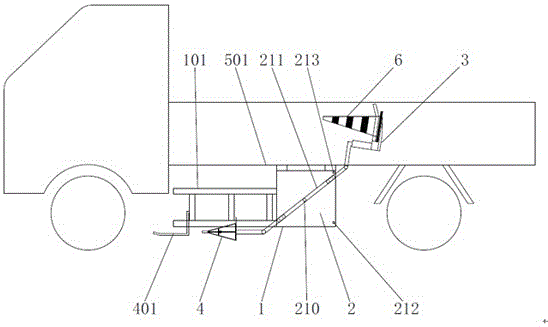

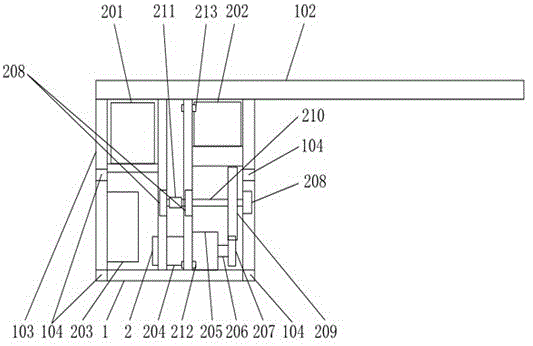

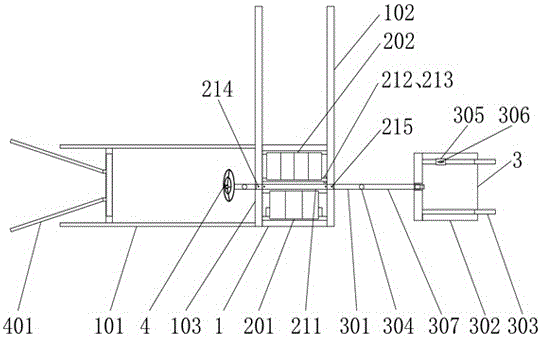

[0047] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a safety cone automatic retracting system, comprising a rack carrying device 1, a swing arm type automatic control power system 2, a cone deployment device 3, and a cone collection device 4; the swing arm type automatic control power system 2 Set in the rack bearing device 1, the motor output shaft of the swing arm type automatic control power system 2 is connected to a swing arm sleeve rod 211, and one end of the swing arm sleeve rod 211 is provided with a cone deployment device 3, the The other end of the swing arm sleeve rod 211 is provided with a cone collection device 4; the swing arm type automatic control power system 2 includes a battery 202, a transmission system and a power control system, and the transmission system relies on the power control system to realize the forward and reverse of the transmission system. switch.

[0048] In order to play a better guiding role, it also includes a cone g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com