Electrolytic bath air gathering method

An electrolytic cell and gas collection technology, which is applied in the gas collection field of electrolytic cell flue gas, can solve the problems of large pressure loss, poor gas collection effect at the tail, and low gas collection efficiency, and achieve the effect of improving gas collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

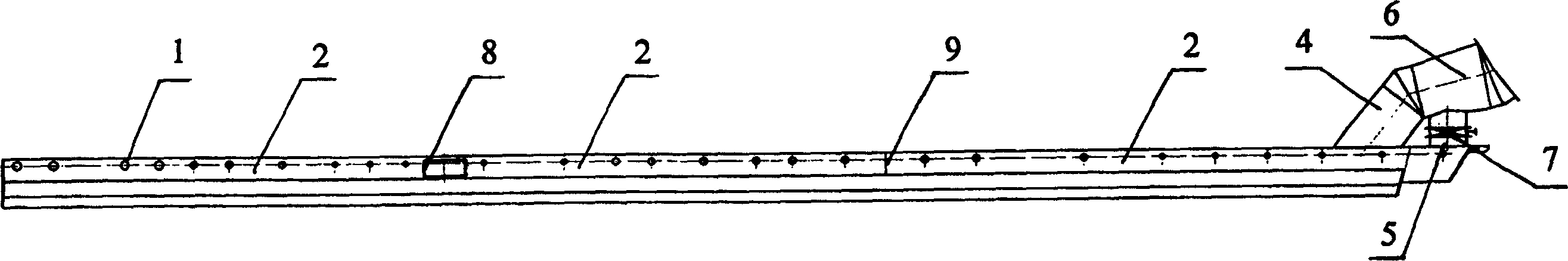

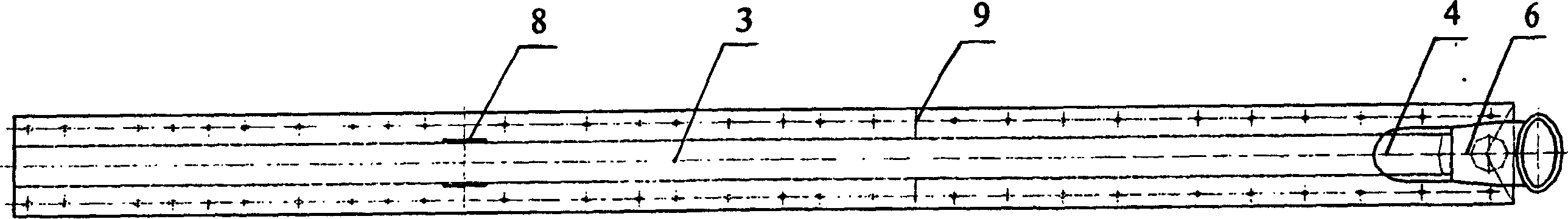

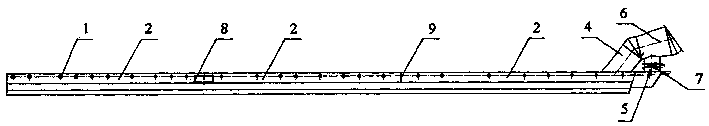

[0009] According to the smoke exhaust volume of a single tank and the smoke exhaust volume of each section of gas collection branch pipeline shall not exceed 4000m under standard conditions 3 / h, to determine the segment number of segmented gas collection; according to the principle of negative pressure and resistance balance, as well as the exhaust volume and flue gas flow rate of the branch pipe, determine the size of each gas collection branch pipeline. Taking a certain 300kA electrolytic cell as an example, it can be divided into three stages of gas collection. The gas collection branch pipe 2 is distributed along the longitudinal centerline of the electrolytic cell. Each section of the gas collection branch pipe 2 is welded by steel plates or steel pipes. are independent of each other; the first two sections of flue gas enter the gas collecting branch pipe 2 through the air inlet 1 or the gas collecting hood on the gas collecting branch pipe 2, and a communication hole 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com