Construction method for miniature steel pipe concrete pile to penetrate through roadbed layer for reinforcing soft foundation construction

A technology for steel pipe concrete piles and weak foundations, which is applied in foundation structure engineering, sheet pile walls, earthwork drilling and mining, etc., can solve the problems that the construction cannot be carried out and cannot meet the requirements of foundation strength, etc. It is easy to master, and the construction equipment is small and convenient. The effect of flexibility and flexible pile layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

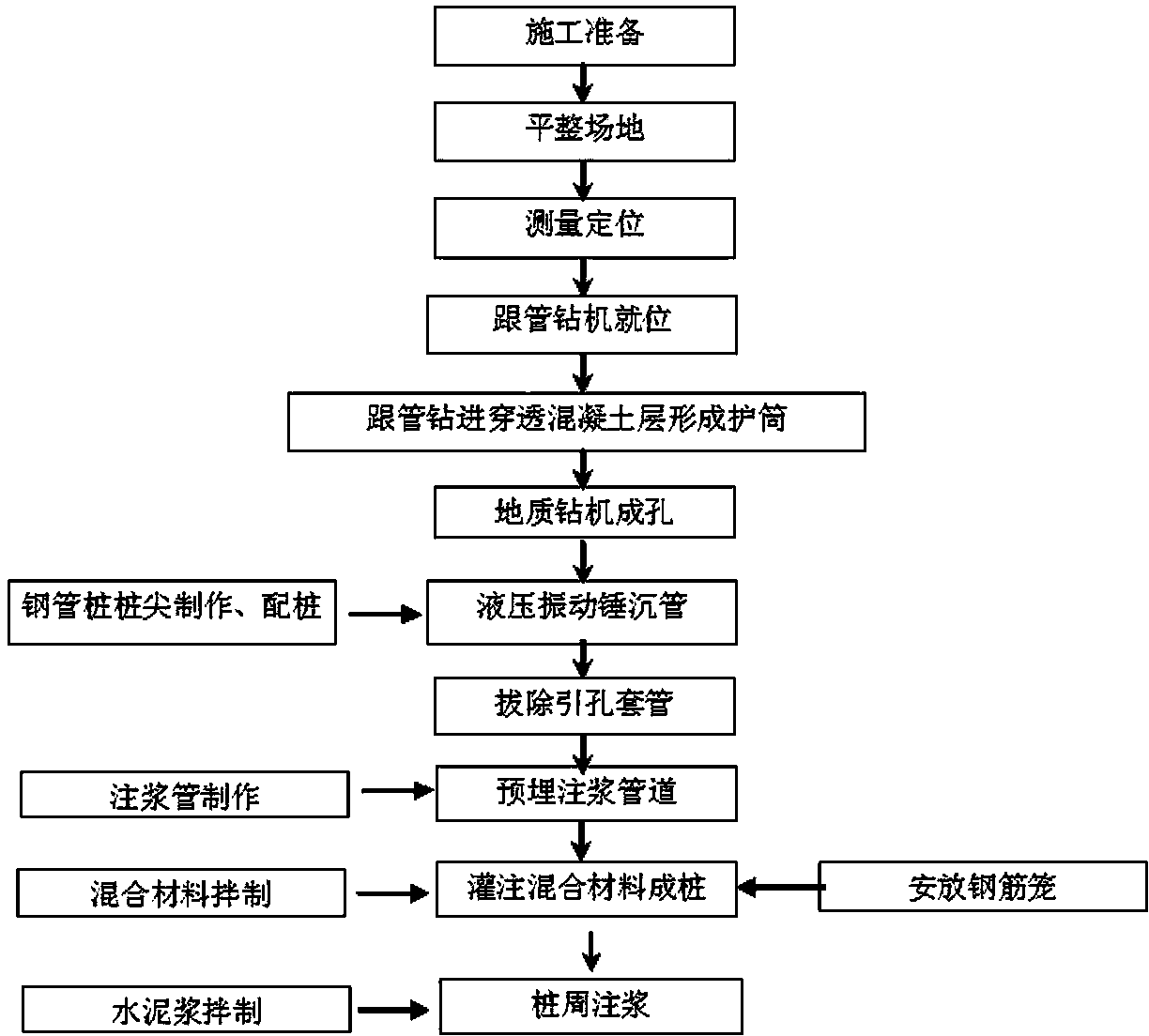

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific examples.

[0035]After the abutment and subgrade transition section of a super-large bridge were laid and entered the joint commissioning and joint test, it was found through settlement observation that the post-construction settlement could not meet the design requirements, and the abutment and subgrade transition section needed to be reinforced. Because there is a certain thickness of concrete near the abutment foundation, and the construction site is narrow, the prestressed pipe pile reinforcement measures cannot be implemented according to the design. It is decided to use micro-concrete-filled steel pipe piles for reinforcement treatment. 16 rows of micro-concrete-filled steel-filled piles are arranged horizontally along the subgrade surface, with a horizontal spacing of 0.7m, and 2 rows of micro-filled steel-filled concrete piles are arranged vertically, with a longitudinal spacing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com