Ultra-wide steel box girder component of a bridge and a water splicing method thereof

A steel box girder and component technology, applied in the field of steel structure bridges, can solve the problems of difficult transportation, inconvenient construction, trouble, etc., and achieve the effects of ensuring construction quality, saving costs, and accelerating construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

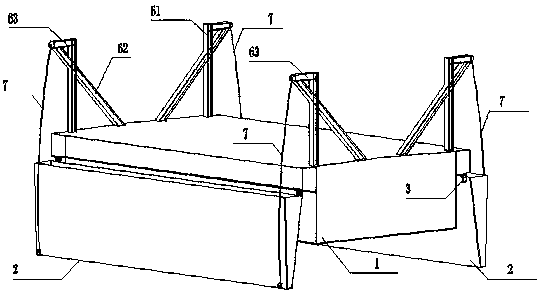

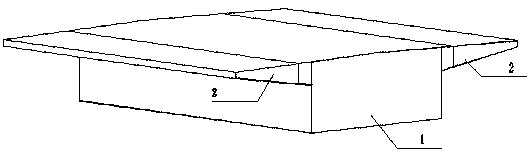

[0028] During the manufacture of super-wide steel box girder components of the bridge, the main unit and the wing unit are manufactured separately;

[0029] Temporarily connect the finished main unit and side wing unit through a pin device (the fixed lug is welded on the main unit, the rotating arm is welded on the side wing unit, and the fixed lifting lug and the rotating arm are fixed by a pin);

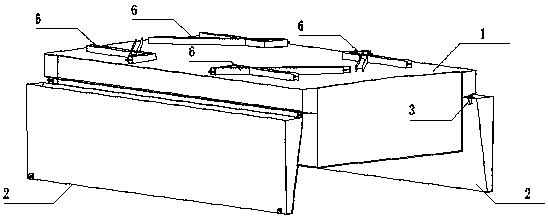

[0030] Place the finished bracket on the top surface of the main unit; the bracket is welded by columns, beams, slanting columns, and slanting braces;

[0031] The wing unit can rotate along the pin shaft. During transportation, the wing unit droops naturally, thereby reducing the width, which can solve the problem of over-width during the transportation of the steel box girder, thereby facilitating the passage through the gate;

[0032] Waiting for the ship to transport the super-wide steel box girder components of the bridge to the area to be installed, erect the bracket and weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com