Method for controlling width deviation of head and tail of hot rolled strip

A control method and hot-rolled strip technology, applied in the direction of metal rolling stand, metal rolling mill stand, etc., can solve the problem of tail loss of strip steel, wear of finishing rolling side guide plate and coiling side guide plate, overall width pull Narrow and other problems, to avoid equipment damage, solve the problem of ultra-wide, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

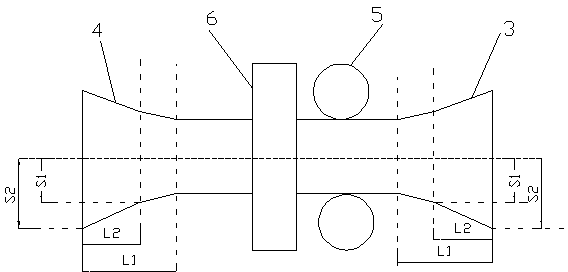

[0038] Regarding the narrowing of the width at the head and tail of the steel strip, Table 1 lists the setting values of the parameters used in Example 1 of this case.

[0039] Table 1

[0040] Short stroke parameter

a 0

L 3

L 4

S 3

S 4

L 1

L 2

S 1

S 2

Parameter setting value (mm)

1505

1478

591

1507

1511

1478

591

1507

1511

[0041] The short-stroke curve of the first strip steel tail that adopts for strip steel tail width narrowing can be obtained from Table 1:

[0042] b 1 =[(S 3 -a 0 ) L 3 / (L 3 -L 4 ) L 4 ]-[(S 4 -a 0 )(L 3 -L 4 ) / L 3 L 4 ]=[(1507-1505)1478 / (1478-591)×591]-[(1511-1505)(1478-591) / 1478×591]=-0.453858×10 -6

[0043] b 2 =[(S 4 -a 0 ) / L 3 L 4 ]-[(S 3 -a 0 ) / (L 3 -L 4 ) L 4 ]=[(1511-1505) / 1478×591]-[(1507-1505) / (1478-591)591]=3.05372×10 -6

[0044] the y 2 =1505+[-0.453858×10 -6 (1478-x 2 )+3.05372×10 ...

Embodiment 2

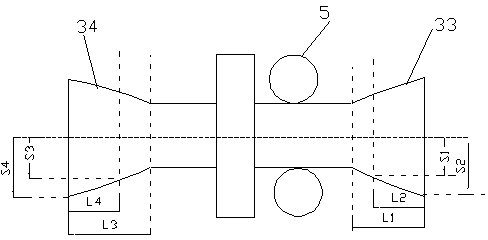

[0049] For the narrowing of the width at the head of the strip and the over-width at the tail, Table 2 lists the setting values of the parameters used in Example 2 of this case.

[0050] Table 2.

[0051] Short stroke parameter

a 0

L 5

L 6

S 5

S 6

L 1

L 2

S 1

S 2

Parameter setting value (mm)

1505

1478

665

1502.5

1495

1478

665

1507

1511

[0052] From Table 2, it can be obtained that the short-stroke curve y of the second strip tail used for the ultra-wide strip tail 3 and the short head stroke profile for strip head width reduction:

[0053] b 3 =[(S 5 -a 0 ) L 5 / (L 5 -L 6 ) L 6 ]-[(S6 -a 0 )(L 5 -L 6 ) / L 5 L 6 ]=[(1502.5-1505)1478 / (1478-665)×665]-[(1495-1505)(1478-665) / 1478×665]=1.437265×10 -6

[0054] b 4 =[(S 6 -a 0 ) / L 5 L 6 ]-[(S 5 -a 0 ) / (L 5 -L 6 ) L 6 ]=[(1495-1505) / 1478×665]-[(1502.2-1505) / (1478-665)665]=-5.55018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com