Spiral winding pipeline repairing device

A pipeline repair and spiral winding technology, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problem of reducing the repair speed of spiral winding pipe making by the fixed diameter method, unwinding equipment and grouting equipment. Unified movement and deployment and other problems, to achieve the effect of stable structural performance, convenient construction and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

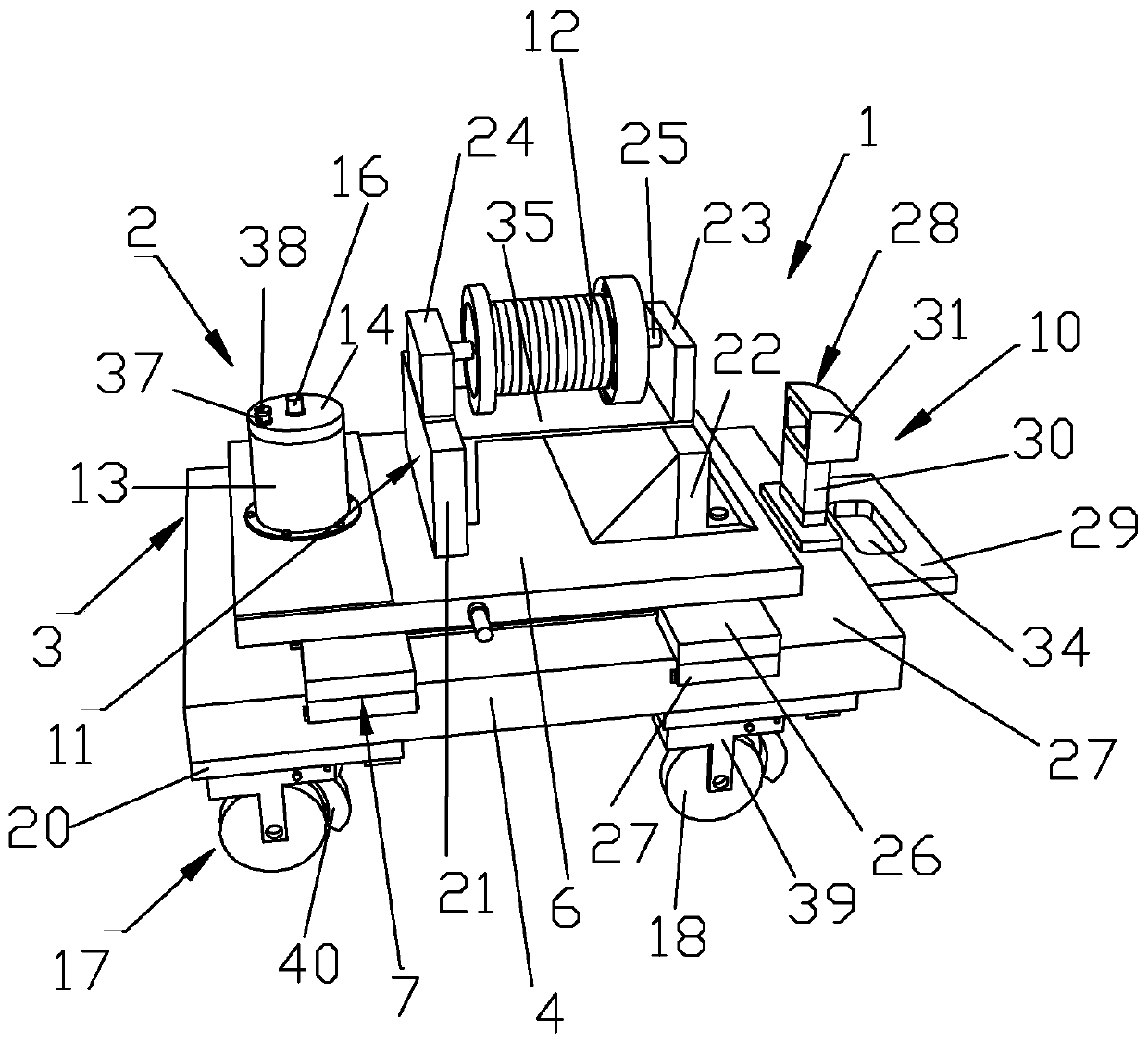

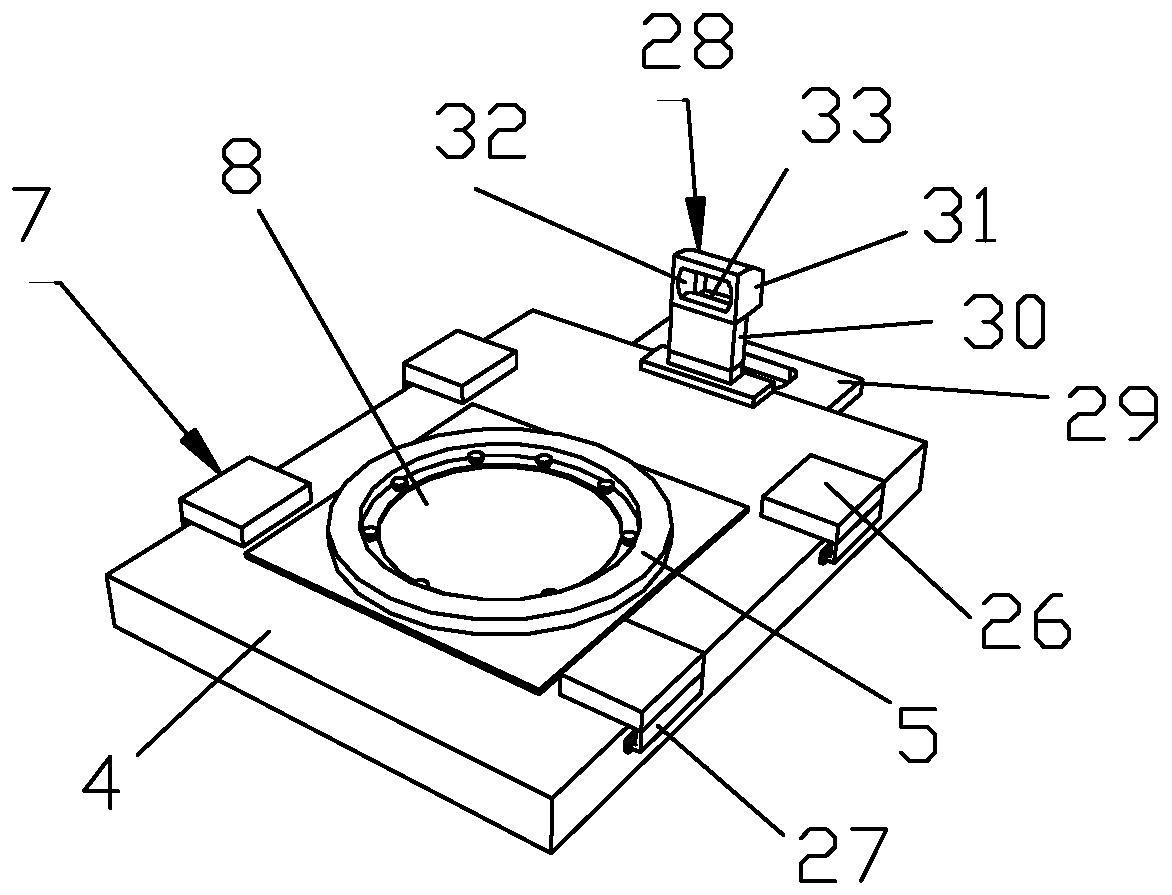

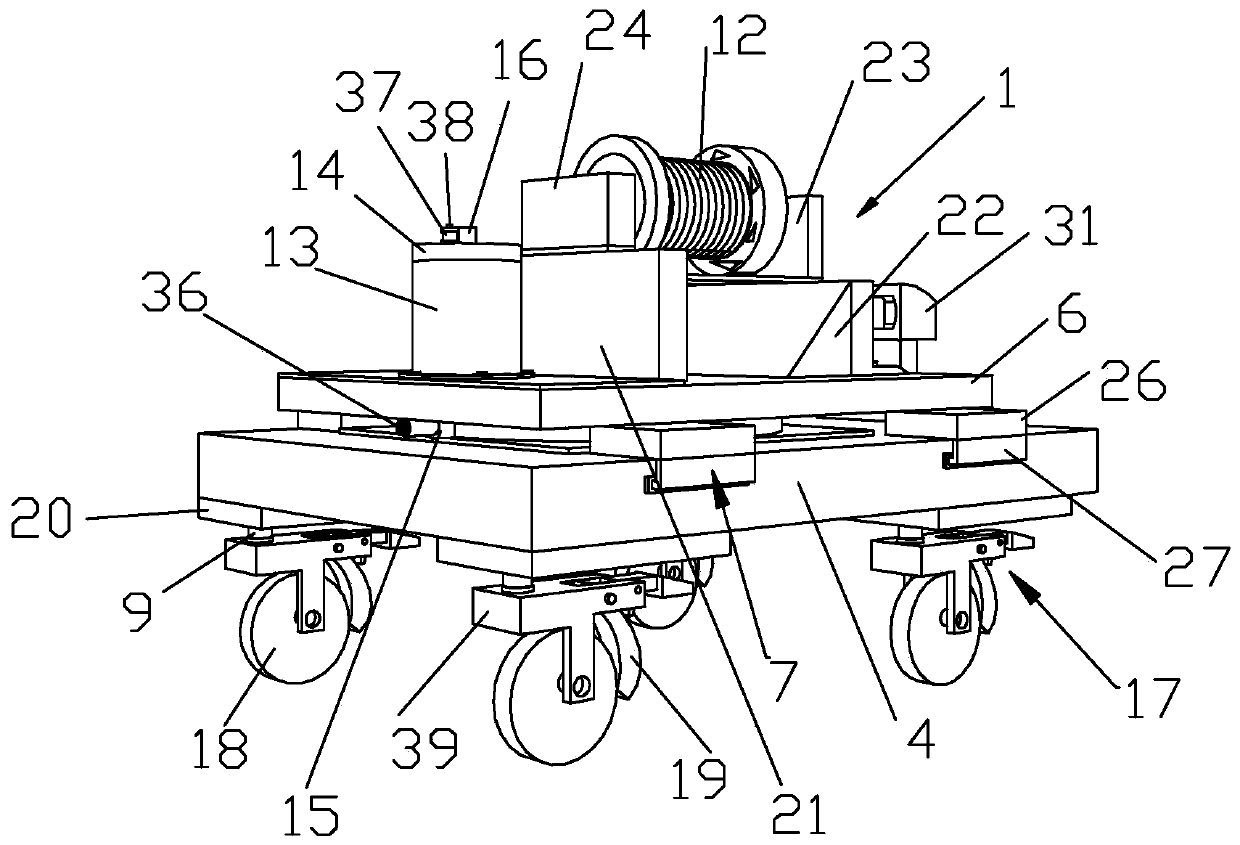

[0027] Such as Figure 1 to Figure 4 Shown here is a spiral wound pipe repair device of the present invention, which includes a winding machine assembly 1, a grouting assembly 2 and a connecting assembly 3. The connecting assembly 3 includes an operating table 4, a rotating disc 5, a total pad 6 and a supporting assembly 7 , The console 4 is provided with a mounting slot 8, a rotating disk 5 is installed in the mounting slot 8, the top of the rotating disk 5 is fixedly connected with a total backing plate 6, the total backing plate 6 is placed on the support assembly 7, the winding machine assembly 1 includes The lead-out device 10, the lifting device 11 and the drum 12, the lead-out device 10 is installed on the right side of the operation table 4, the lifting device 11 is installed on one side of the master plate 6, and the lifting device 11 is equipped with a drum 12 and a grouting component 2 Including a slurry cylinder 13, a cover plate 14, a water outlet pipe 15, and a mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com