Horizontal directional drilling crossing construction method and horizontal directional drilling crossing drilling device

A technology of horizontal directional drilling and horizontal directional drilling rig, which is applied in directional drilling, earthwork drilling, wellbore/well parts, etc. It can solve the problem of increasing the amount of bentonite and additives, prolonging the self-stabilization time of drilling, and being unsuitable for horizontal directional drilling, etc. problems, to achieve the effect of protecting the environment, reducing construction risks, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

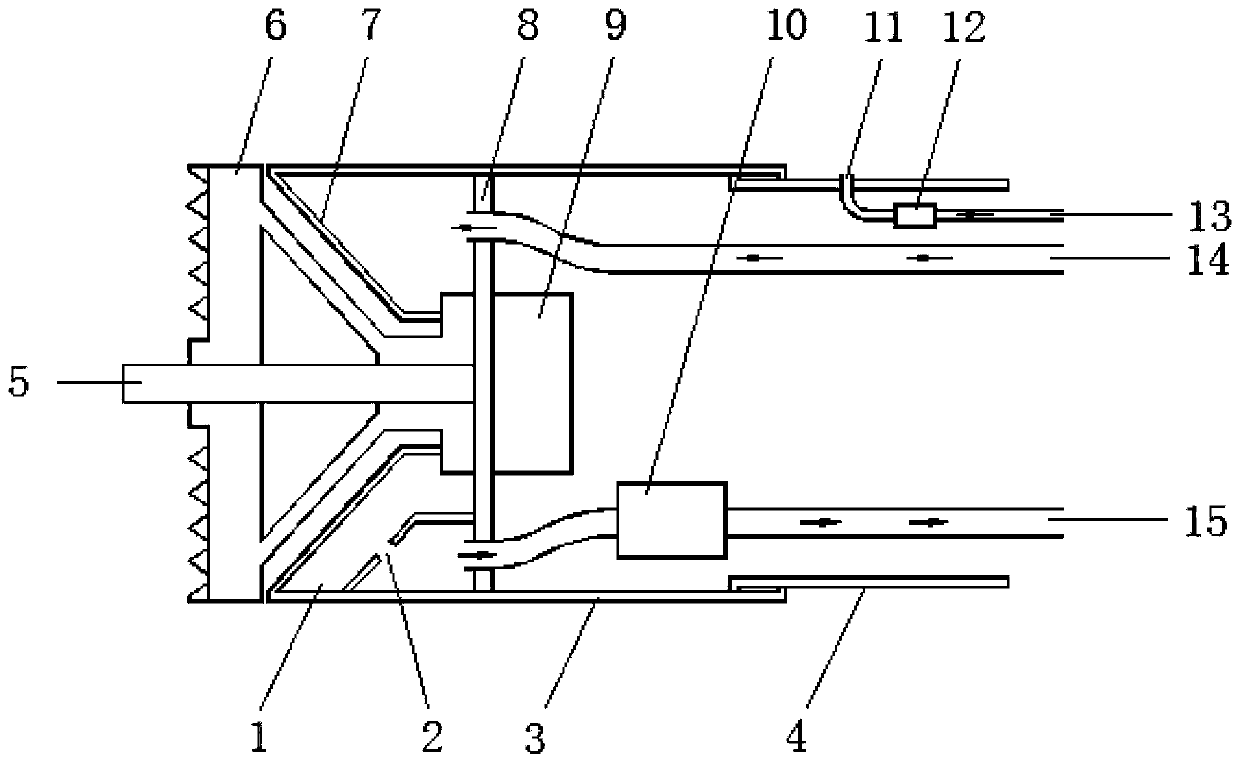

[0024] The strata traversed are silt and silty clay. First complete the preparatory work at the unearthed end. Lay water supply pipes, drainage pipes, grouting pipes and power supply lines in the crossing pipelines at the unearthed end; It is connected with the grouting pipe 13, and the crossing pipeline is welded with the pipe nipple 4 at the end of the drilling equipment. After the horizontal directional drilling machine completes the pilot hole operation, connect the drilling equipment at the excavation end. Use the horizontal directional drilling rig to pull the drill pipe, and use the drill pipe to pull the drilling equipment into the operation pit to start excavation. The drilling equipment cuts the formation to expand the drilling. The driving mechanism 9 (mud motor) drives the cutter head 6 to cut the formation, and the high-pressure mud required by the mud motor is provided by the horizontal directional drilling machine through the drill pipe. The mud is ejected f...

Embodiment 2

[0026] The strata traversed are silt sand, fine sand, medium sand and coarse sand. First complete the preparatory work at the unearthed end. Lay water supply pipes, drainage pipes, grouting pipes and power supply lines in the crossing pipelines at the unearthed end; It is connected with the grouting pipe 13, and the crossing pipeline is connected with the pipe nipple 4 at the end of the drilling equipment. After the horizontal directional drilling machine completes the pilot hole operation, connect the drilling equipment at the excavation end. Use the horizontal directional drilling rig to pull the drill pipe, and use the drill pipe to pull the drilling equipment into the operation pit to start excavation. The drilling equipment cuts the formation to expand the drilling. The driving mechanism 9 (mud motor) drives the cutter head 6 to cut the formation, and the high-pressure mud required by the mud motor is provided by the horizontal directional drilling machine through the ...

Embodiment 3

[0028] The strata traversed are silt sand, fine sand, medium sand and coarse sand. First complete the preparatory work at the unearthed end. Lay water supply pipes, drainage pipes, grouting pipes and power supply lines in the crossing pipelines at the unearthed end; It is connected with the grouting pipe 13, and the crossing pipeline is connected with the pipe nipple 4 at the end of the drilling equipment. After the horizontal directional drilling machine completes the pilot hole operation, connect the drilling equipment at the excavation end. Use the horizontal directional drilling rig to pull the drill pipe, and use the drill pipe to pull the drilling equipment into the operation pit to start excavation. The drilling equipment cuts the formation to expand the drilling. The drive mechanism 9 (motor) drives the cutter head 6 to cut the formation, and the motor is powered by the ground power supply device through the power supply line. The muddy water is injected by the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com