Self-lifting sliding and turnover construction system and construction method

A construction method and self-lifting technology, applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems of high labor intensity of slip-form construction workers, affecting construction quality, and high physical energy consumption of workers, so as to reduce the cost of manual mold overturning. Risks, reducing labor intensity of workers, and the effect of low labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

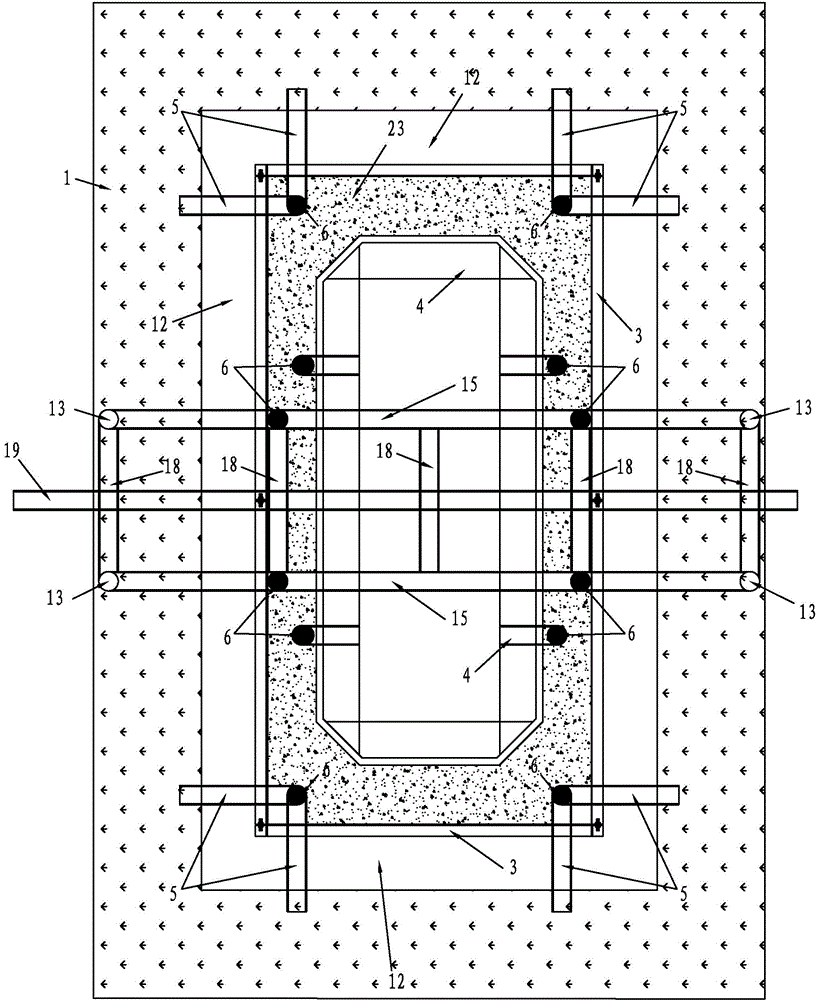

[0080] see figure 1 , in the present embodiment, the building body 23 is rectangular, and the self-elevating sliding system of the present invention includes an outer mold working disk 1 surrounding the outer periphery of the building body 23, and the bottom of the outer mold working disk 1 is provided with a double-layer auxiliary working disk 2, There is a certain distance between the inner side of the outer mold working disk 1 and the outer side of the building body 1 , and this distance is reserved for the hoisting channel 12 . A large-area steel formwork 3 is arranged close to the outside of the building body 23, and an inner mold sliding formwork frame 4 is arranged on the inside of the building body 3,

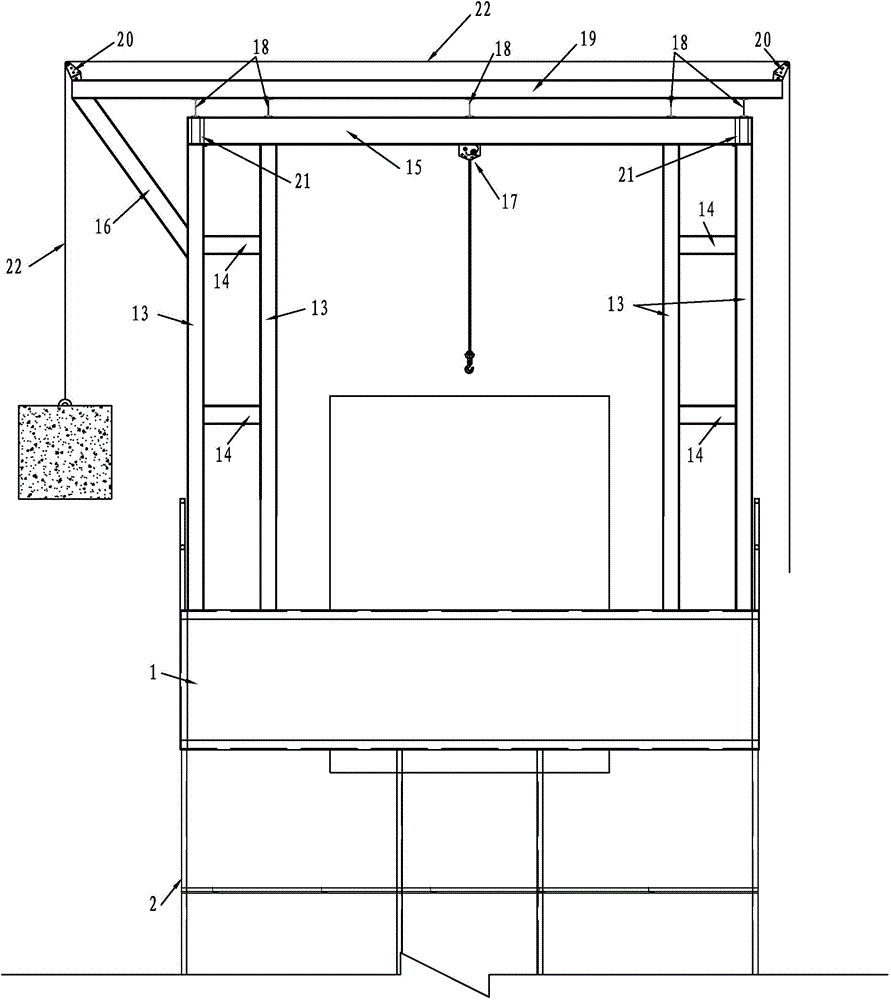

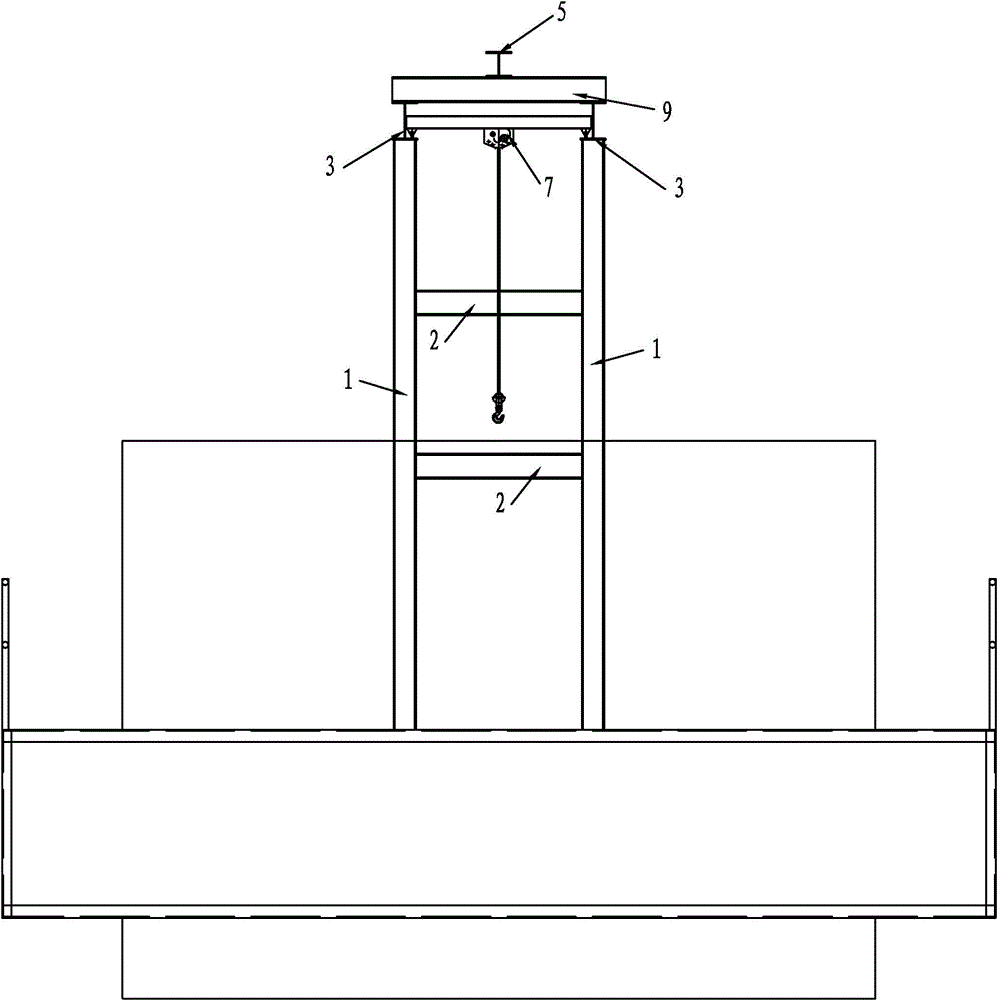

[0081] The self-elevating sliding turning system of the present invention includes a frame-type combined crane hanger device and a semi-automatic mold turning device. Among them, the frame-type combined crown crane hanger device spans the entire outer mold working plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com