Hole guiding device and hole guiding method for bad ground

A technology for complex strata and hole guides, applied in drilling equipment and methods, earthwork drilling, reciprocating drilling rigs, etc. , The effect of short hole forming time and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

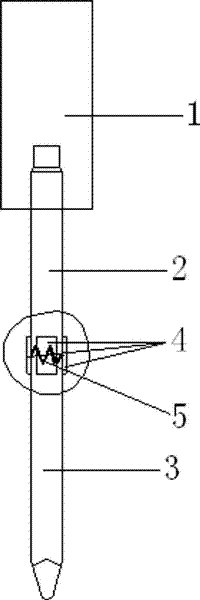

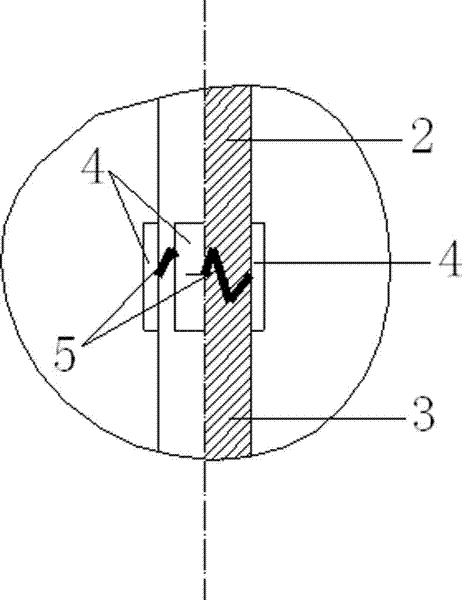

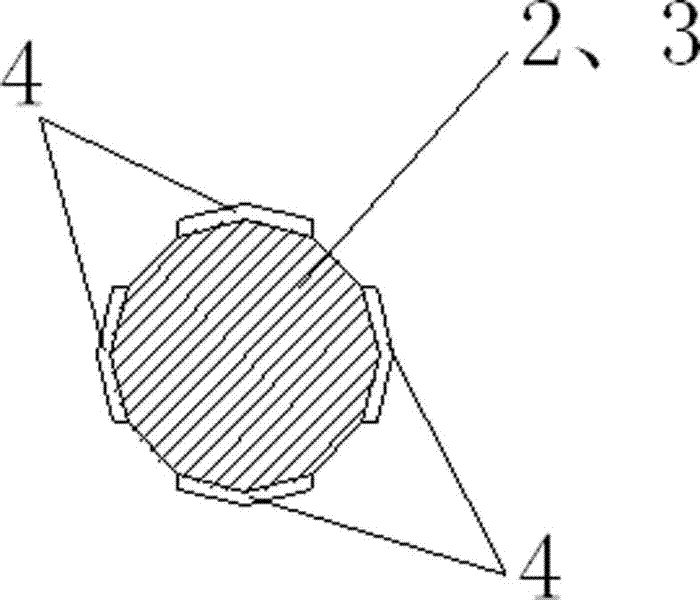

[0021] according to Figure 1-3 As shown, a hole guide for complex formations includes: a breaker main body 1, a first drill pipe 2, a second drill pipe 3 and a stiffening plate 4; the breaker main body 1 is connected to the first drill pipe 2, and a stiffening plate 4 is used 1. High-strength bolts or welds 5 connect the first drill pipe 2 and the second drill pipe 3 . The length of the drill pipe can be flexibly set depending on the thickness of the backfill layer.

[0022] The method for introducing holes in complex formations of the present invention has the following steps:

[0023] (1) In order to ensure that the welds are not on the same section, the first drill pipe 2 and the second drill pipe 3 are first cut into corresponding zigzag shapes, and on a flat ground, high-strength bolts or welds 5 are used to connect the drill pipes to form A whole;

[0024] (2) Determine the overall length of the drill pipe according to the depth of the hole to be introduced; in order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com