Self-elevating rotating crane installation device for tall towers

An installation device and self-elevating technology, applied in cranes and other directions, can solve the problems of high hoisting cost, long construction period, and inability to meet fast-paced installation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

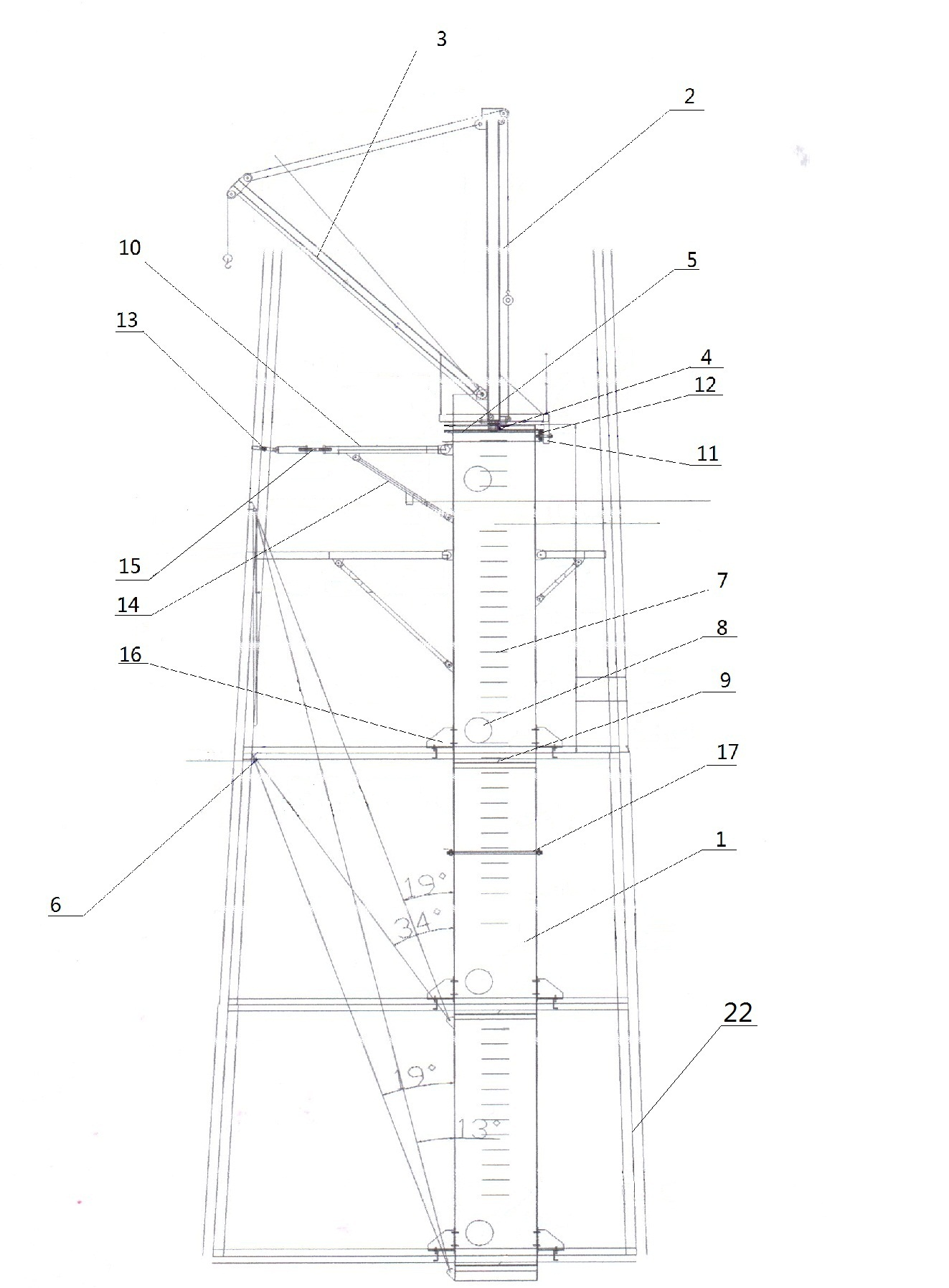

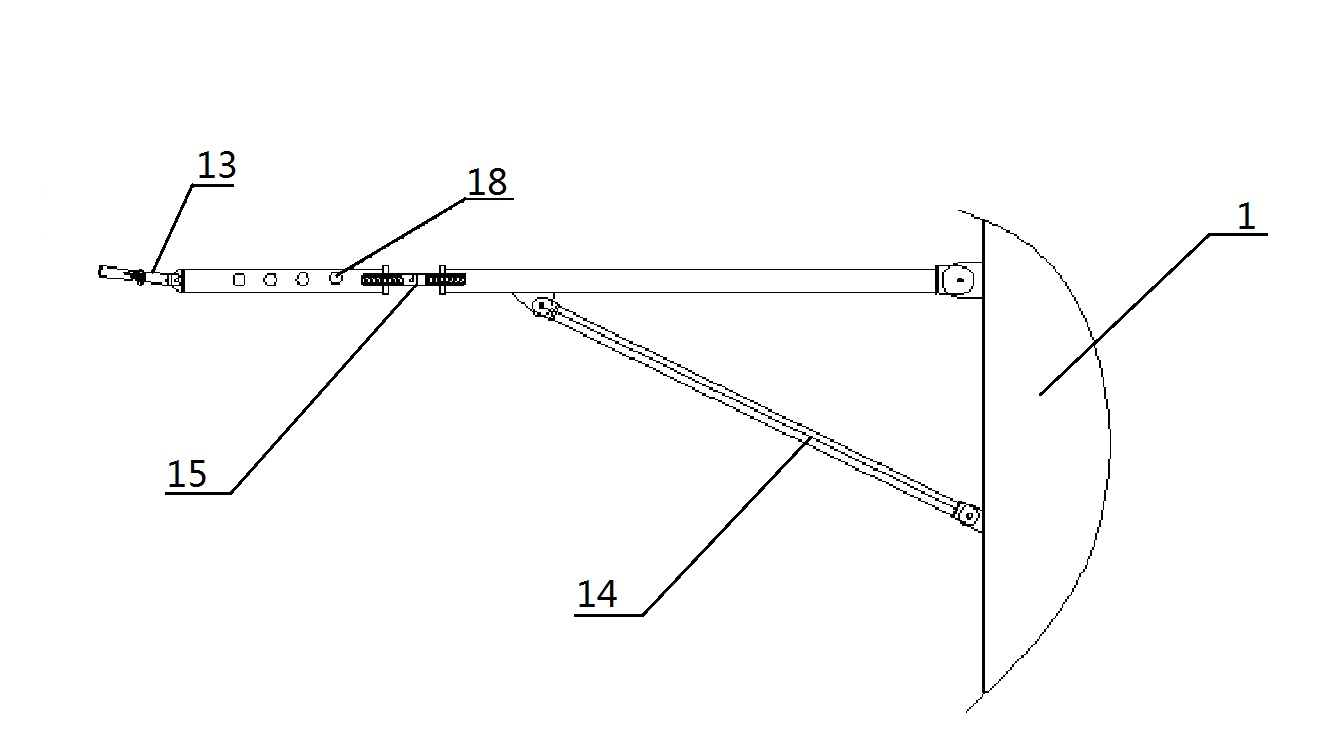

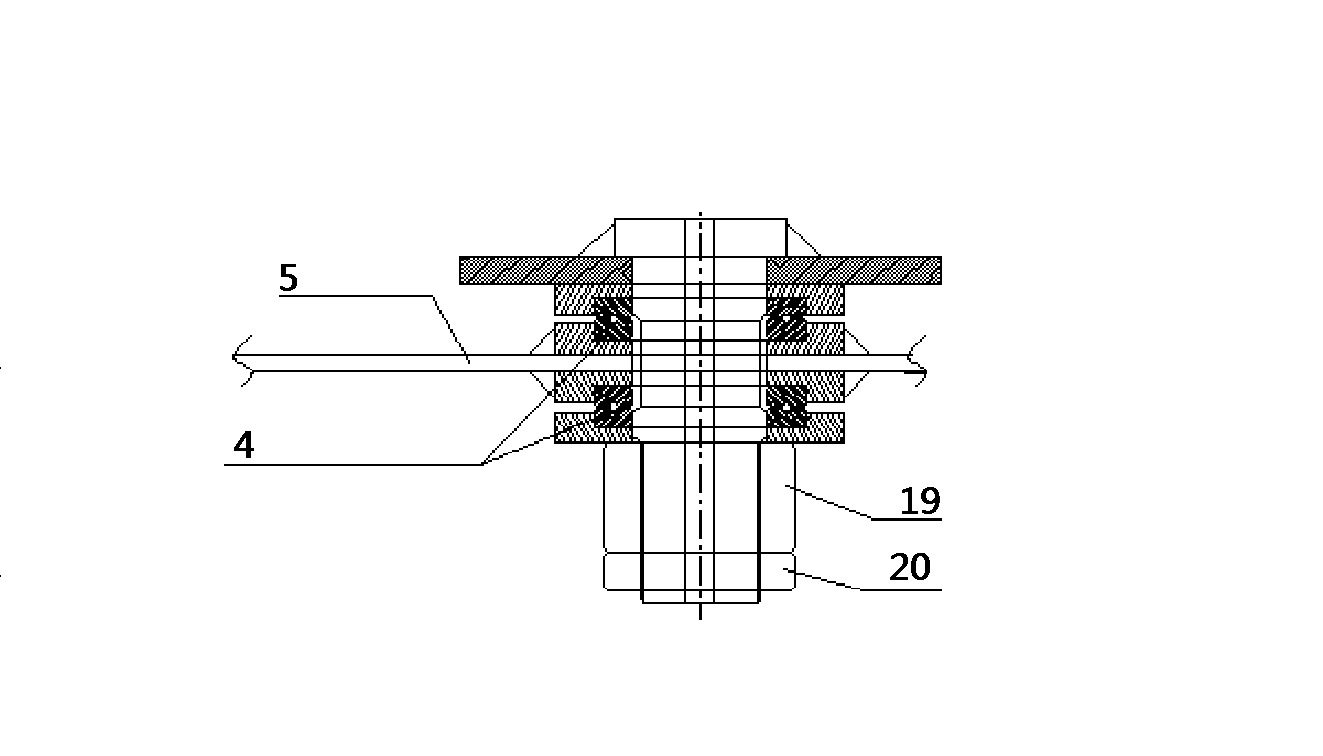

[0022] It is mainly composed of a central cylinder 1, a main mast 2, and an auxiliary mast 3. It is characterized in that the main mast 2 is located on the top of the central cylinder 1, and the connection between the main mast 2 and the central cylinder 1 is provided with a plane thrust ball bearing 4. The main mast 2 and the plane The thrust ball bearing 4 is fixed on the top plate 5 of the central cylinder 1 through nuts 19, the main mast 2 is connected with the auxiliary mast 3, the central cylinder 1 is connected with the tower beam 6, a ladder 7 is arranged on the central cylinder 1, and a ladder 7 is arranged on the central cylinder. 1 is provided with an operation hole 8 on the cylinder, and a platform 9 is provided inside the center cylinder 1. The disposal of the platform 9 is adapted to the operation hole 8, and an operation platform 10 is provided on the outer edge of the top of the center cylinder 1.

[0023] The connection between the main mast 2 and the top plate...

Embodiment 2

[0028] The present invention makes full use of the structural characteristics of the tower to make a φ1520mm×6mm steel coil pipe with a length of 17m as the center tube support. The center tube 1 is divided into two sections from the middle and connected by a flange 17 for the convenience of installation and removal. Use a crane to hoist the lower central tube 1 into the tower, center it with the adjusting screw 15, connect the central tube 1 with the tower beam 6 on the tower 22 with a corbel and fix it firmly, and then hoist the upper section into the tower and the lower section After connecting and fixing, the top platform and mast are installed; the 3-ton hoist is in place on the ground, fixed, and threaded with wire ropes; A Φ219×10 high 6m seamless steel pipe is erected on the top of the central tube 1 as the main mast 2, and a Φ159×10 long 6m seamless steel pipe is used as the auxiliary mast 3. Two pairs of planar thrust ball bearings 4 are installed at the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com