Method for installing blast furnace single-tube downcomer

An installation method and a single-pipe technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of large-scale machinery use, difficulty in unified command, and easy danger, so as to improve the construction process and overcome the narrow construction site Restraint, the effect of ensuring the quality of the installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0030] A method for installing a blast furnace single-pipe downcomer, comprising the following steps:

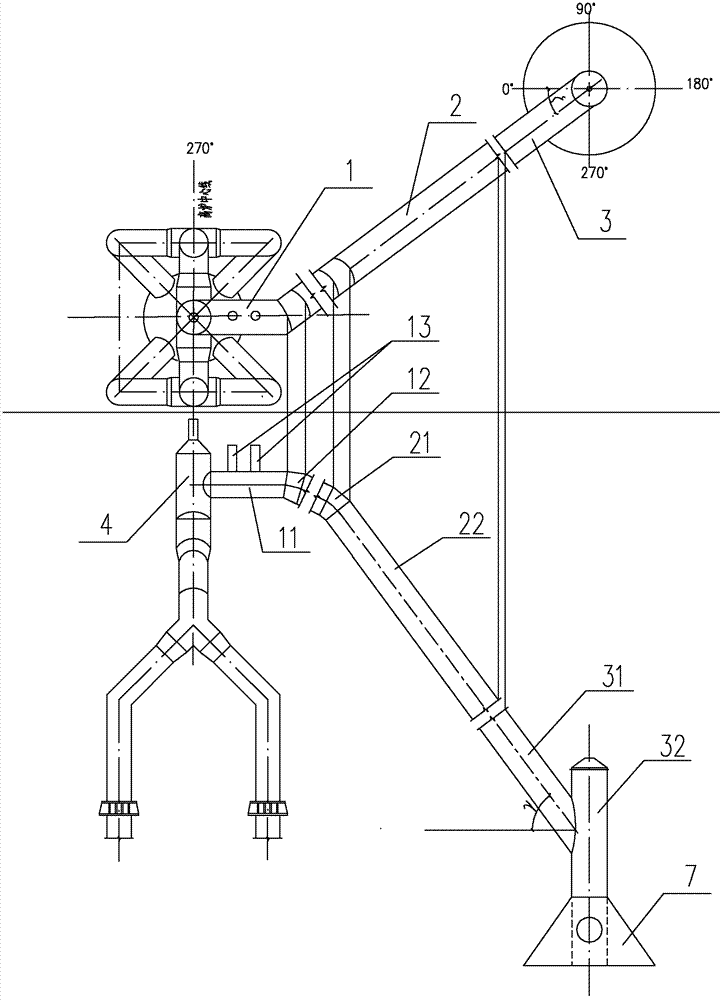

[0031] 1. Hoisting preparation

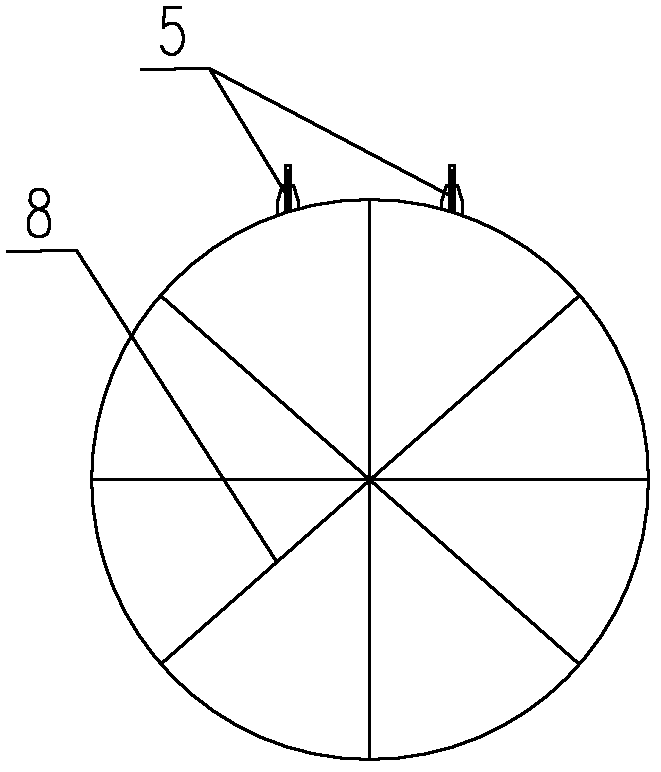

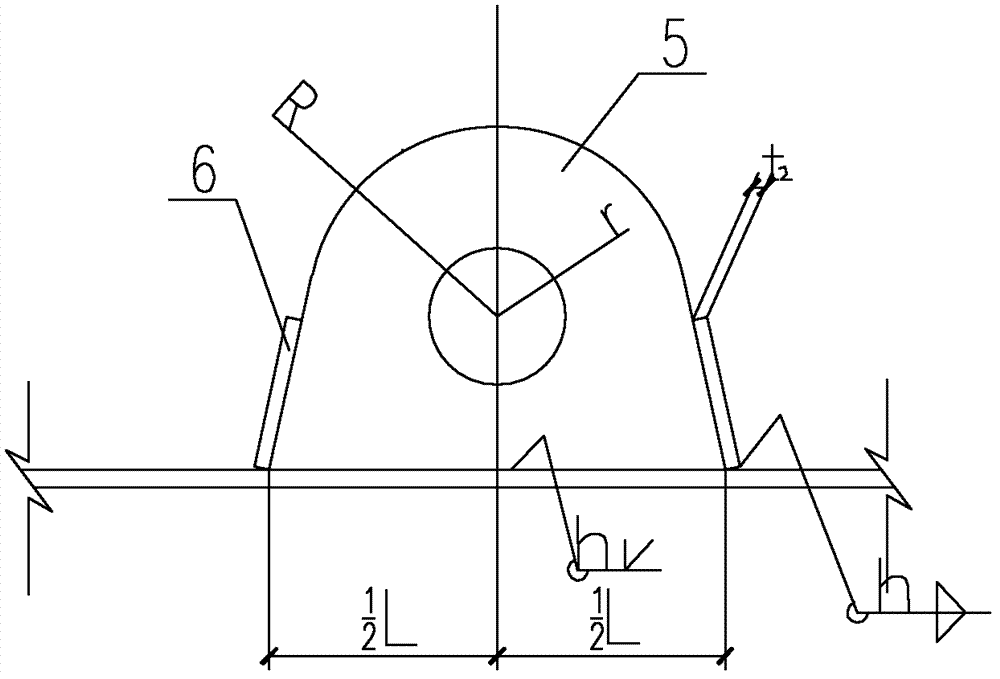

[0032] 1) Division of hoisting units: According to the division of downpipe manufacturing units and the conditions of the on-site assembly site, combined with the transportation capacity of the vehicle and the hoisting performance of the hoisting machinery, the number of hoisting units and the assembly size of each hoisting unit are determined. In this embodiment, the single pipe The downcomer is divided into three large hoisting units, the upper shaker 1, the middle section 2 and the lower tee 3, please refer to figure 1 and Figure 4 The upper swing head 1 includes a straight pipe section 11, a lower elb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com